Flocculating agent feeding device of sewage treatment tank for sewage treatment

A sewage treatment tank, sewage treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. problems, to achieve the effect of saving manpower, convenient use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

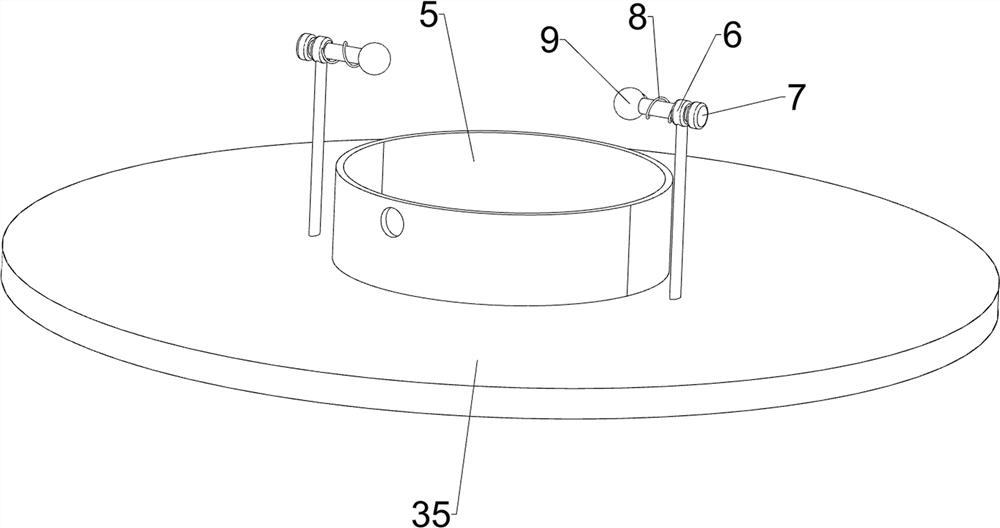

[0022] A kind of flocculant feeding device of the sewage treatment tank for sewage treatment, such as Figure 1-6 As shown, it includes a mounting plate 1, a blanking assembly 2, a rotating assembly 3 and a delivery assembly 4. The mounting plate 1 is provided with a blanking assembly 2 for blanking by sliding, and the mounting plate 1 is provided with a rotating assembly. The rotating assembly 3 that rotates in a rotating manner, and the mounting plate 1 is provided with a throwing assembly 4 that is thrown in a rotating manner.

[0023] When using the device to inject flocculant, the staff puts the flocculant to be injected into the feeding component 2 for discharging, and then injects the flocculant into the sewage treatment tank through the input component 4. During the inputting process, the staff The device can be rotated by rotating the assembly 3, which is more convenient for people to use and improves people's work quality.

[0024] Such as figure 1 , figure 2 and...

Embodiment 2

[0031] On the basis of Example 1, such as figure 1 , Figure 5 and Figure 6 As shown, it also includes a cylinder 5, a third guide sleeve 6, a fourth slide rod 7, a fifth spring 8 and a sphere 9, the cylinder 5 is placed in the middle of the disc 35, and the front and rear sides of the disc 35 are welded with the first Three guide sleeves 6, the third guide sleeve 6 are all slidingly provided with a fourth slide bar 7, the fifth spring 8 is connected between the fourth slide bar 7 and the third guide sleeve 6, and the inner end of the fourth slide bar 7 All are welded with spheroid 9, and spheroid 9 cooperates with feeding hopper 45.

[0032] When throwing in the flocculant, when the hopper 45 rotates to contact with the sphere 9, the hopper 45 collides with the sphere 9 to vibrate, thereby shaking the flocculant stuck on the hopper 45 into the cylinder 5, and the hopper 45 The rotation pushes the ball 9 to move outward, and the fourth sliding rod 7 slides outward in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com