Welding clamp device for hoisting section of steel plate composite beam bridge and clamping method of welding clamp device

A welding jig and jig device technology, applied in the field of steel plate girder bridge manufacturing, can solve the problems of non-destructive testing and construction quality affecting the welding quality of the ring seam of the bridge position of the hoisting segment, the difficulty of on-site welding operations, and the large number of parts, etc. Improve on-site welding quality, safe and reliable use, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

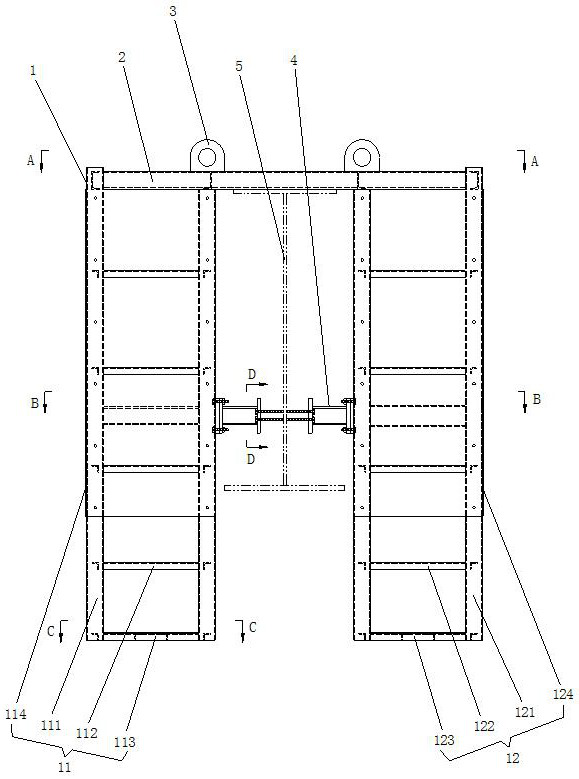

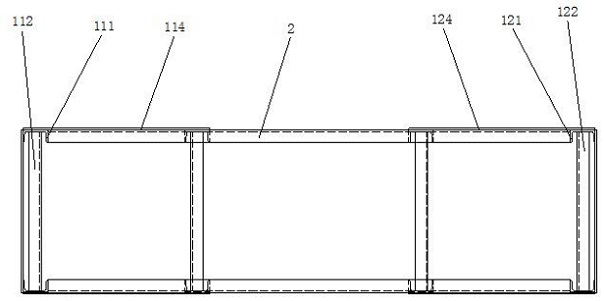

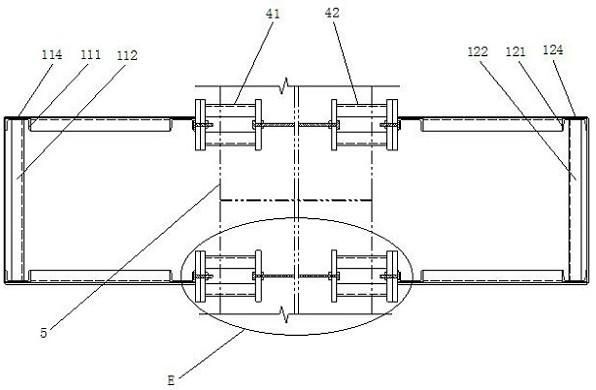

[0032] Such as Figures 1 to 7 As shown, the steel plate composite girder bridge hoisting section welding fixture device of the present invention includes a stand 1 , a beam 2 , a lug plate 3 and a clamping mechanism 4 .

[0033] The stand 1 is vertically placed and includes a first stand 11 and a second stand 12 , the first stand 11 and the second stand 12 have identical structures and are arranged symmetrically to each other.

[0034]The first stand 11 is a cuboid frame structure and is composed of four first columns 111, a first ladder 112, a first back cover 113 and a first baffle 114; The upper ends of the two first columns 111 on the left side of a stand 11 are higher than the upper ends of the two first columns 111 on the right side of the first stand 11; A plurality of first ladders 112 are horizontally connected between two adjacent first columns 111, and the plurality of first ladders 112 are evenly distributed from top to bottom; end; the first baffle 114 is match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com