All-round metal smelting slag salvaging robot

A robot and metal technology, applied in metal processing equipment, manipulators, mechanical cleaning, etc., can solve the problems of inability to comprehensively grasp smelting furnace scum, large safety risks, and inaccurate grasping, and increase the scope of equipment application. , Improve the accuracy of grasping, the effect of high running accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

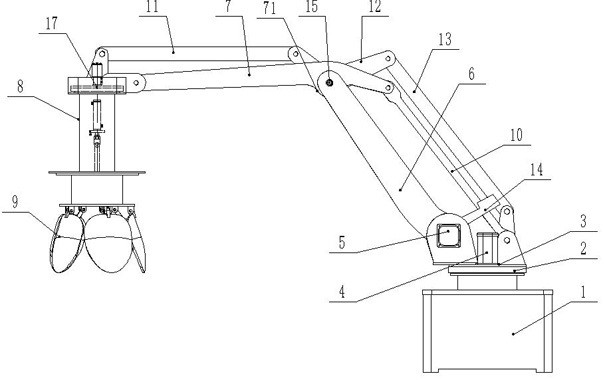

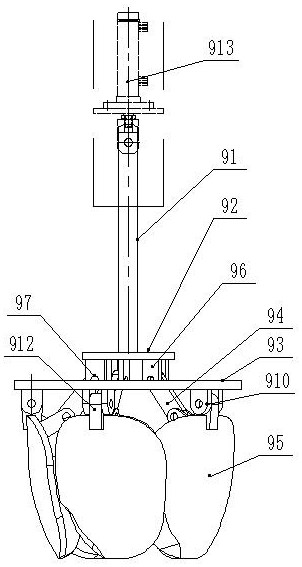

[0044] like Figure 1-5 As shown together, this embodiment provides an all-round robot for metal smelting and slag removal, including a grasping mechanism for performing slag removal, an operating mechanism that drives the grasping mechanism to move in multiple directions, and maintains the grasping mechanism to keep vertical during the movement process. The balance mechanism; one end of the operating mechanism is fixed on the base 1, and the other end is connected to the grasping mechanism. One end of the balance mechanism is connected to the grasping mechanism, and the other end is connected to the base 1. Institutional connections.

[0045] The base 1 is fixed on the ground, and a slewing support 2 is installed on the slewing support 2, and a slewing disk 3 is installed on the slewing support 2; the slewing support 2 is connected with the first servo motor 4, and the first servo motor 4 Drive the slewing bearing 2 to drive the slewing disk 3 to rotate, so that the equipmen...

Embodiment 2

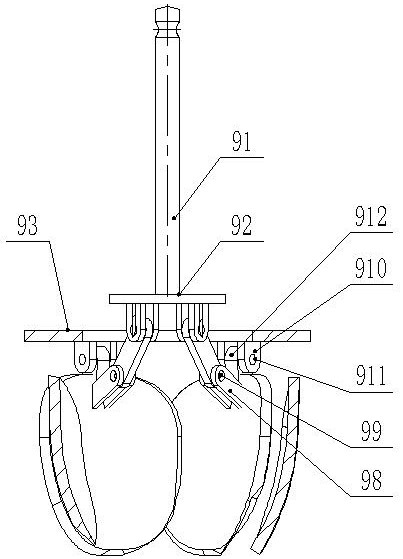

[0067] like Figure 6-7 As shown together, this embodiment provides an all-round metal smelting slag removal robot. The difference between this embodiment and Embodiment 1 is that the gripping mechanism is a split gripper assembly 16, and the split gripper The hand assembly 16 includes two grippers 161 arranged symmetrically. The two grippers 161 are connected with the opening and closing mechanism 162, and the opening and closing are realized through the opening and closing mechanism 162. The opening and closing mechanism 162 is connected with the telescopic rod of the oil cylinder 163 The opening and closing mechanism 162 is driven by the oil cylinder 163 to open and close the split handle assembly 16; the oil cylinder 163 is fixed in the telescopic arm 8.

[0068] The opening and closing mechanism 162 is arranged on a fixing frame 165 , and the fixing frame 165 is fixed on the connecting arm 8 so as to be connected to the running mechanism via the split handle assembly 16 ....

Embodiment 3

[0072] like Figure 8 As shown, this embodiment provides an all-round robot for metal smelting and slag removal. The difference between this embodiment and Embodiment 2 is that both the gripper 161 and the slag removal gripper 164 are toothed structures.

[0073] The slag removal robot described in the present invention can use hydraulic, electric, pneumatic, and mechanical powers to realize remote control operation, realize automatic operation, and realize long-distance slag removal; it is mainly suitable for steel, iron, copper, aluminum, and various non-ferrous metals, smelting Process waste removal.

[0074] The setting of the operating mechanism in the present invention can be driven by the second servo motor and driven by the four-bar linkage mechanism jointly formed by the big arm, the small arm, the pull rod and the rotary disk, so that the grabbing mechanism can move up and down, forward and backward, so as to Adjust the accurate grabbing position, grab the scum in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com