Postoperative instrument cleaning and disinfecting machine

A technology for cleaning and disinfecting instruments, applied in the direction of disinfection, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of small number of instruments, consume a lot of time, and low efficiency, so as to improve efficiency, save time and cost, Guaranteed safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

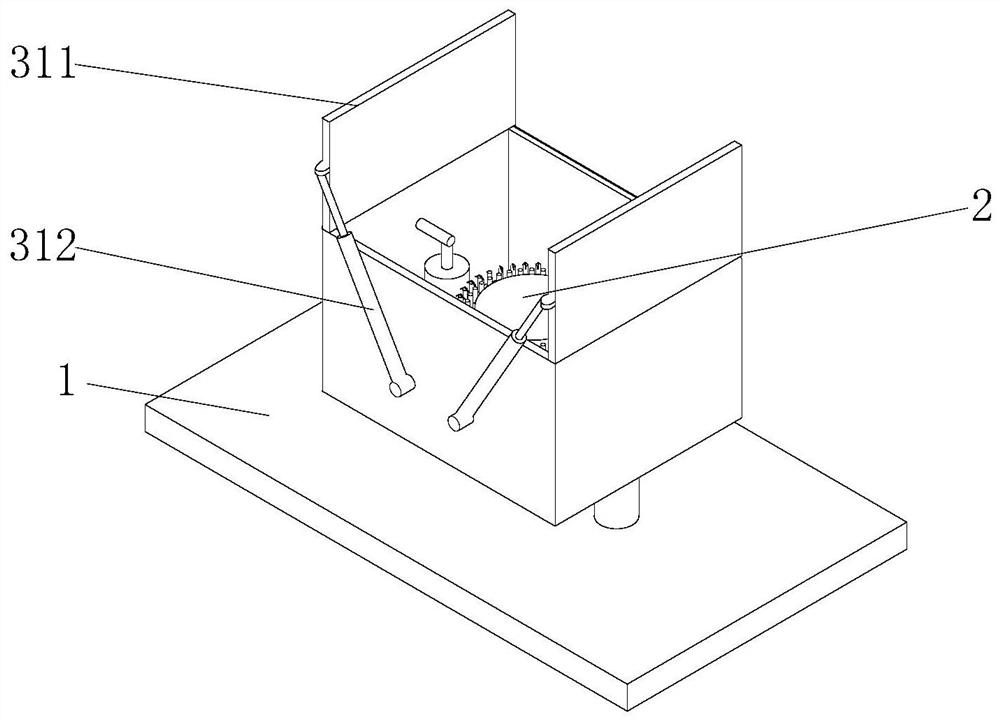

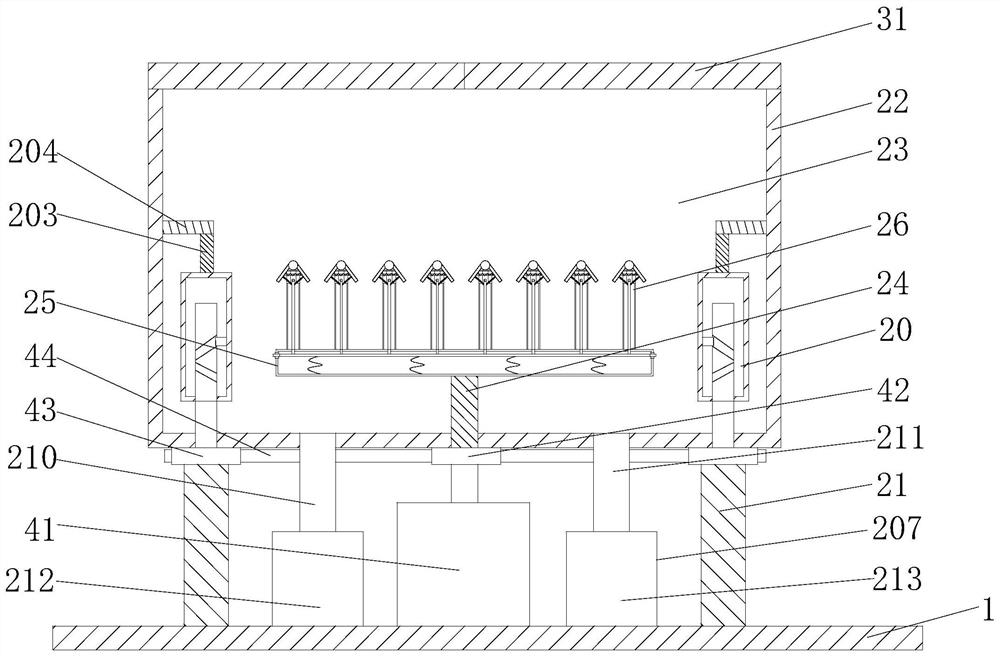

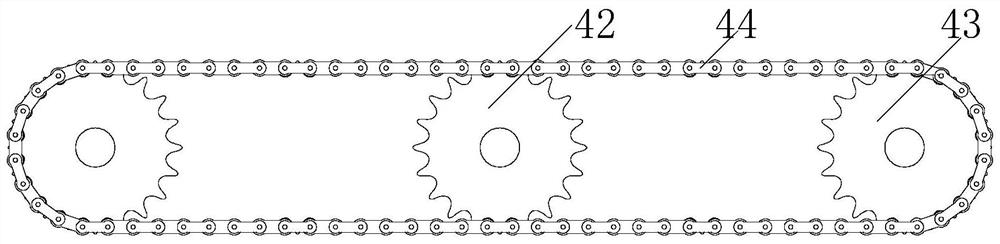

[0030] Such as Figure 1 to Figure 6 As shown, a postoperative instrument cleaning and disinfection machine includes a base plate 1, a disinfection device 2 and a rotating device 4, the base plate 1 is fixedly equipped with a rotating device 4, and the rotating device 4 is connected with a disinfection device 2; during specific work, Put the postoperative instruments into the disinfection device 2 at one time, the rotating device 4 starts to drive the disinfection device 2 to rotate in the disinfectant 23, and the cleaning roller 202 rubs and cleans the surface of the postoperative instruments. After cleaning, ultraviolet radiation The lamp heats and irradiates it for a long time, and after the disinfectant 202 on its surface evaporates, the machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com