Tridentate ligand modified silica gel immobilized platinum-containing hydrosilylation catalyst and preparation method thereof

A platinum catalyst and hydrogen addition technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor applicability and low reusability, Achieve the effects of high mechanical strength, low production cost, good chemical stability and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

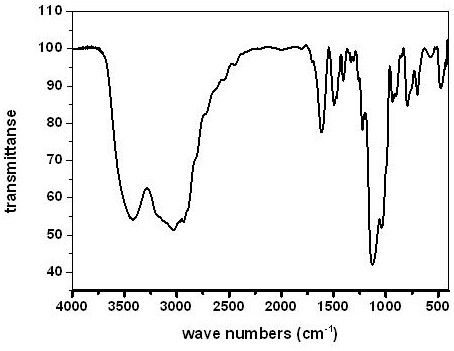

[0031] Step 1 Preparation of Tridentate Ligand Modified Silica Gel

[0032] Add 300 parts of commercially available silica gel to 5000 parts of absolute ethanol and disperse evenly to obtain a silica gel suspension; then add 30 parts of an organic bidentate ligand to the silica gel suspension, stir and react at 80 °C for 8 h, and the reaction is complete After filtering and washing the solid product with 1000 parts of ethanol, the product was vacuum-dried to obtain a tridentate ligand-modified silica gel;

[0033] Step 2 Preparation of Tridentate Ligand Modified Platinum Catalyst on Silica Gel

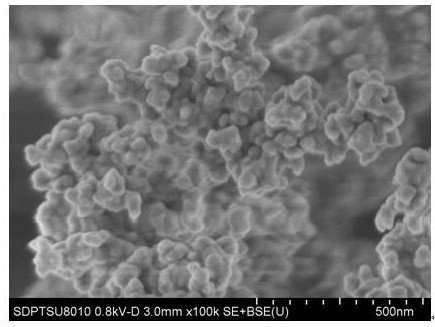

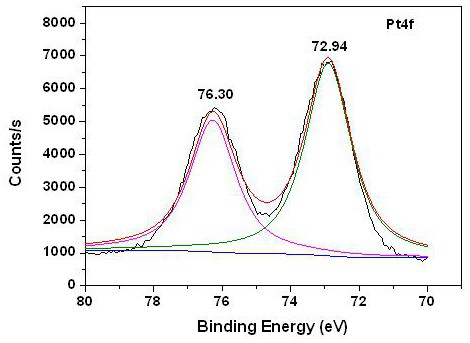

[0034] 3 parts of Pt(COD)Cl 2 Dissolve in 100 parts of ethanol, then add the tridentate ligand-modified silica gel prepared in step 1 and disperse evenly, react at 80 °C for 6 h under the protection of normal pressure nitrogen, filter and wash the solid with a solvent after the reaction is complete, and dry it in vacuum. A tridentate ligand-modified silica gel-supported platinum-cont...

Embodiment 2

[0044] Step 1 Preparation of Tridentate Ligand Modified Silica Gel

[0045] Add 100 parts of commercially available silica gel to 5000 parts of absolute ethanol and disperse evenly to obtain a silica gel suspension; then add 30 parts of an organic bidentate ligand to the silica gel suspension, stir and react at 40 °C for 20 h, and the reaction is complete After filtering and washing the solid product with 1000 parts of ethanol, the product was vacuum-dried to obtain a tridentate ligand-modified silica gel;

[0046] Step 2 Preparation of Tridentate Ligand Modified Platinum Catalyst on Silica Gel

[0047]3 parts of Pt(COD)Cl 2 Dissolve in 100 parts of ethanol, then add the tridentate ligand-modified silica gel prepared in step 1 and disperse evenly, react at 40 °C for 18 h under the protection of normal pressure nitrogen, filter and wash the solid with a solvent after the reaction is complete, and dry in vacuo The structure of the tridentate ligand-modified silica gel-supporte...

Embodiment 3

[0051] Step 1 Preparation of Tridentate Ligand Modified Silica Gel

[0052] Add 300 parts of commercially available silica gel to 5000 parts of absolute ethanol and disperse evenly to obtain a silica gel suspension; then add 30 parts of organic bidentate ligands to the silica gel suspension, stir and react at 120 °C for 8 hours, after the reaction is completed Filtrate and wash the solid product with 1000 parts of ethanol, and dry the product in vacuum to obtain a novel tridentate ligand-modified silica gel;

[0053] Step 2 Preparation of Tridentate Ligand Modified Platinum Catalyst on Silica Gel

[0054] 3 parts of Pt(COD)Cl 2 Dissolve in 100 parts of ethanol, then add the tridentate ligand-modified silica gel prepared in step 1 and disperse evenly, react at 120 °C for 4 h under the protection of normal pressure nitrogen, filter and wash the solid with a solvent after the reaction is complete, and dry in vacuum The tridentate ligand-modified silica gel-supported platinum-co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com