Efficient stirring device for food production

A stirring device and high-efficiency technology, which is applied in the field of high-efficiency stirring devices for food production, can solve problems such as low efficiency and poor stirring effect, and achieve good scraping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

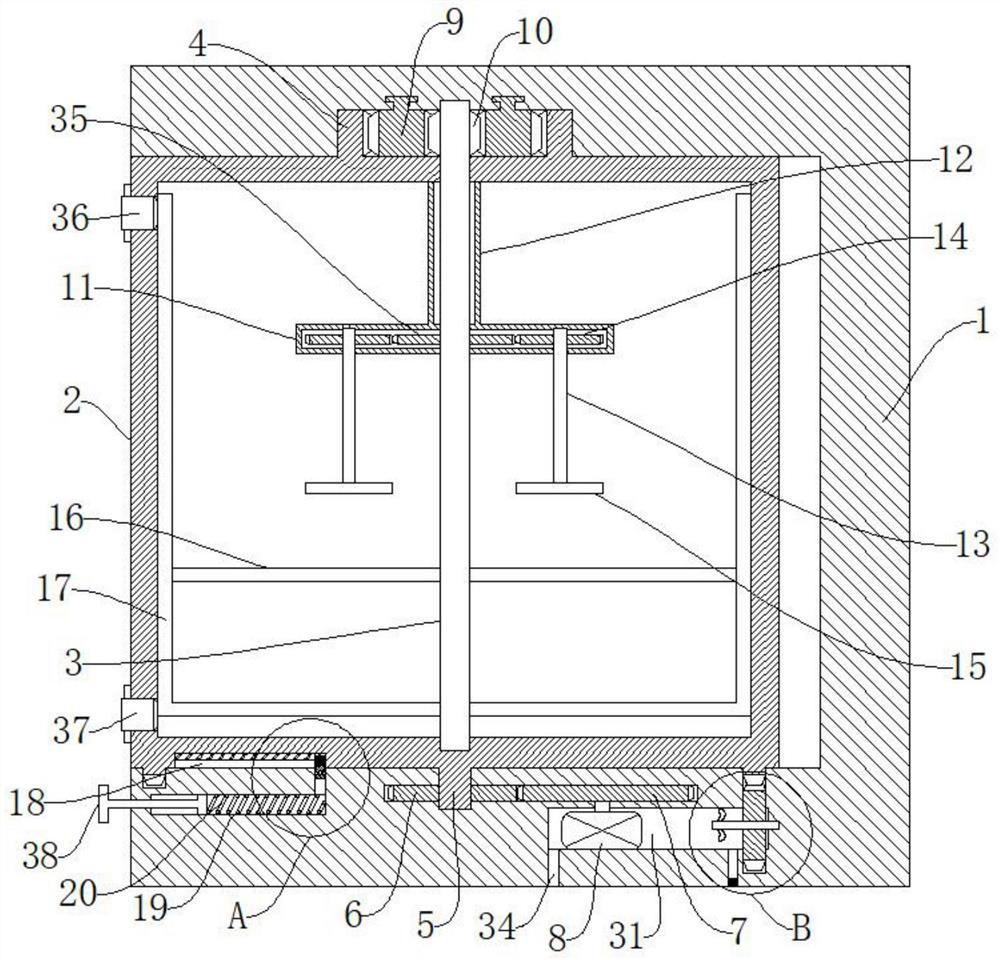

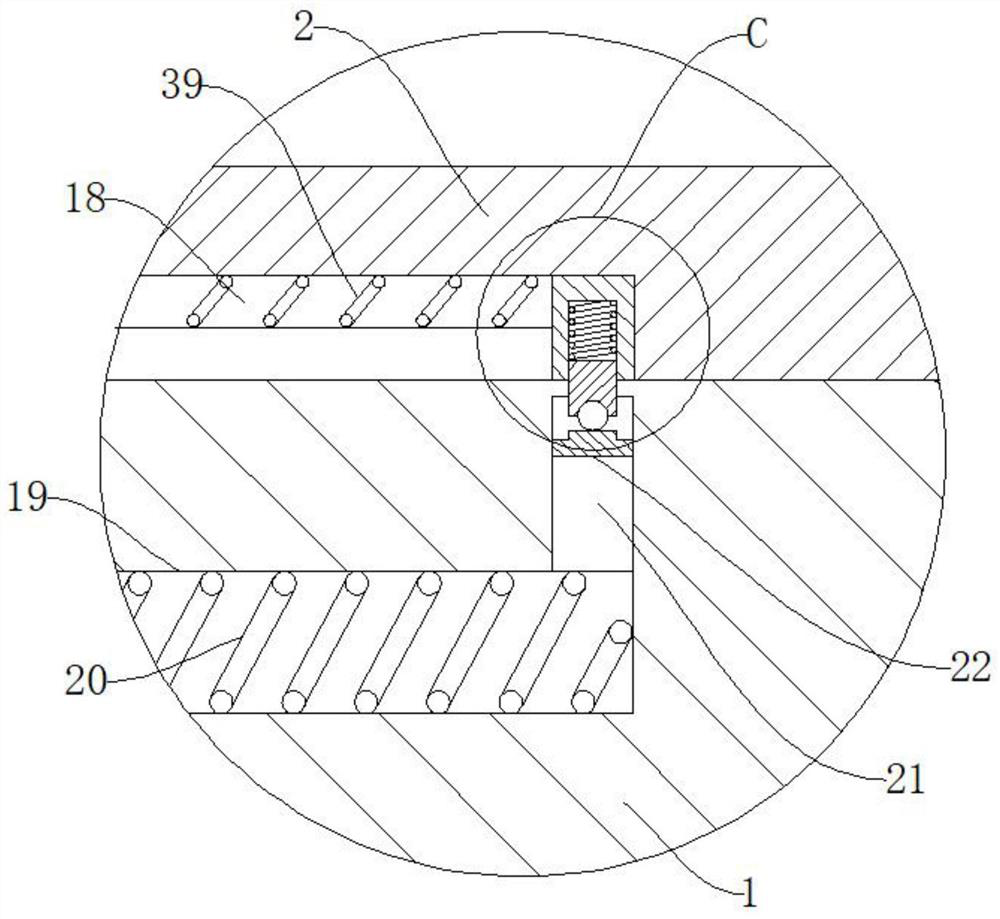

[0031] refer to figure 1 , figure 2 , a high-efficiency mixing device for food production, comprising a support member 1 and a mixing cylinder 2, the mixing cylinder 2 is located in the support member 1, the mixing cylinder 2 is connected to the support member 1 in rotation, the bottom end of the support member 1 is provided with a placement groove 31, and placed The groove 31 is connected with a driving motor 8, the output end of the driving motor 8 is fixedly connected with the driving gear 7, the bottom end of the mixing cylinder 2 is fixedly connected with the transmission shaft 5, and the transmission shaft 5 is fixedly connected with the driven gear 6, and the driven gear 6 and The driving gear 7 is meshed, the upper end of the mixing cylinder 2 is fixedly connected with a transmission ring 4, and the transmission ring 4 is rotatably connected with the support member 1 .

[0032] When using this device, the feed port 36 is opened, and the raw materials to be mixed are ...

Embodiment 2

[0037] refer to figure 1 , a high-efficiency stirring device for food production, which is basically the same as that of Example 1, furthermore: the transmission ring 4 is connected with a planetary gear 9, the planetary gear 9 is connected to the support member 1 in rotation, and the inner wall of the transmission ring 4 is fixedly connected with a fixed The fixed teeth are meshed with the planetary gear 9, the first rotating shaft 3 is rotatably connected in the mixing cylinder 2, the upper end of the first rotating shaft 3 is fixedly connected with the first transmission gear 10, and the first transmission tooth 10 is meshed with the planetary gear 9, so that The rotation direction of the first rotating shaft 3 is opposite to the rotation direction of the mixing drum 2, which is conducive to improved stirring.

Embodiment 3

[0039] refer to figure 1 , a high-efficiency stirring device for food production, which is basically the same as that of Example 1, furthermore: the first rotating shaft 3 is sleeved with a fixed cylinder 12, one end of the fixed cylinder 12 is fixedly connected with the mixing cylinder 2, and the fixed cylinder 12 is far away from the mixing cylinder. One end of the cylinder 2 is fixedly connected with a rotating plate 11, and the rotating plate 11 is rotatably connected with the first rotating shaft 3. The rotating plate 11 is rotatably connected with multiple groups of rotating rods 13, and the bottom end of the rotating rod 13 is fixedly connected with a stirring rod 15, which is convenient for mixing. The raw materials in the cylinder 2 are further stirred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com