BUCK converter bootstrap drive circuit based on narrow pulse control

A bootstrap drive circuit and drive circuit technology, which are used in control/regulation systems, output power conversion devices, conversion of DC power input to DC power output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A detailed description will be given below in conjunction with the accompanying drawings.

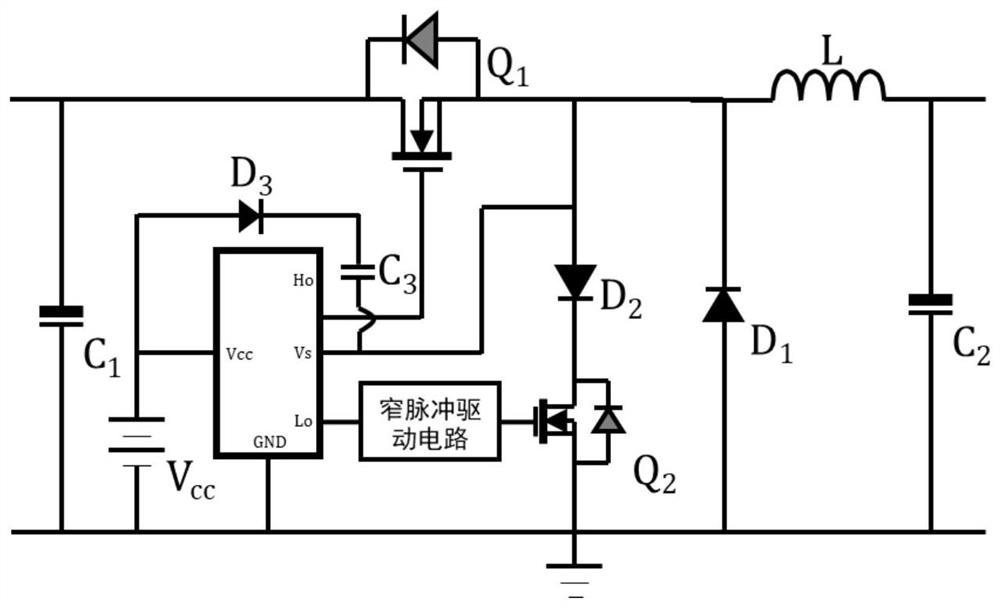

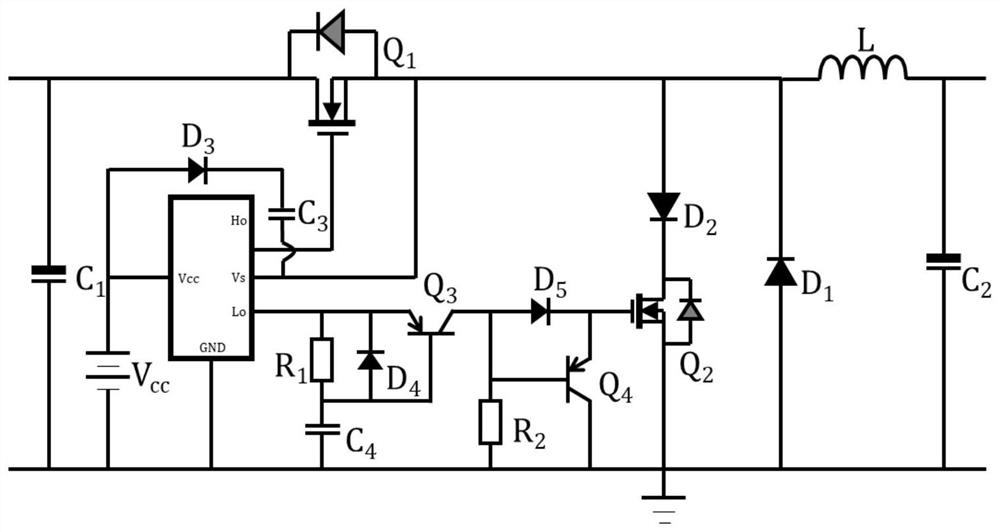

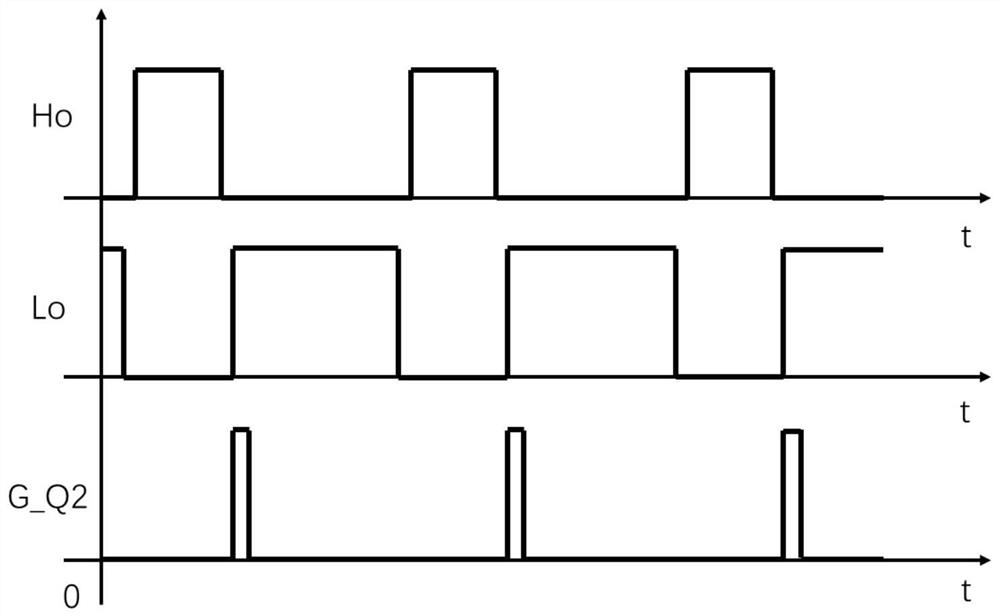

[0031] Preferably, the technical problems of the present invention are described in detail. For the synchronous rectification type BUCK converter bootstrap drive circuit, when the BUCK circuit is in a light-load / no-load state, the energy storage inductor L will enter the current discontinuous working mode. At this time the output filter capacitor C 2 Discharging through the energy storage inductor L and the added bootstrap charging circuit will generate a large negative current, which will cause additional loss. At the same time, if the negative current is overloaded, the added MOS tube (such as the secondary switch tube Q 2 ) and diodes need to use high-current MOS tubes and diodes, which increases the cost of the device. Specifically, as figure 1 , Figure 4 and Figure 5 As shown, when the BUCK circuit is in the light-load / no-load state, the current may cross zero. In s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com