Automatic focusing system for laser manufacturing

An automatic focusing and laser technology, applied in optics, optical components, microscopes, etc., can solve the problems of difficult to observe focusing, the automatic focusing detector does not provide a movable bracket, and the system structure is complex, achieving a wide range of applications and low cost. , the effect of high motion precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

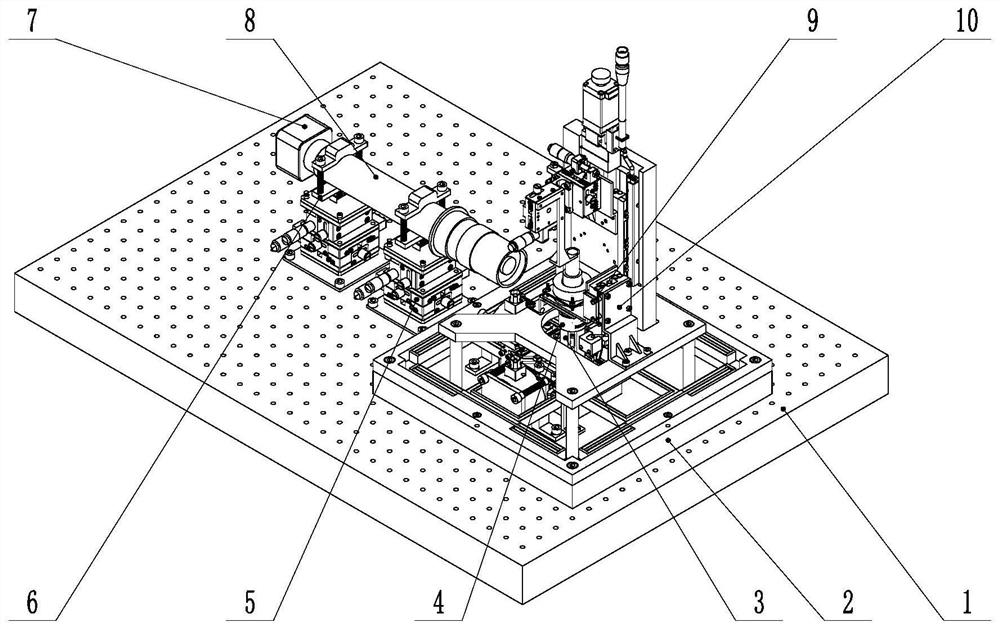

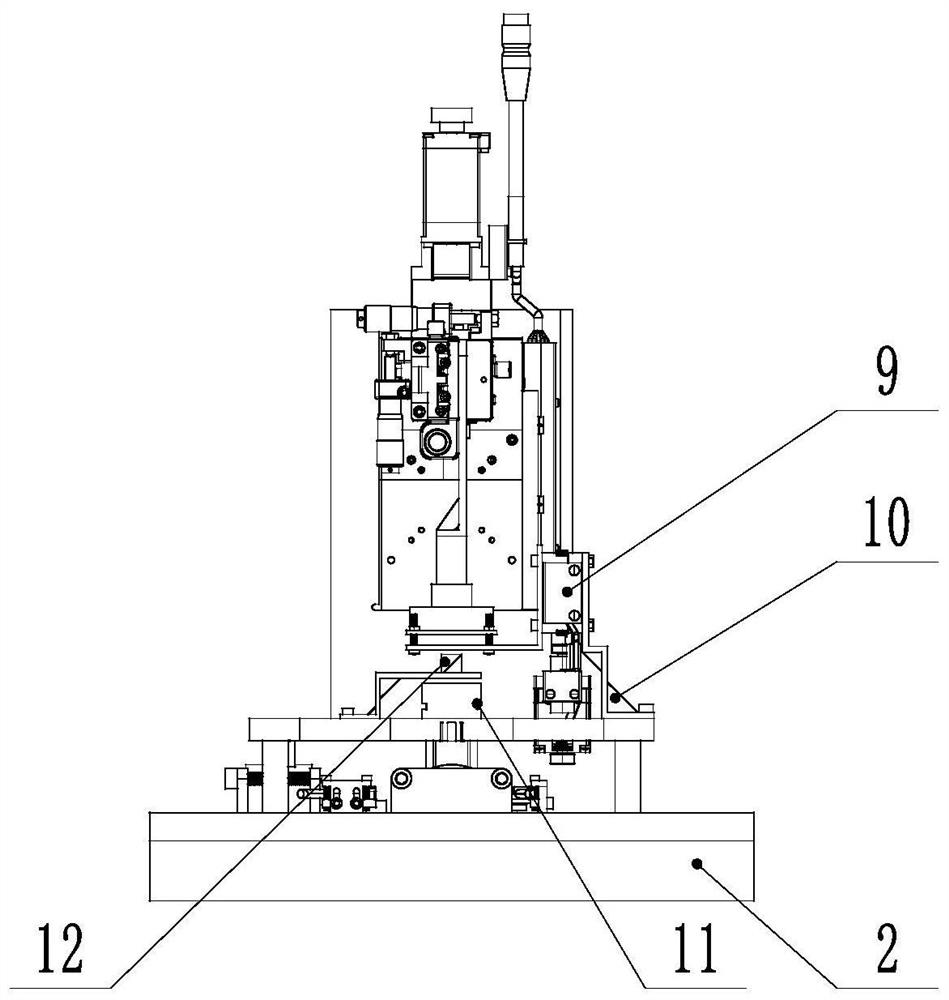

[0035] The invention provides an automatic focusing system for laser manufacturing, which includes an installation platform, an optical module, an image acquisition module, a precision position adjustment module, an image processing module, a communication module and a motion control module.

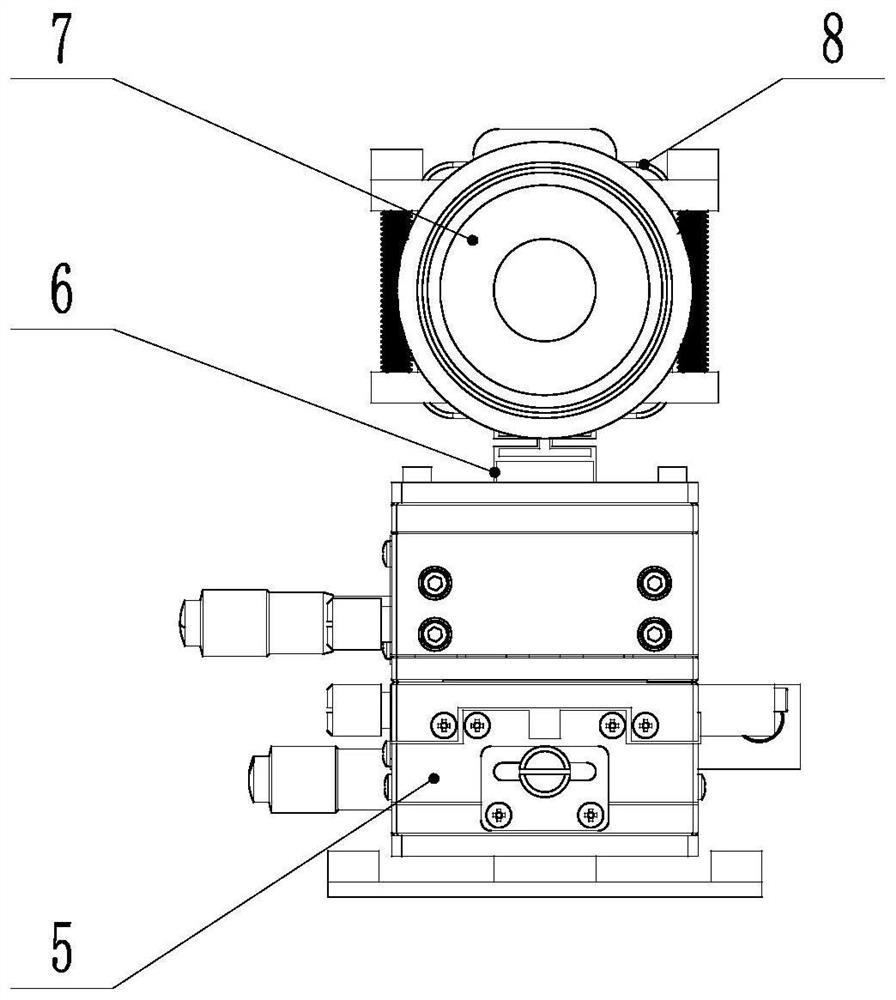

[0036] The image acquisition system collects the spot image of the laser on the processing surface, processes it through the image processing module, and completes the laser automatic focusing through the motion control module. The precise position adjustment module can fine-tune the position of the image acquisition module to facilitate capturing the spot in the field of view; through the reasonable design of the optical module, the automatic focus and real-time monitoring of the laser spot can be realized while the processing is in progress.

[0037] The installation platform includes a base 1 and a motion platform 2; the optical module includes a laser light source 3, a lens 11, a beam...

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1. For the sake of brevity, in the description process of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0055] Further, the image processing algorithm may be an image processing algorithm based on the minimum circumscribed circle of the light spot. The specific process of the algorithm is as follows:

[0056] Firstly, the image is collected, the image is processed in grayscale, and the grayscale image is binarized according to the preset threshold. In order to eliminate the influence of image noise, median filtering is performed. In this embodiment, a 3×3 filtering window is selected. In the processed image, the pixels at the spot are white, and the rest are black. Use the minimum circumscribed circle to envelop all white pixel values. In order to avoid collecting small spots when they are not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com