Frequency multiplication differential anti-interference mirror reflection orthogonal imaging circumferential weld detection device and method

A specular reflection and detection device technology, which is applied in the direction of measuring devices, analyzing materials, optical testing flaws/defects, etc., to ensure the consistency of imaging, improve the recognition rate, and overcome the effect of large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

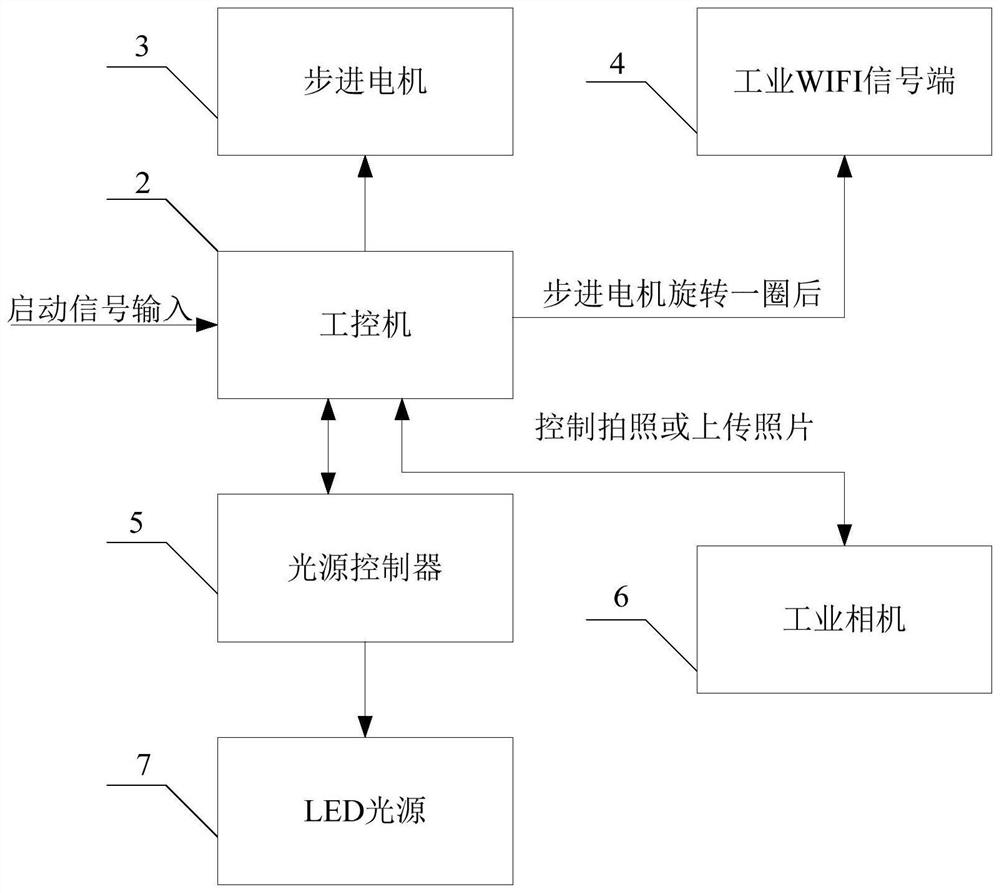

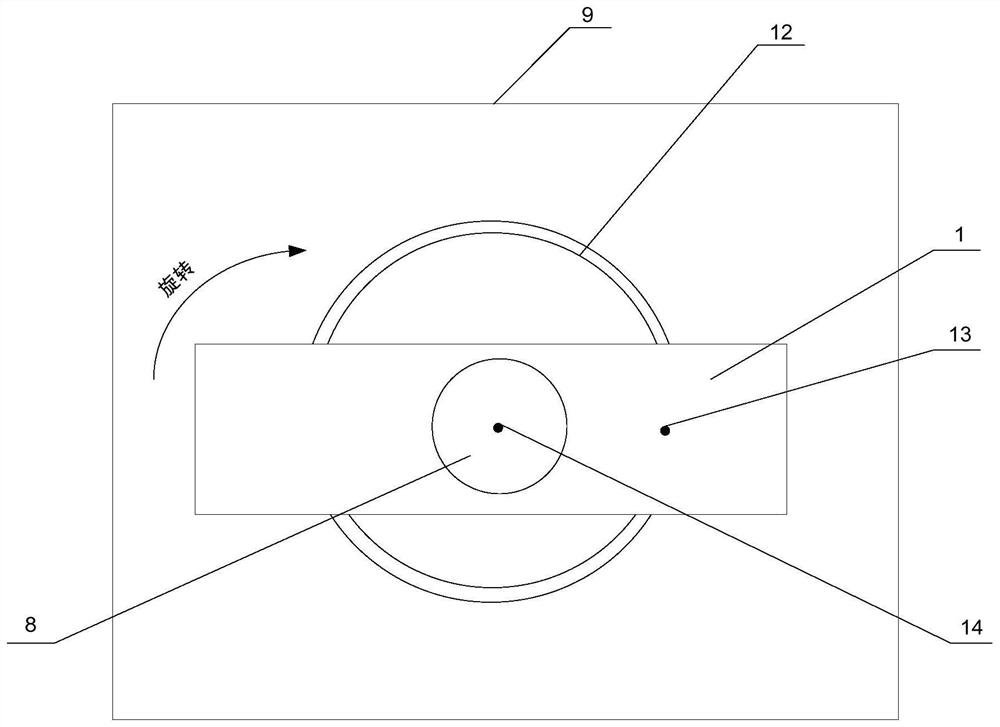

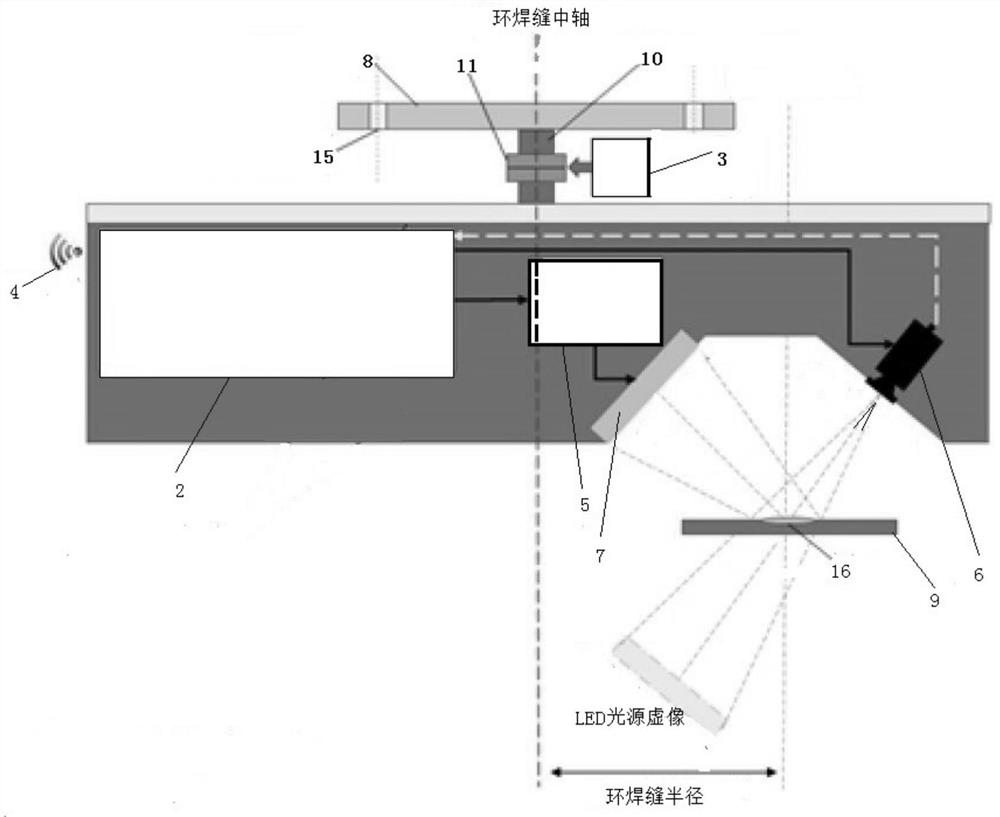

[0042] Such as figure 1 As shown, the present invention provides a girth weld detection device for frequency multiplication differential anti-interference mirror reflection orthogonal imaging, including a support rotation mechanism 1, an industrial computer 2, a stepping motor 3 connected to the industrial computer 2, and an industrial WIFI The signal terminal 4, the light source controller 5 and the industrial camera 6, the LED light source 7 connected to the light source controller 5 and the installation top plate 8 positioned above the supporting rotating mechanism 1, the industrial computer 2, the industrial WIFI signal terminal 4, The light source controller 5 , the industrial camera 6 and the LED light source 7 are all arranged on the support rotation mechanism 1 . The installation top plate 8 is located above the girth weld detection object 9 and a rotating bearing 10 is provided between the supporting rotating mechanism 1 and the installation top plate 8 . The rotating...

Embodiment 2

[0050] Such as Figure 6 As shown, the present invention provides a girth weld detection method of frequency multiplication differential anti-interference mirror reflection orthogonal imaging, and its implementation method is as follows:

[0051] S1, input start signal;

[0052] S2. According to the starting signal, control the light source controller through the industrial computer to drive the LED light source, and use the frequency multiplication differential imaging sequence to modulate the intensity of the LED light source with frequency f. The implementation method is as follows:

[0053] S201. According to the start signal, control the light source controller to drive the LED light source through the industrial computer;

[0054] S202. Set the output timing of the LED light source as a square wave with a modulation frequency f by using the frequency multiplication differential imaging timing;

[0055] S203. Using a square wave with a modulation frequency f to modulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com