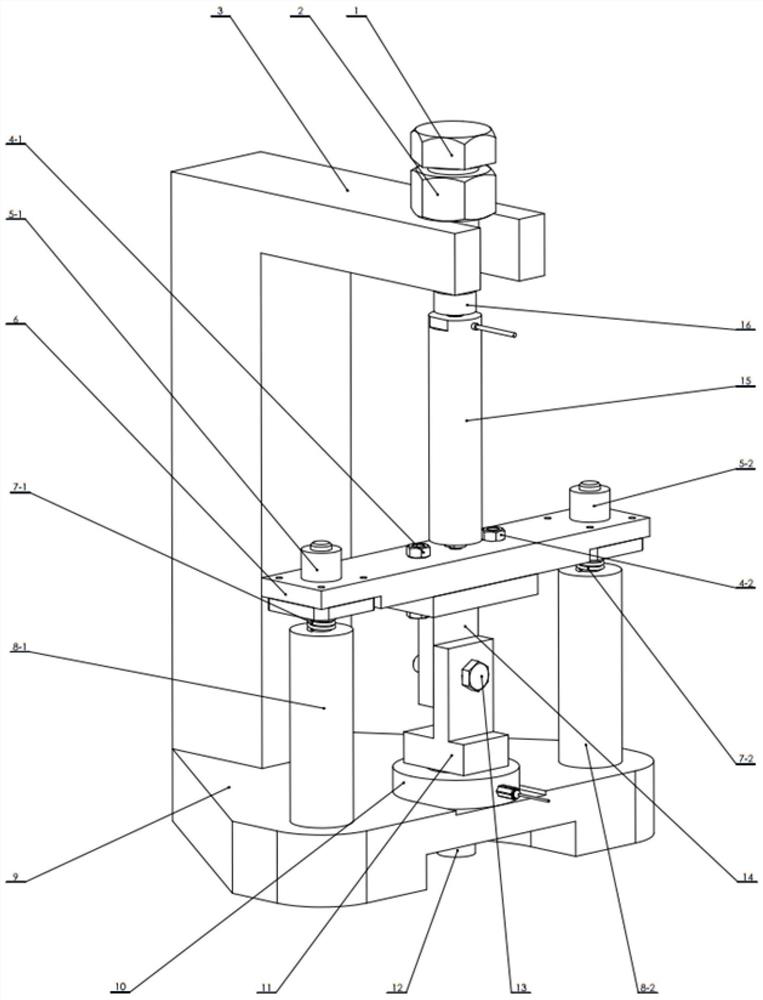

A device for testing the tangential stiffness of the contact interface under cyclic loading based on piezoelectric actuators

A technology of piezoelectric actuators and contact interfaces, applied in the testing of machines/structural components, measuring devices, testing of elasticity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

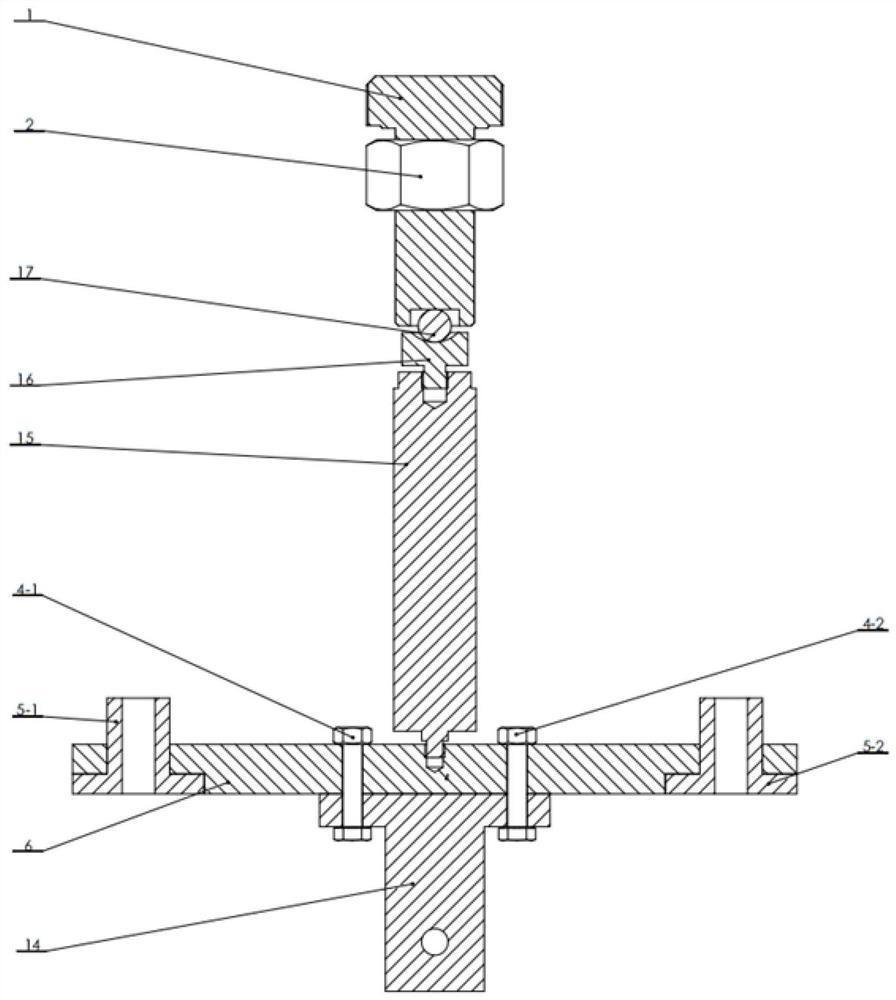

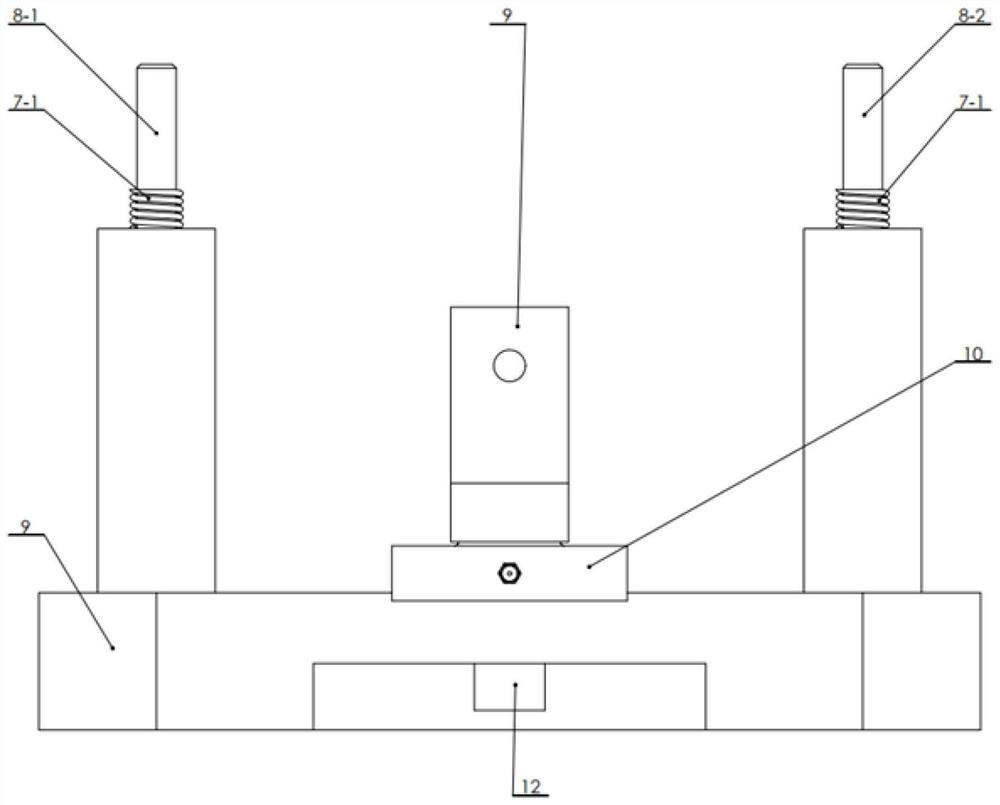

[0023] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0024] Application of cyclic load on the actuating part:

[0025] The upper and lower ends of the piezoelectric actuator 15 are respectively connected to the adapter 16 and the movable horizontal plate 6 through threads. The upper end surface of the adapter 16 is processed with arc grooves, and the lower end surface of the top tightening bolt 1 is processed with blind holes. When the bolt 1 is tightened, the steel ball 17 is clamped between the tightening bolt 1 and the adapter 16. At this time, the upper end of the piezoelectric actuator 15 is pushed to death. When a voltage is input to it, the piezoelectric actuator 15 The lower end of the lower end will hit the corresponding force downwards to hit the movable horizontal plate 6 and the movable test piece 14. The linear bearings 5 at both ends are set o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com