Ice-resistant cone for offshore structure and operation process of ice-resistant cone

An offshore structure and anti-ice cone technology, which is applied in the direction of basic structure engineering, underwater structures, artificial islands, etc., can solve the crushing damage of ice sheets, reduce the ability of cone structures to reduce ice loads, and do not have sea ice data Acquisition and sea ice warning and other issues, to achieve the effect of prolonging the service life, simple and practical method, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

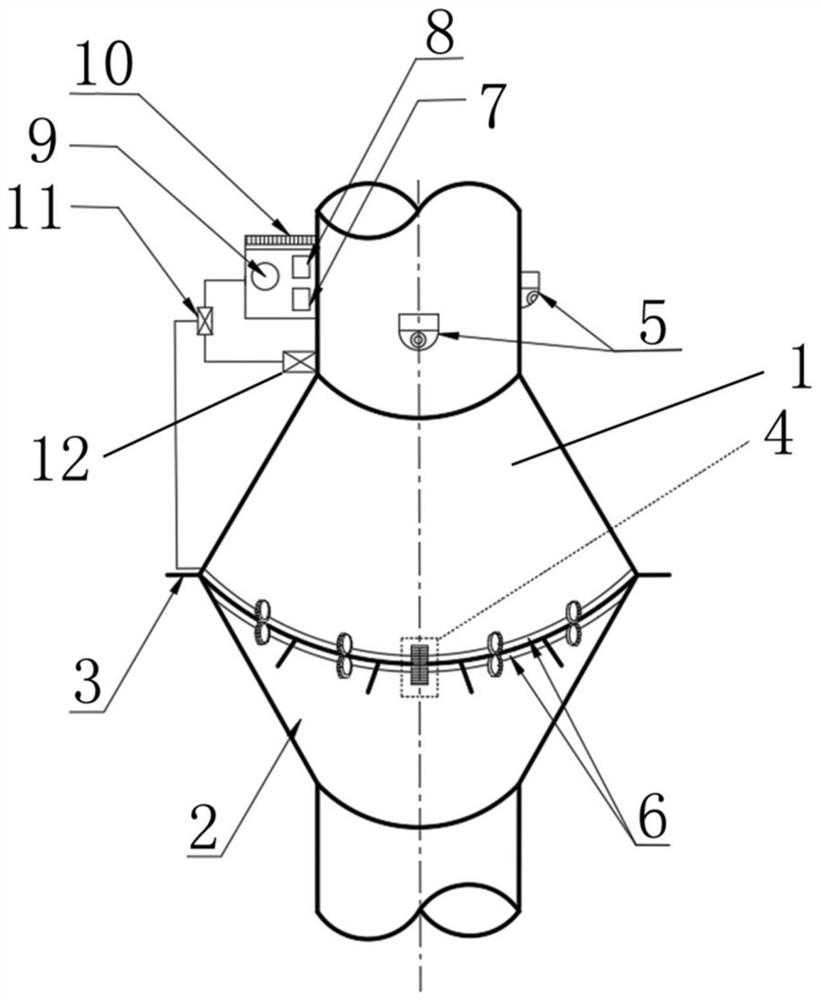

[0047] An anti-ice cone for offshore structures such as figure 1 As shown, it includes a main body, an ice breaking device, an infrared smart high-speed ball 5 , a pressure sensing belt 6 , a monitoring module, a control device 11 and a computing module 12 .

[0048] The main body is two conical structures with equal bottom diameters. The bottom of the conical structures is a cone, and the top is a cylinder. Cone 2, the front cone 1 and the bottom surface of the inverted cone 2 are mated, and the cone angles of the vertebral bodies of the forward cone 1 and the inverted cone 2 are both 50°-65°.

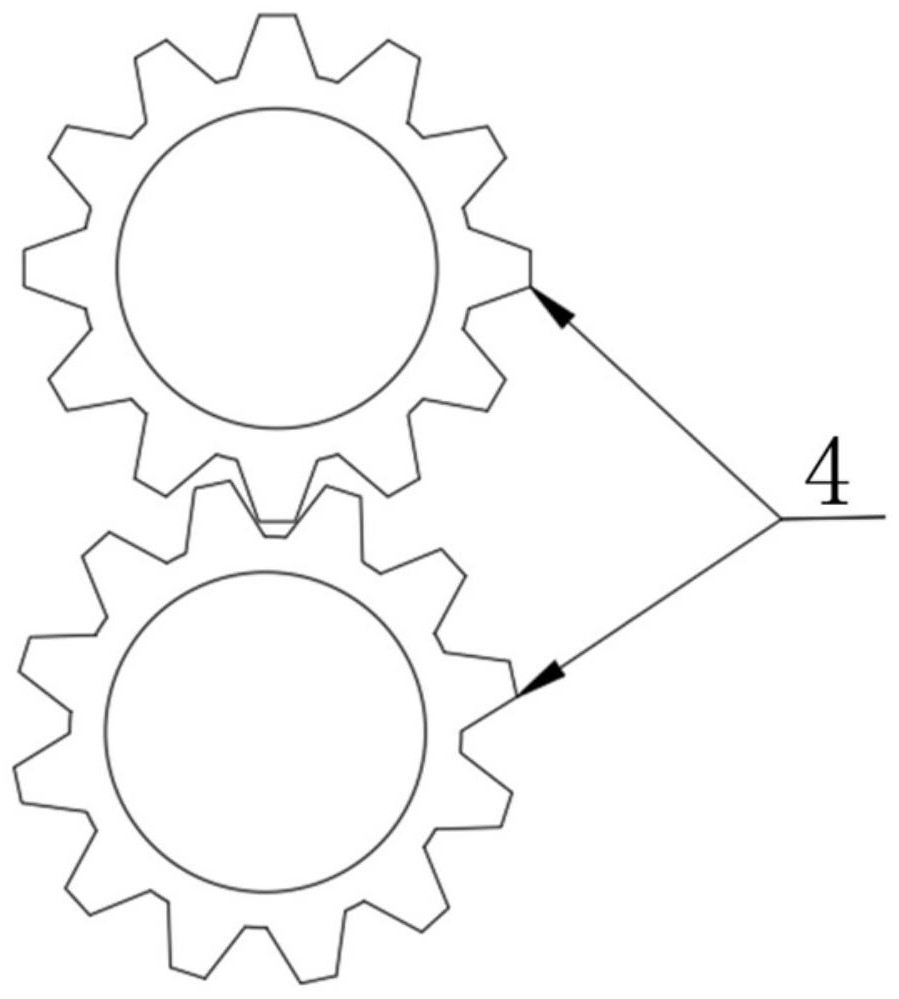

[0049] The ice breaking device includes a horizontal blade 3 and a vertically rotating gear 4, and the horizontal blade 3 and the vertically rotating gear 4 are arranged at intervals outside the junction of the forward cone 1 and the inverted cone 2; as figure 2 As shown, the vertically rotating gear 4 is in the form of two gears biting each other, and the friction between the gears...

Embodiment 2

[0055] A kind of anti-icicle operation process for offshore structures, the specific steps are as follows:

[0056] (1) When it is found that the floating ice is close to the foundation of the offshore structure and the height of the ice layer is at the junction height of the forward and reverse cones, turn the horizontal blade and the vertically rotating gear to make the floating ice break from the middle and bend upward or downward, so as to achieve The purpose of reducing the ice load on the foundation.

[0057] (2) When the radar system detects the formation of floating ice within 1km, the infrared smart high-speed dome starts to work to monitor the sea surface in real time. When it recognizes a large area of floating ice (generally ice floating with a horizontal scale greater than 20m) When starting to approach, the calculation module starts to work while automatically tracking the ice floe. The infrared smart high-speed ball records the actual moving distance L of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com