Device for preparing Topcon battery passivation film layers and technological process thereof

A passivation film and battery technology, applied in metal material coating technology, sustainable manufacturing/processing, coating, etc., can solve the problems affecting the quality of the film layer, affecting the takt time, reducing production capacity, etc., to improve the coating rate, The effect of improving uniformity and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

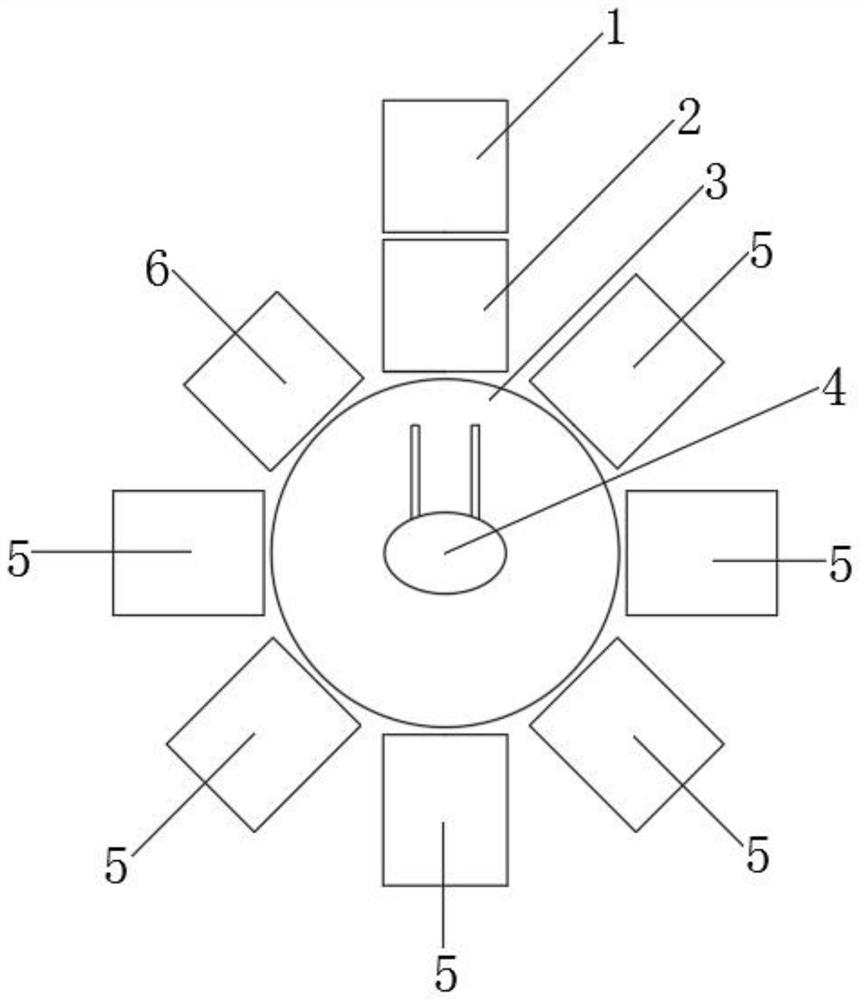

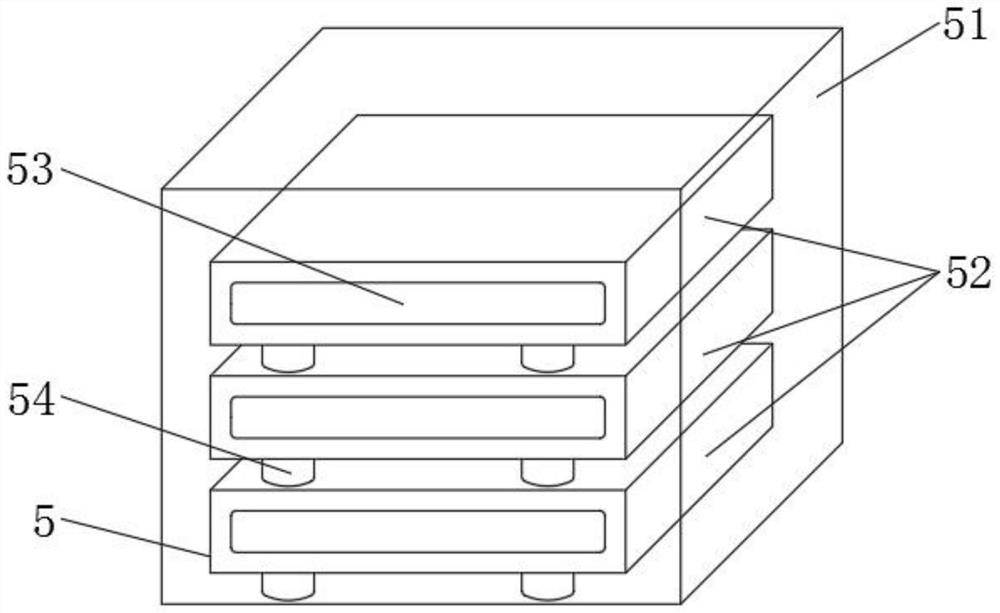

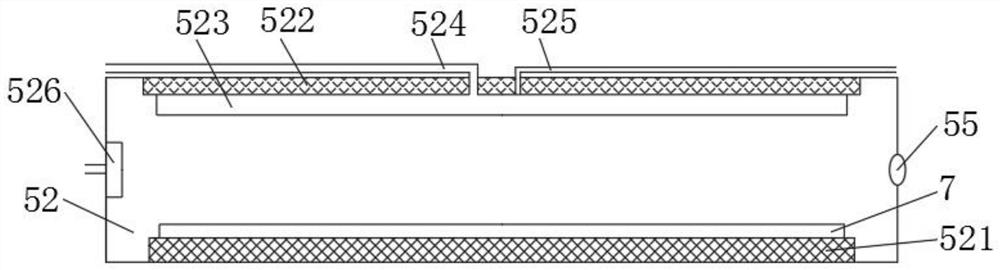

[0041] In this implementation, the coating methods of the coating chamber 52 are plate ALD and PECVD, and a plurality of the coating modules 5 are arranged in a circumferential direction with the vacuum transmission chamber 3 as the center of the circle, and four coating modules 5 ( figure 1 There are six coating modules 5) to carry out synchronous coating operation, each coating module 5 adopts the structure of three laminated coating chambers 52 (also can be more laminated coating chambers 52), three described coating chambers 52 are stacked and arranged sequentially from bottom to top, each coating chamber 52 is an independent vacuum coating chamber, and the three coating chambers 52 are placed in an outer vacuum chamber 51 to realize an inner double vacuum chamber structure. Among them, the two coating modules 5 are for preparing ultra-thin silicon dioxide film layers, and the other two coating modules 5 are for preparing doped amorphous and microcrystalline silicon film la...

Embodiment 2

[0050] In this implementation, the coating methods of the coating chamber 52 are plate type PEALD and PECVD, and a plurality of the coating modules 5 are arranged in a circumferential direction with the vacuum transmission chamber 3 as the center of the circle, and four coating modules 5 ( figure 1 There are six coating modules 5) to carry out synchronous coating operation, each coating module 5 adopts the structure of three laminated coating chambers 52 (also can be more laminated coating chambers 52), three described coating chambers 52 are stacked and arranged sequentially from bottom to top, each coating chamber 52 is an independent vacuum coating chamber, and the three coating chambers 52 are placed in an outer vacuum chamber 51 to realize an inner double vacuum chamber structure. Among them, the two coating modules 5 are for preparing ultra-thin silicon dioxide film layers, and the other two coating modules 5 are for preparing doped amorphous and microcrystalline silicon ...

Embodiment 3

[0059] Different from Embodiment 1 and Embodiment 2, this embodiment adopts UV dissociation method to prepare silicon dioxide layer. In step 3) of the process flow of the device for preparing the Topcon battery passivation film layer, the preheated silicon wafer And the tray 7 is sent to the heating plate 521 in the coating chamber 52 of the coating module 5 of the two coating modules 5 preparing the silicon dioxide film layer by the manipulator 4, and the valve 53 is closed; at first, the oxygen of 500-5000 sccm is passed into, and ozone is generated by UV. Make it oxidize with the silicon atoms on the surface of the silicon wafer to form a silicon dioxide film layer. The continuous introduction of oxygen makes the silicon dioxide film layer formed by oxidation on the surface of the silicon wafer continuously thicken. After 10-120s, the silicon dioxide film layer is completed. Preparation of the silicon dioxide film layer of the wafer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com