Device for manufacturing data acquisition wire bundle

A technology for data acquisition and wire bundling, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

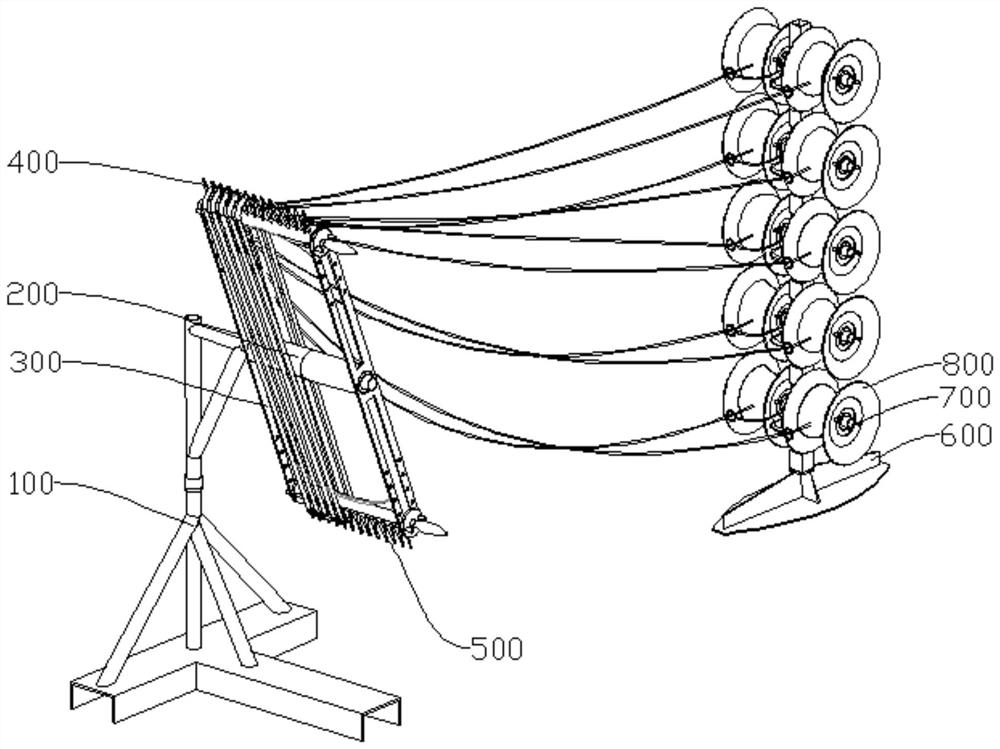

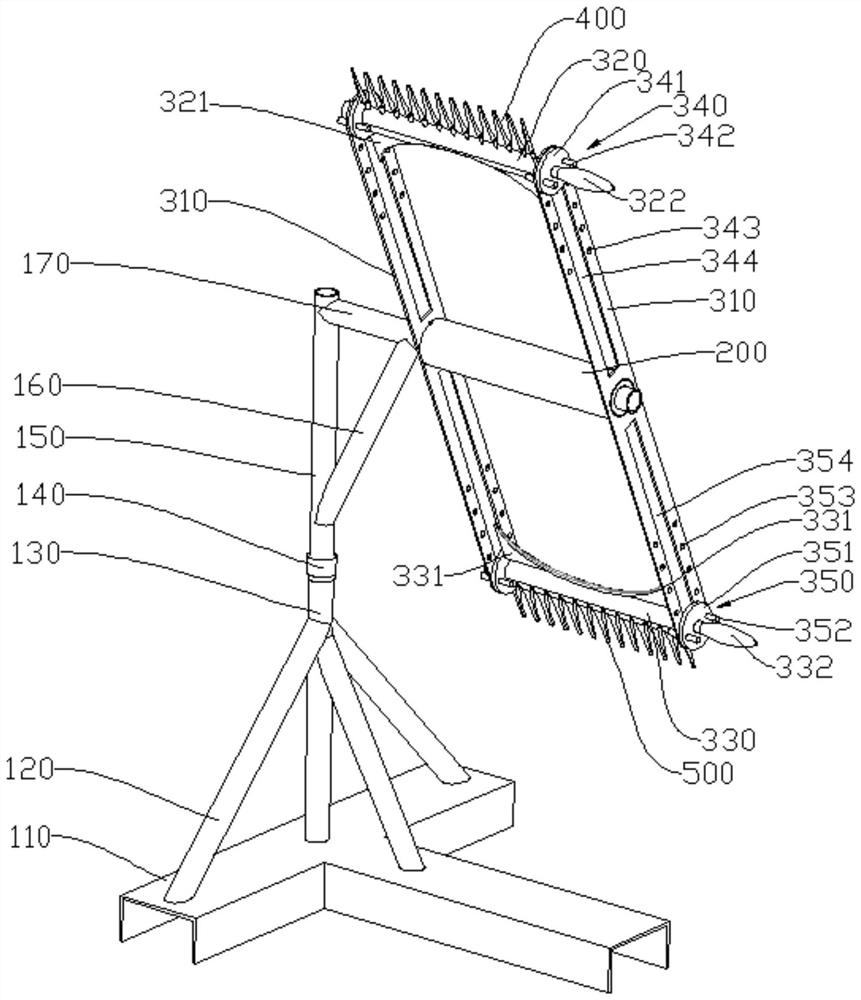

[0023] Such as figure 1 As shown, the present invention mainly includes a spinning frame 300 for spinning, the middle part of the spinning frame 300 is detachably connected to the drum 200 through a connector, and the drum 200 is rotatably connected to the spinning base that supports the spinning frame 100 on.

[0024] Such as figure 1 As shown, the upper end of the spinning frame 300 is provided with a plurality of upper spinning comb bars 400 arranged side by side, and the lower end of the spinning frame 300 is provided with a plurality of lower spinning comb bars 500 arranged side by side. The comb tooth bar 400 and a plurality of lower spinning comb tooth bars 500 are arranged in a one-to-one correspondence.

[0025] Such as figure 2 In the illustrated embodiment, the supporting base 100 includes a horizontally arranged fixed base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com