Yarn suction device, full-automatic yarn twisting instrument and working method of twisting instrument

A fully automatic, yarn technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of yarn winding and knotting, and achieve the effect of improving efficiency, solving yarn winding and knotting, and improving yarn arrangement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

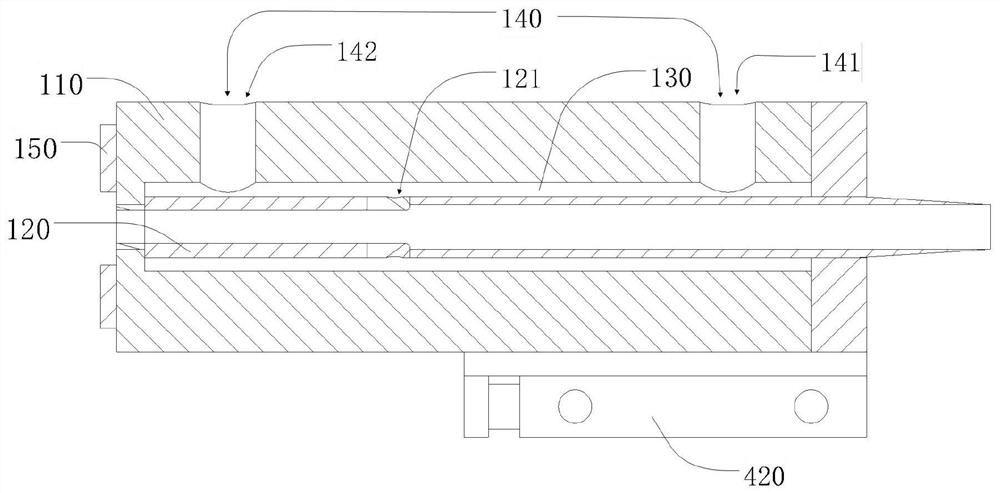

[0031] Such as figure 1 As shown, the present invention provides a yarn suction device which may include: gun body 110; yarn suction tube 120, which is arranged inside gun body 110 and runs through both ends of gun body 110; gas channel 130, which is opened inside gun body 110 and is located Periphery of yarn bobbin 120; air vent 121, which communicates gas channel 130 with yarn suction tube 120, and the inclination direction of air vent 121 faces the yarn output direction of yarn suction tube 120; and suction air inlet 140, opened on gun body 110 And communicate with the gas channel 130; after any suction air inlet 140 enters the air, the gas enters the yarn suction tube 120 through the gas channel 130 through the air port 121 and sprays toward the yarn output direction, so that the yarn suction tube located at the rear side of the air port 121 Negative pressure is generated in the space of 120 to suck the yarn from the front end of the yarn suction tube 120.

[0032] In thi...

Embodiment 2

[0036] On the basis of Embodiment 1, in this embodiment, the yarn suction device may only include one suction air inlet 140, and the air source 500 may pass a large flow of gas or a small flow of gas to the suction air inlet 140. When a large flow of gas is used, a negative pressure is generated in the space of the yarn suction tube 120 at the rear side of the vent 121 to discharge the yarn; Negative pressure for yarn straightening.

Embodiment 3

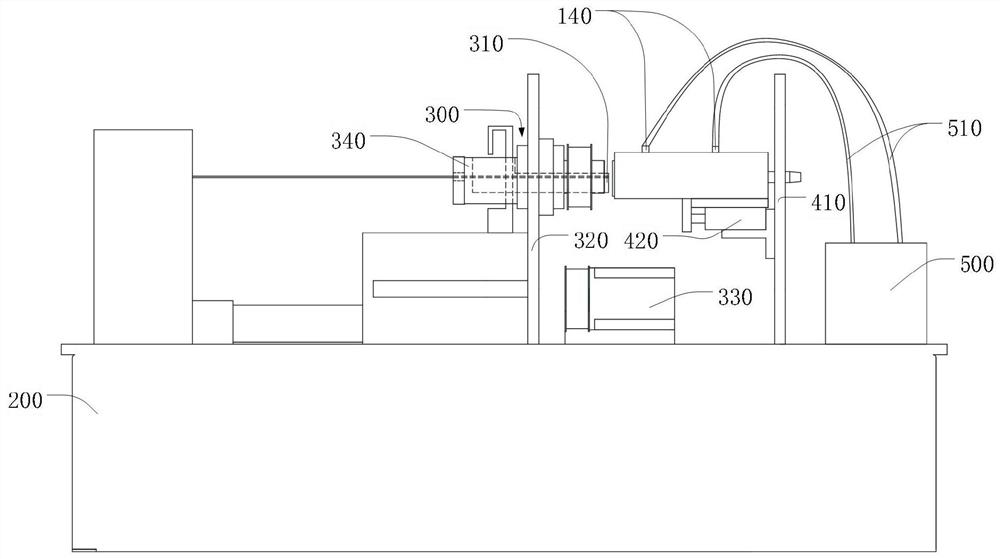

[0038] Such as figure 2 As shown, on the basis of the above-mentioned embodiments, the present invention also provides a fully automatic yarn twist meter, comprising: a rotary clamping mechanism 300, the tail end of which is provided with a yarn outlet 310 for yarn discharge; the above-mentioned yarn suction device , after docking with the rotary yarn clamping mechanism 300, it sucks and discharges the yarn from the yarn outlet 310 for yarn discharge by generating negative pressure; in this embodiment, the base 200 is provided with first brackets 410 with appropriate spacing and the second bracket 320; the yarn suction device is fixed on the first bracket 410 by one end of the push-pull device 420, and the yarn suction tube 120 passes through the first bracket 410; the rotary clamping mechanism 300 is arranged on the second bracket 320 and the yarn outlet 310 for yarn discharge is aligned with the yarn suction tube 120.

[0039] Further, the rotary clamping mechanism 300 inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com