An optical fiber sponge reel wrapping and packaging production line

A packaging production line and optical fiber reel technology, which is applied in the field of optical fiber sponge reel wrapping and packaging production lines, can solve the problems of low work efficiency and uneven quality, and achieve the effects of reducing labor intensity, improving friction, and improving structural stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

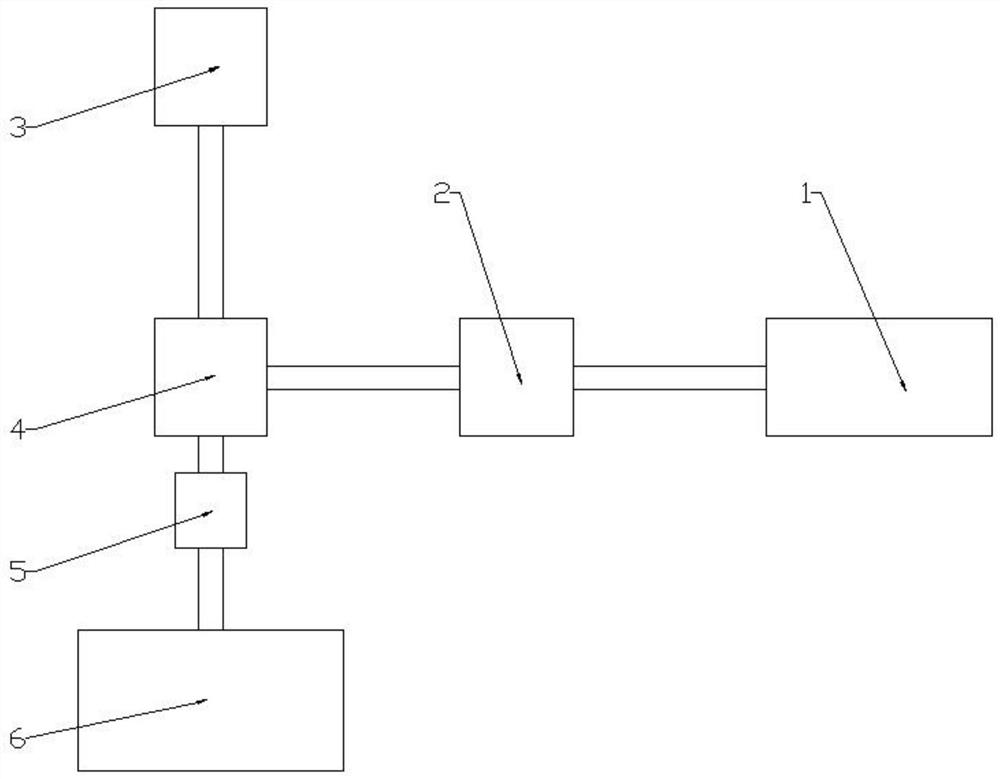

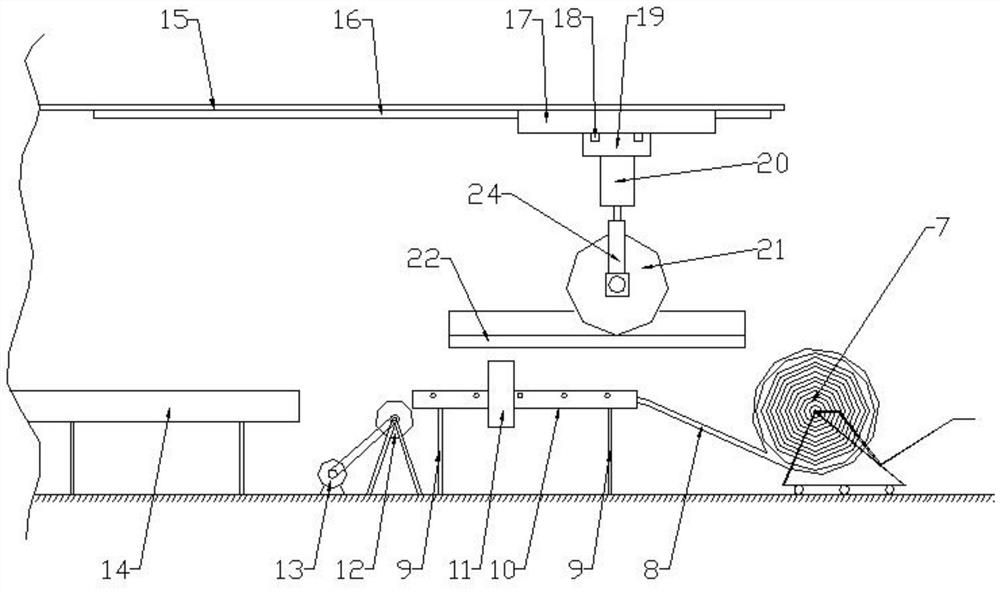

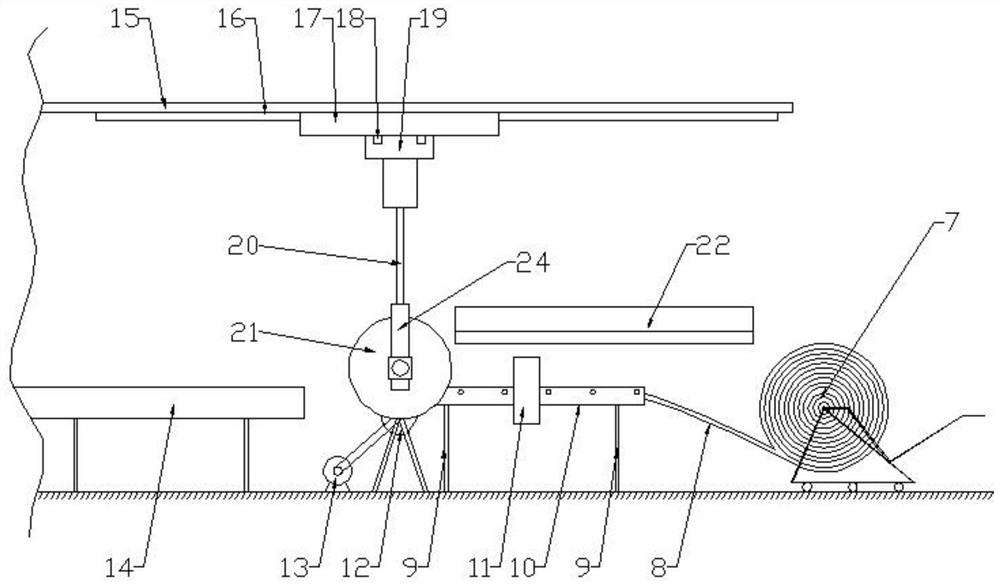

[0039] Such as Figure 1 to Figure 4 As shown, an optical fiber sponge reel wrapping and packaging production line includes a control system and a sponge winding device 1 equipped with the control system, a side sealing heat shrink packaging machine 2, an automatic unpacking machine 3, a high-speed manipulator 4, a sealing The box machine 5 and the bin 6 with the stacking robot inside; the sponge winding device 1 specifically includes a sponge feeding device, a sponge cutting device 11, an optical fiber disc moving device, a viscose smearing plate and a sponge winding mechanism; the sponge feeding device The device consists of a first bracket 9 and a sponge delivery tank 10 placed on the top of the first bracket 9. Several feeding pressure rollers are arranged on the notch of the delivery groove 10, and several smooth protrusions are arranged on the surface of the feeding pressure rollers. The roller and the sponge conveying tank 10 are in a vertical relationship, and the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com