Test tube rotating mechanism and test tube rotating code-scanning device

A rotating mechanism and test tube technology, applied in the field of medical equipment, can solve the problems that the motor cannot drive the sample to rotate, and the noise is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

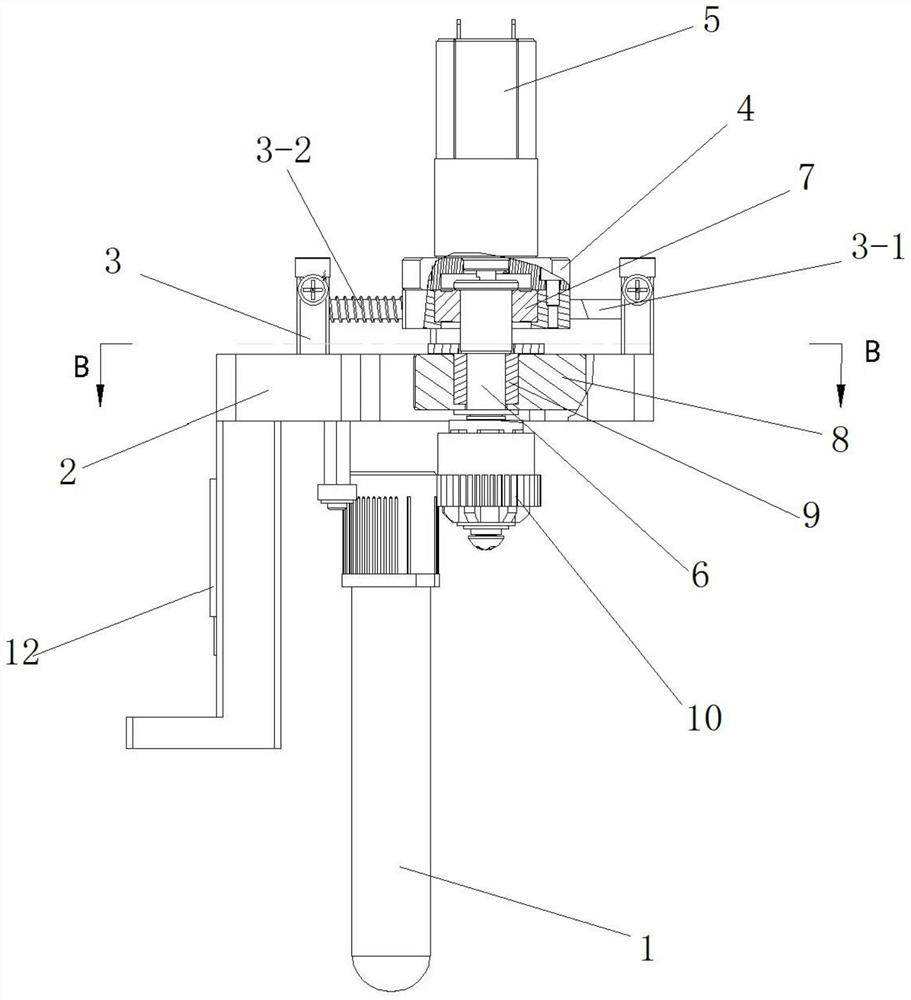

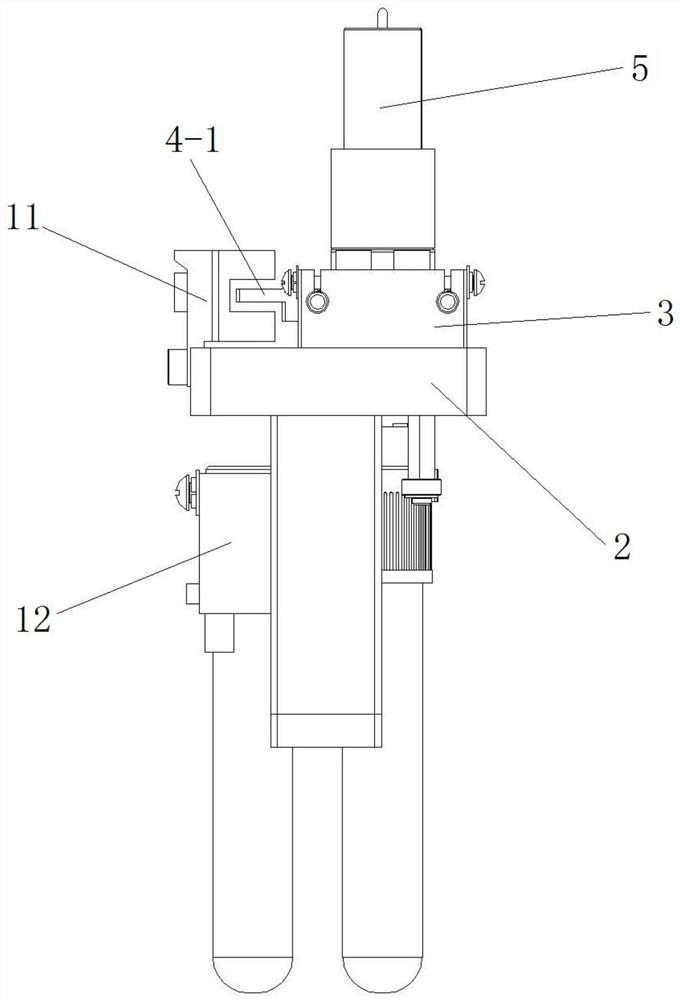

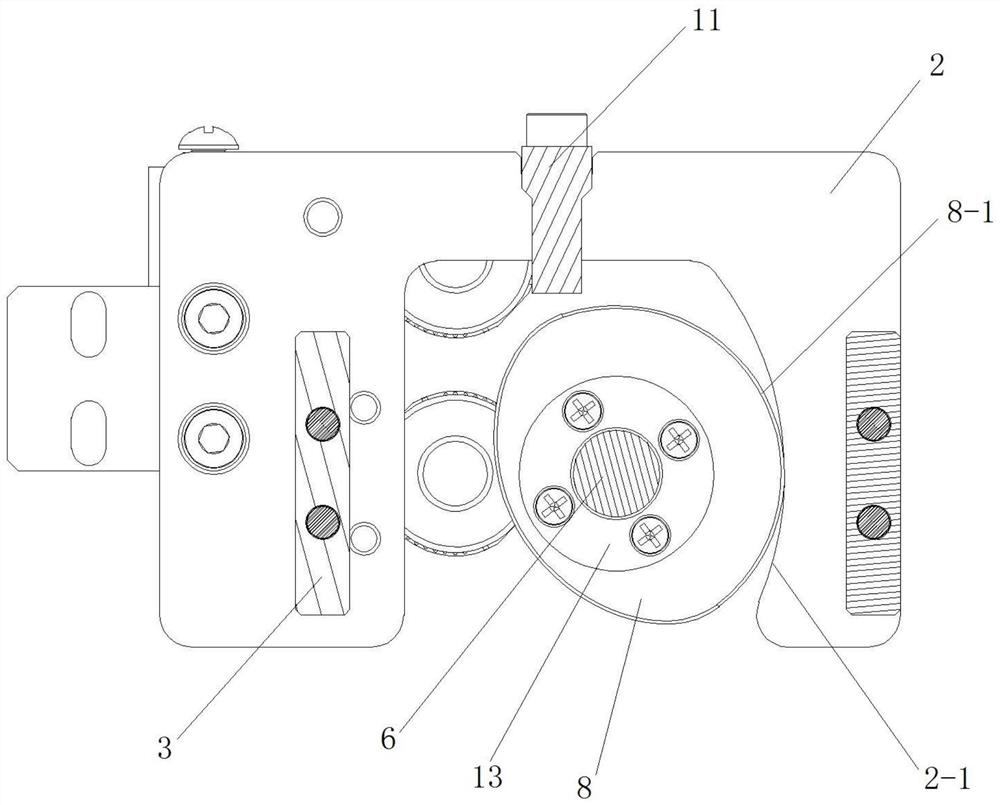

[0021] For a better understanding of the application, various aspects of the application will be described in more detail with reference to the accompanying drawings. It should be understood that these detailed descriptions are descriptions of exemplary embodiments of the application only, and are not intended to limit the scope of the application in any way. Throughout the specification, the same reference numerals refer to the same elements.

[0022] In the drawings, the thickness, size and shape of objects have been slightly exaggerated for convenience of illustration. The drawings are examples only and are not strictly drawn to scale.

[0023] It should also be understood that the terms "comprising", "having", "comprising" and "comprising", when used in this specification, mean that the features, integers, steps, operations, elements and / or components exist, But it does not exclude the presence or addition of one or more other features, entities, steps, operations, eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com