Pneumatic positioning and locking pin hook mechanism.

A positioning locking and bolt locking technology, which is applied in the direction of auxiliary devices, coatings, auxiliary welding equipment, etc., can solve the problems of difficult recovery of mold precision, difficult quality control, difficult debugging, etc., and achieves small footprint and simple structure , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

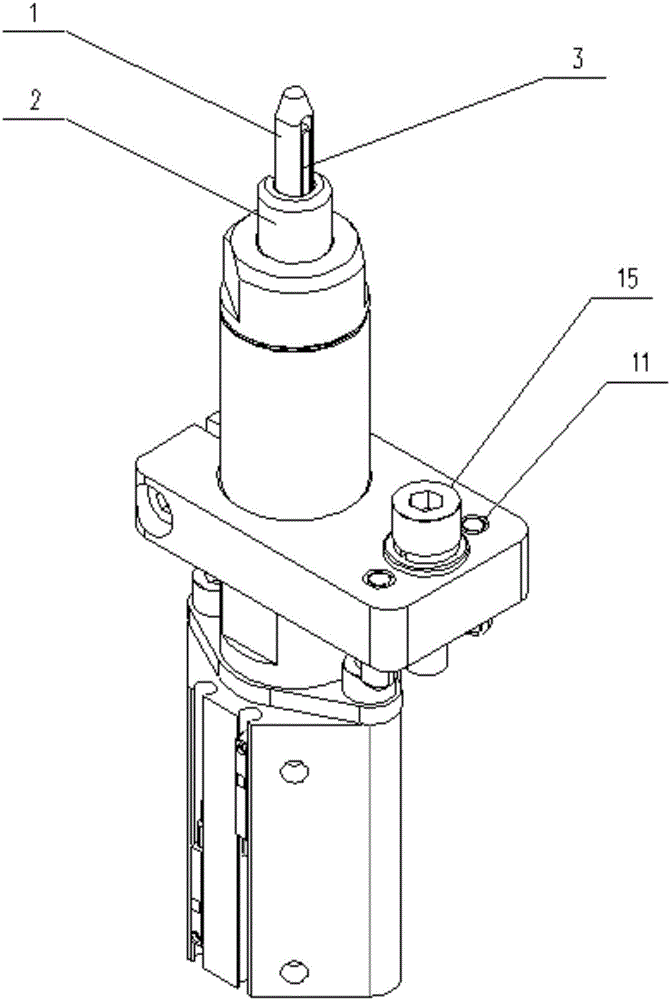

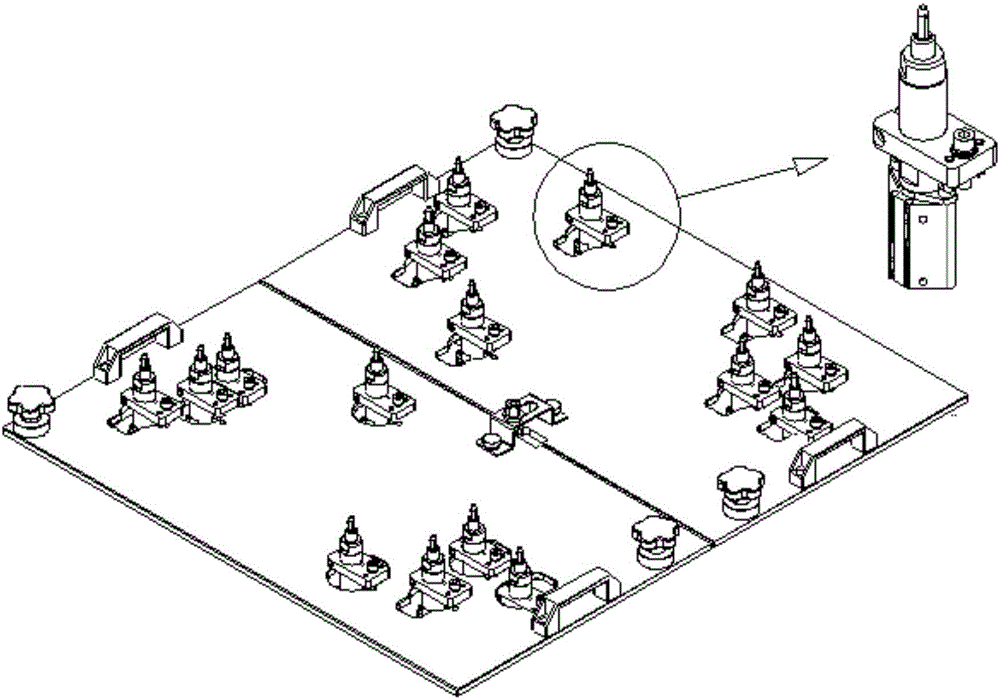

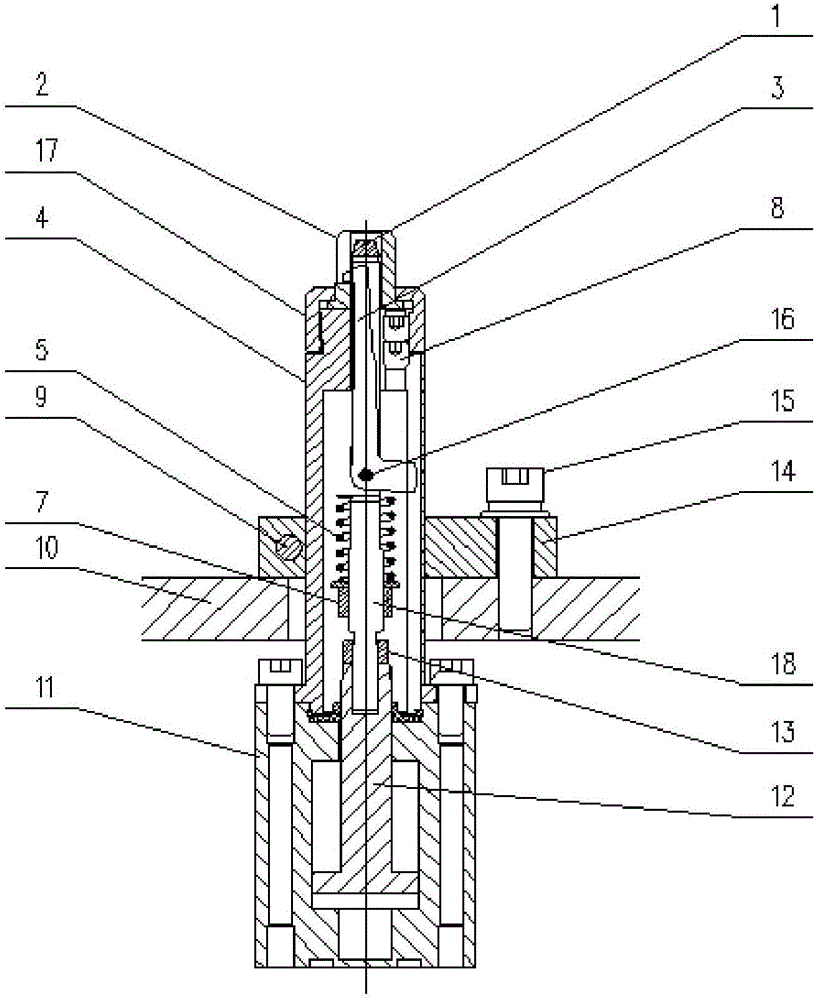

[0026] The mechanism includes: pin 1, support ring 2, hook 3, pin body 4, spring 5, spring preload nut 7, top wire 8, pin body locking bolt 9, mold mounting plate 10, cylinder 11, cylinder rod 12 , pin lock nut 13, pin body fixing plate 14, pin body fixing plate bolt 15, cylindrical pin 16, support ring gland 17, connecting rod 18;

[0027] The hook 3 is Z-shaped as a whole;

[0028] The middle part of the pin 1 has a long slot, and the "Z" hook 3 can be hidden in it; the upper part of the support ring 2 is slotted on one side, and it is aligned with the slot of the pin 1 during installation; the pin 1 and the support ring 2 are used as parts to be processed. The positioning of the component 6, the upper part of the hook 3 can extend out of the pin 1 groove from the side, and is used to lock the component 6 to be processed;

[0029] The support ring gland 17 is threadedly connected with the pin body 4, and the support ring 2 and the pin body 4 are installed together;

[0030...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com