Photolithography equipment and detection method of pupil surface transmittance of lithography equipment

A lithography equipment and transmittance technology, applied in the field of image sensors, can solve problems such as long detection time, and achieve the effects of short detection time, guaranteed imaging contrast, and convenient detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

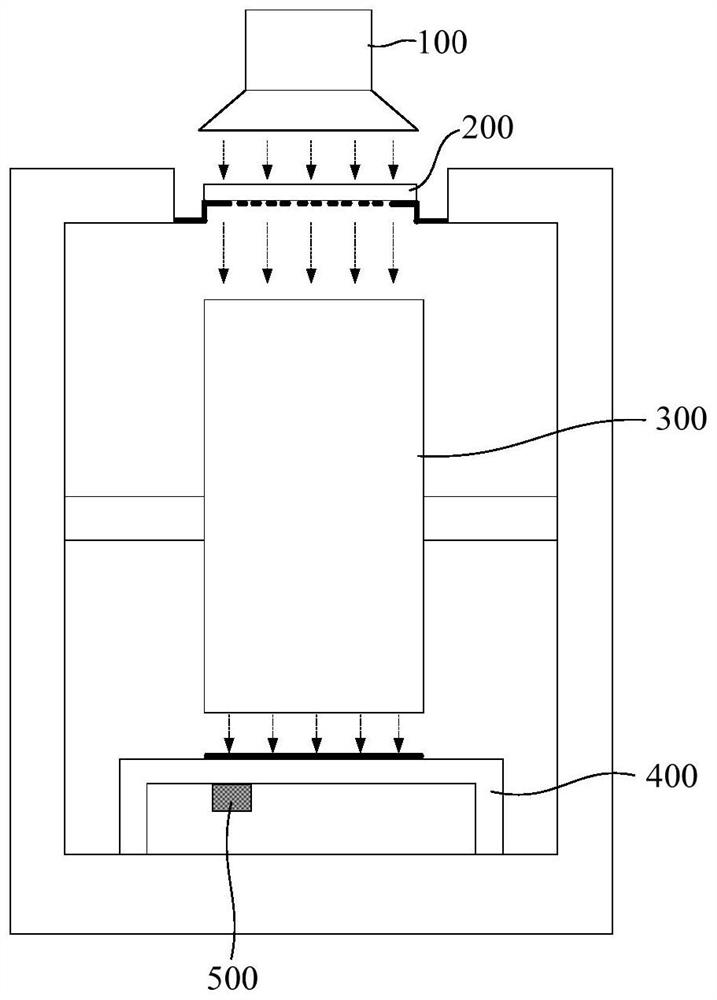

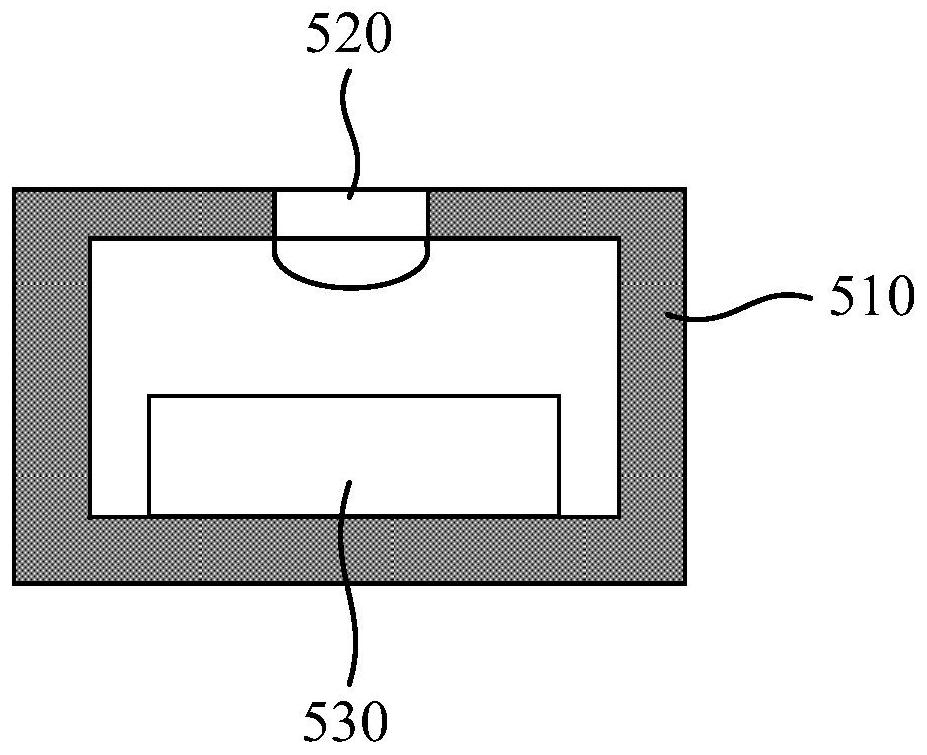

Image

Examples

Embodiment 2

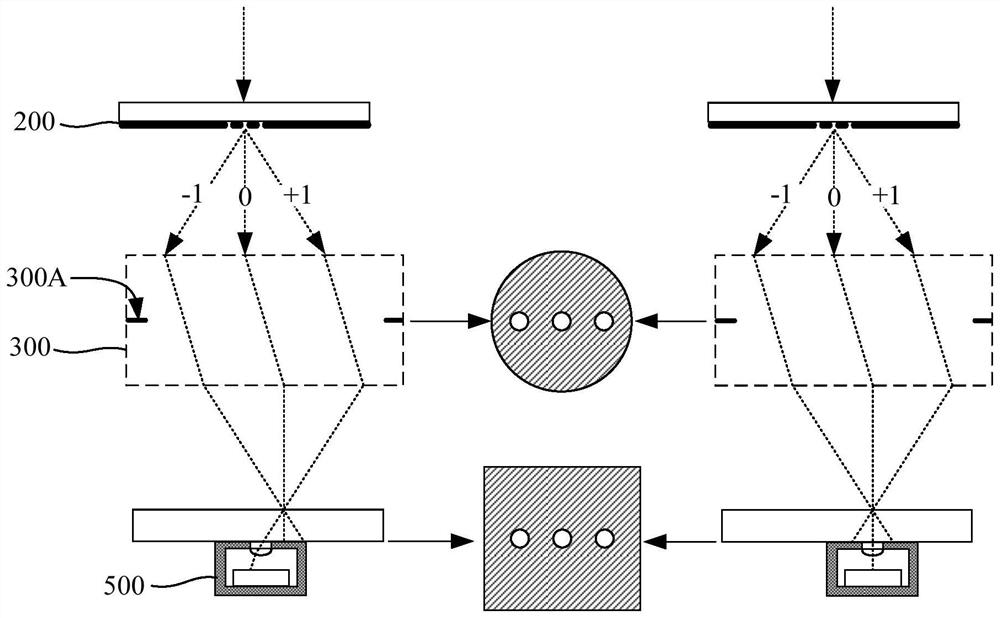

[0133] The difference from Embodiment 1 is that, in the lithography apparatus in this embodiment, the incident angle of the incident light irradiated on the phase mask can be adjusted, so that the incident light can be irradiated to the phase mask at different incident angles .

[0134] In this embodiment, the incident angle of the incident light irradiated on the phase mask can be adjusted by adjusting the light beam provided by the illumination system. Specifically, for example, the angle of the beam provided by the illumination system is deflected (that is, the beam is a deflectable beam), and then the projected beam is deflected, and the incident light irradiated on the phase mask is correspondingly deflected.

[0135] Image 6 It is a schematic diagram of the optical path when the incident light irradiated onto the phase reticle is deflected in the lithography apparatus with pupil transmittance detection function in Embodiment 2 of the present invention; Figure 7 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com