Building engineering concrete structure strength detection device

A technology for concrete structure and strength detection, which is applied to measuring devices, material inspection products, instruments, etc., can solve problems such as adjustment of detection probes, shaking of concrete slabs, and inability to meet people's needs, and achieve the effect of flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

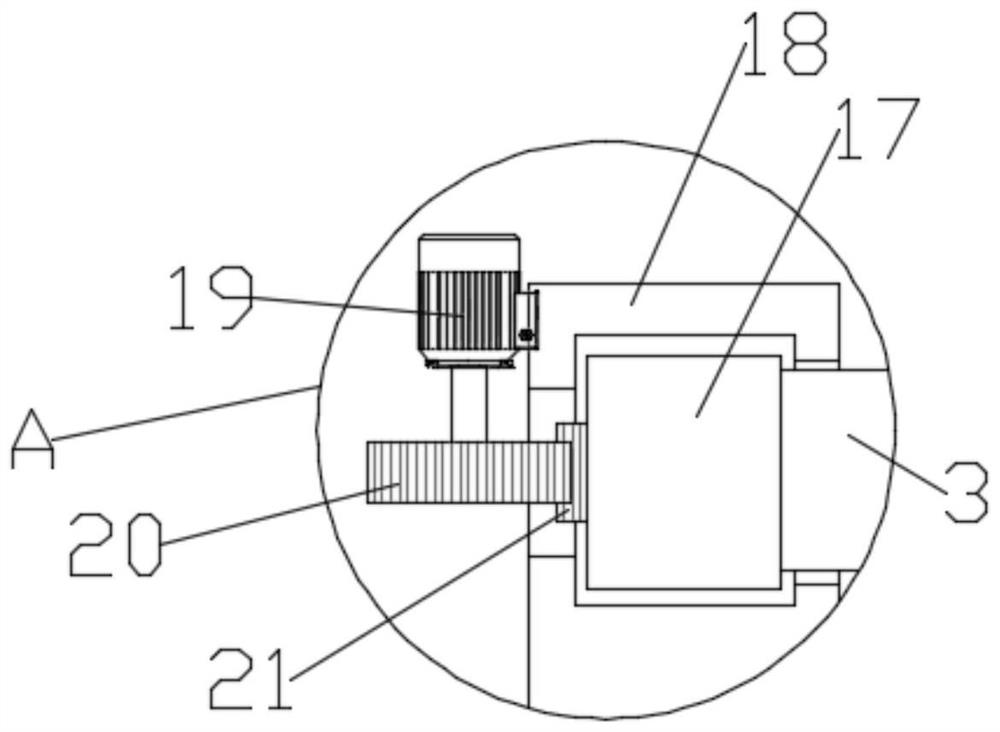

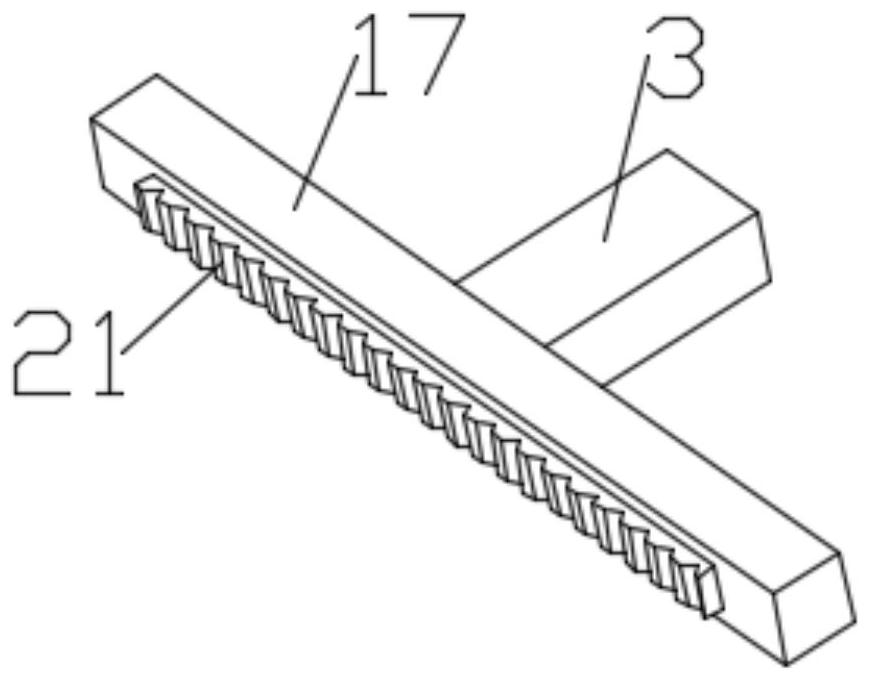

[0026] Such as figure 1 As shown, in the embodiment provided by the present invention, a construction engineering concrete structure strength detection device includes a support platform 1, the four corners of the support platform 1 are provided with support legs 2, and one side of the support platform 1 is provided with There is a height-adjusting assembly for adjusting the height of the support beam 3, the support beam 3 is provided with a support screw 12 for rotation, and the end of the support beam 3 is provided with a second positive shaft for driving the support screw 12 to rotate. Inverting the servo motor 13, the support beam 3 is also horizontally slid to be provided with a motion slider 14, and the motion slider 14 is sleeved on the support screw 12 through a threaded connection, and the motion slider 14 is provided with Support 15, the bottom end of the support 15 is provided with a detection probe 16, therefore, according to the embodiment of the present invention...

Embodiment 2

[0031] Such as figure 1 As shown, in the embodiment provided by the present invention, a construction engineering concrete structure strength detection device includes a support platform 1, the four corners of the support platform 1 are provided with support legs 2, and one side of the support platform 1 is provided with There is a height-adjusting assembly for adjusting the height of the support beam 3, the support beam 3 is provided with a support screw 12 for rotation, and the end of the support beam 3 is provided with a second positive shaft for driving the support screw 12 to rotate. Inverting the servo motor 13, the support beam 3 is also horizontally slid to be provided with a motion slider 14, and the motion slider 14 is sleeved on the support screw 12 through a threaded connection, and the motion slider 14 is provided with Support 15, the bottom end of the support 15 is provided with a detection probe 16, therefore, according to the embodiment of the present invention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com