LED illumination light source construction method for product surface defect detection

A technology of LED lighting and construction methods, which is applied in the directions of measuring devices, optical testing of flaws/defects, and material analysis through optical means, and can solve problems affecting the dynamic range and accuracy of CCD sensor scanning sampling and limited installation space of lighting sources, etc. Achieve good diffusion effect, low power consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The present invention will be further described below in conjunction with the accompanying drawings of the specification.

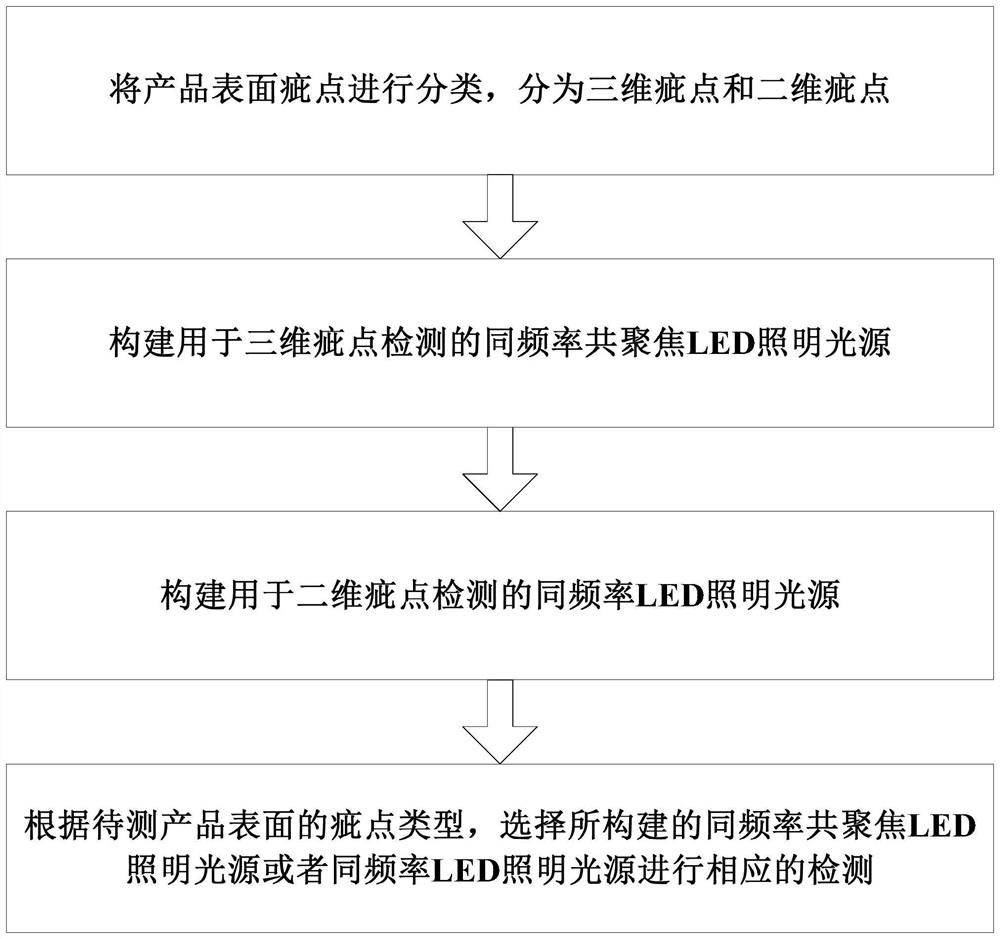

[0042]Such asfigure 1 As shown, the method for constructing an LED lighting source for detecting product surface defects of the present invention includes the following steps:

[0043]Step (A) classify the product surface defects into three-dimensional defects and two-dimensional defects. The three-dimensional defects are those that are inconsistent with the surface of qualified products and are characterized by three-dimensional surface features; the two-dimensional defects are those that are consistent with qualified products. Inconsistent surfaces, defects characterized by two-dimensional surface features, defects characterized by three-dimensional surface features, including protrusions, depressions, etc.; two-dimensional surface defects, including heterogeneous color, stains, damage, etc., among which three-dimensional defects require Parallel light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com