Angular contact ball bearing pre-tightening spacer ring measuring device and using method thereof

A technology of angular contact ball bearings and measuring devices, which is applied in the direction of measuring devices, mechanical bearing testing, and the use of stable tension/pressure to test the strength of materials, etc. It can solve problems such as the inability to meet the adjustment requirements of machine tool spindle bearings, and achieve flexible use. The effect of improving the rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

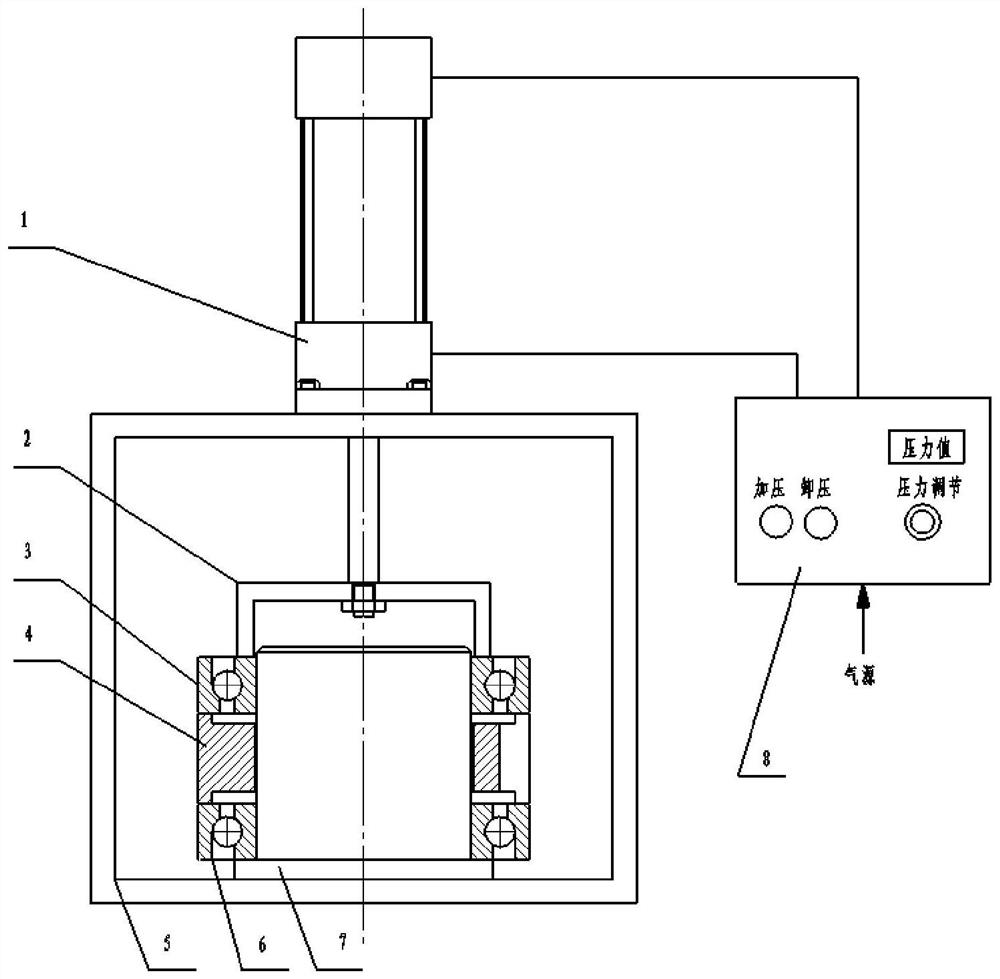

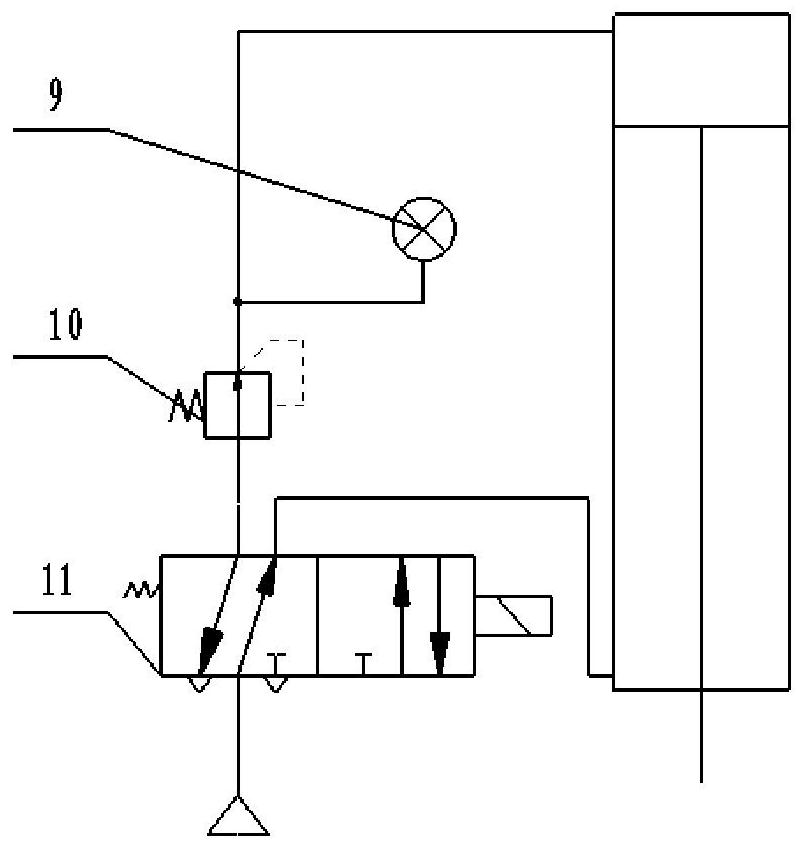

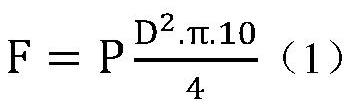

Embodiment 1

[0040] Taking the adjustment of NSK7018C angular contact ball bearings on the spindle of the machining center as an example, the front bearing 3 and the rear bearing 6 are installed on the shaft 7 in a back-to-back manner, and the fixed value spacer ring 4 is placed between the front bearing 3 and the rear bearing 6 for adjustment. Support, the fixed value spacer ring 4 is in contact with the outer rings of the two bearings, put the shaft 7 of the bearing group into the frame base 5 and lock it in the positioning slot at the bottom of the frame base 5, press the sleeve 2 It is on the same axis as the shaft 7, so that the pressure sleeve 2 corresponds to the place where the bearing group needs to be pressurized. Press the pressurization button on the control box 8, and the cylinder drives the pressure sleeve to move downward to apply pre-tightening force to the bearing. Table 1 shows the average value of preload and axial clearance of NSK bearing 70C series. In order to reduce t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com