Sealing structure for boiler reciprocating grate

A technology of reciprocating grate and sealing structure, which is applied in the direction of grate, movable grate, combustion method, etc., can solve the problems such as shutting down the furnace to put ash and affecting the operating efficiency of the boiler, so as to reduce the shutdown of the boiler and ensure the continuous operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

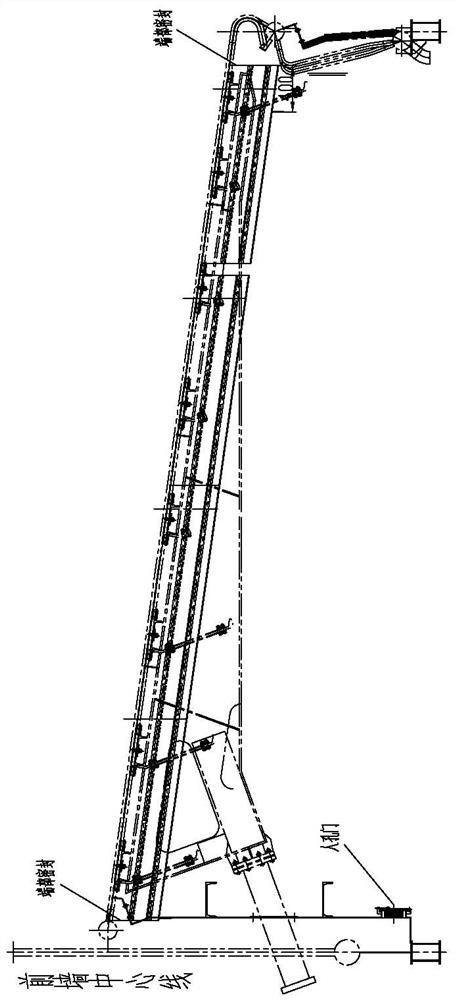

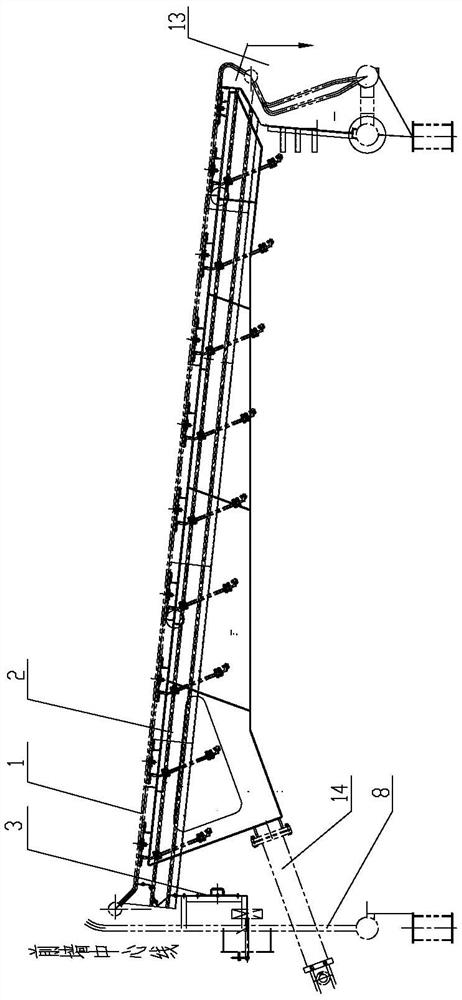

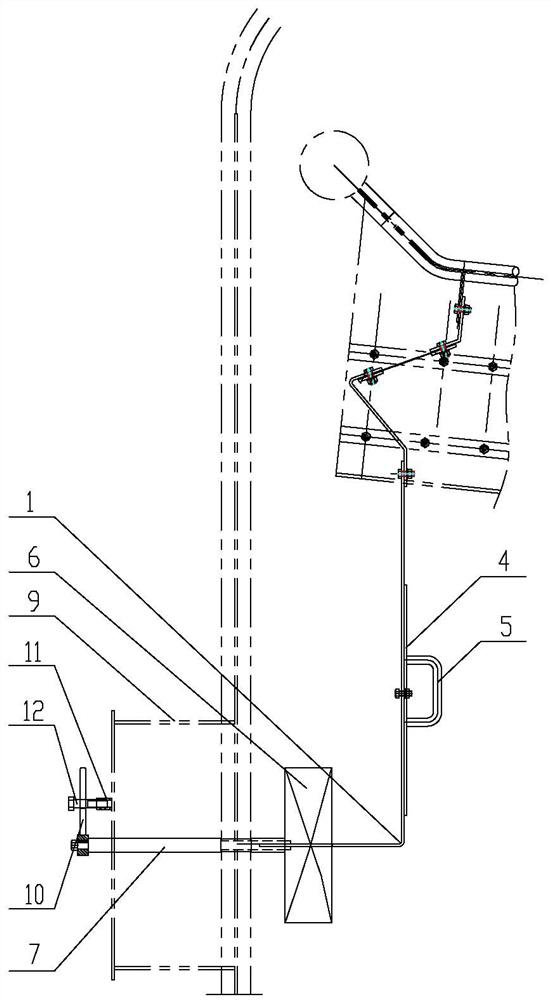

[0012] See figure 2 with image 3 As shown, a sealing structure for a boiler reciprocating grate, which includes a reciprocating grate 1, side sealing plates 2 are arranged on the left and right sides of the reciprocating grate 1, and a front sealing plate 3 is arranged under the front end of the reciprocating grate 1, A manhole door is arranged on the side of the front sealing plate 3, and a manhole door plate 4 is installed at the manhole door. The manhole door plate 4 is fixed on the side of the front sealing plate 3 by screws and a handle 5 is installed on the outer wall, which can be easily disassembled. The bottom of the plate 3 is equipped with a movable ash door panel 6, the movable ash door panel 6 is connected to one end of the transmission shaft 7, and the other end of the transmission shaft 7 runs through the front wall 8 and the sealing casing 9 fixed on the front wall 8 and is equipped with a rotating handle 10, sealed A positioning sleeve 11 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com