A kind of supercritical CO2 multistage throttling device and method

A supercritical and critical pressure technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as damage to pipelines and ancillary equipment, affecting the safe discharge of pipelines, hidden dangers, etc., to avoid low temperature damage , the effect of alleviating the fluid temperature drop and the degree of temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

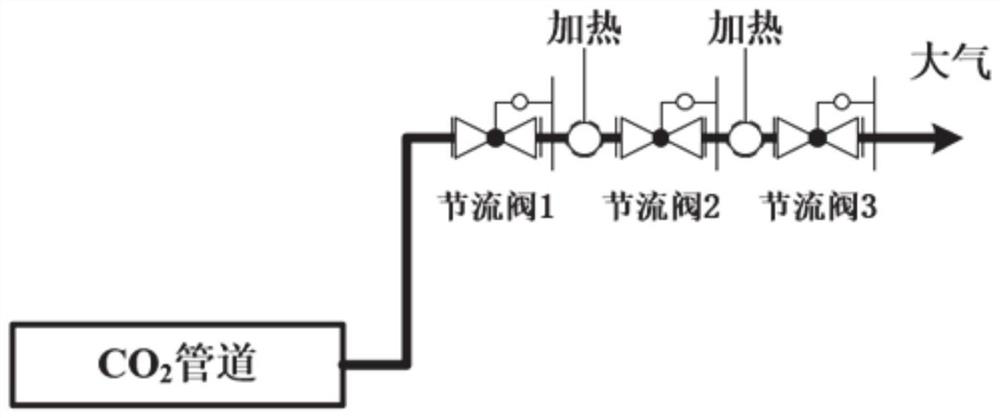

[0037] In a typical embodiment of the present disclosure, such as Figure 2-Figure 6 shown, a supercritical CO 2 Multi-stage throttling device.

[0038] It mainly includes a throttle valve and a heating mechanism arranged on the venting pipe, wherein at least one throttle valve and one heating mechanism are respectively arranged, and the throttle valve and the heating mechanism are alternately arranged on the venting pipe, and the venting pipe is connected to conveying The pipeline and throttle valve adjust the flow rate conveyed by the venting pipe, and the heating mechanism heats the medium in the venting pipe.

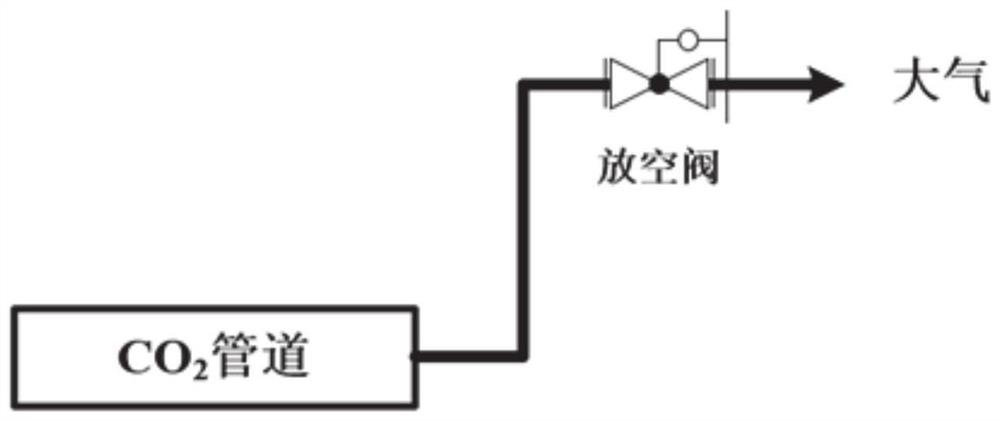

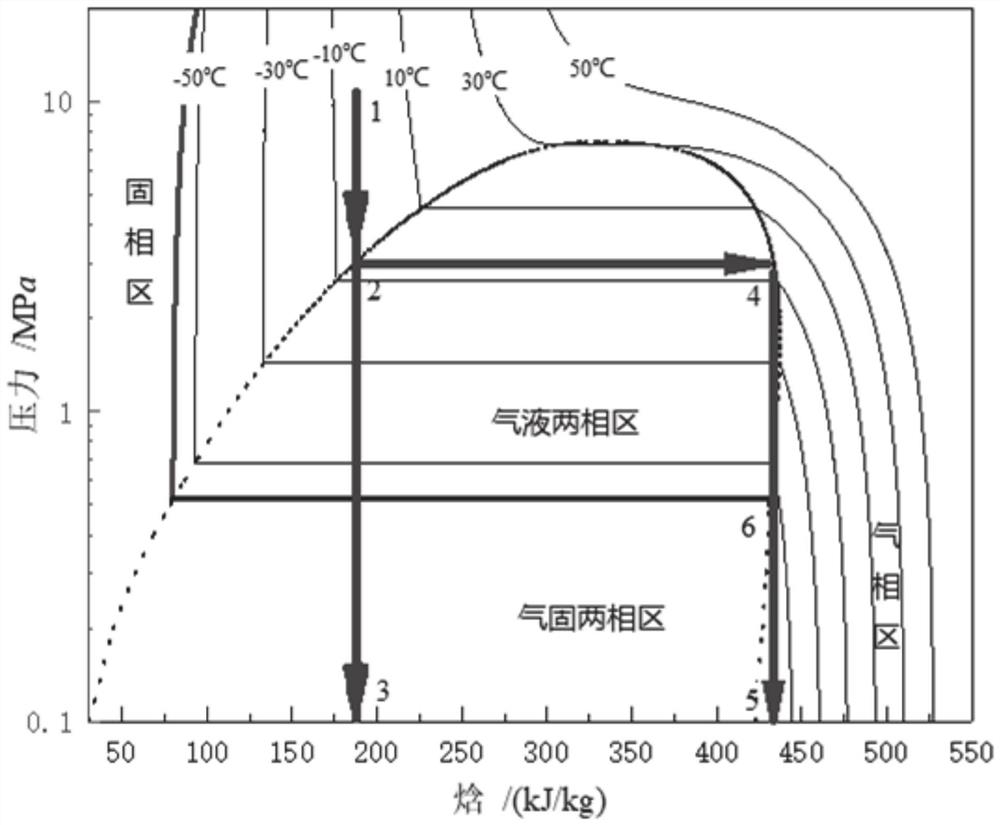

[0039] for figure 1 In the existing technology, the process of directly venting the conveying pipeline directly, in the CO 2 The pipeline is depressurized to atmospheric pressure through the vent line. First at the vent valve, CO 2 The pressure inside the pipe is reduced to atmospheric pressure, so the CO released 2 The temperature is the same as its boiling p...

Embodiment 2

[0045] In another exemplary embodiment of the present disclosure, as Figure 2-6 shown, given a supercritical CO 2 Multi-stage throttling method.

[0046] Determining throttling and venting of supercritical CO 2 The process does not produce the minimum endothermic heat of dry ice, the calculation will convert the high pressure CO 2 temperature when throttled above critical pressure;

[0047] The temperature calculation model of pipeline throttling and orifice throttling is established, and it is judged that if the temperature after throttling is lower than the triple point temperature, the supercritical CO 2 The classification will be above the critical pressure, and the temperature will be maintained above the triple point temperature;

[0048] Determine the heating power required for throttling at all levels, configure parameters according to the critical pressure ratio, and convert the supercritical CO 2 Throttled to atmospheric pressure.

[0049] Among them, when it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com