Stainless steel anti-fracture steel plate

A kind of anti-fracture, stainless steel technology, applied in the direction of sheet/plate, thin plate connection, connecting components, etc., can solve the problems of stainless steel plate fracture, stainless steel plate stress change, steel plate load capacity decline, etc., to increase the load capacity, prevent falling off, solve the problem The effect of reduced load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

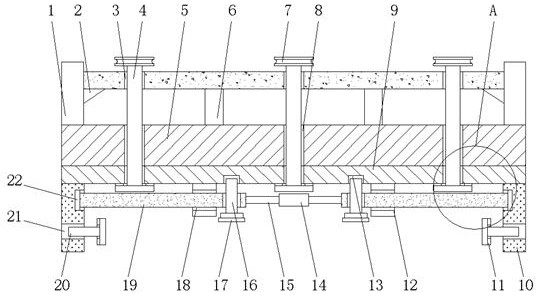

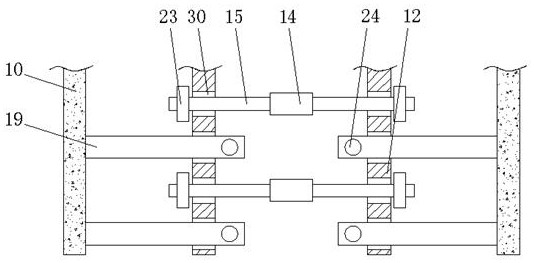

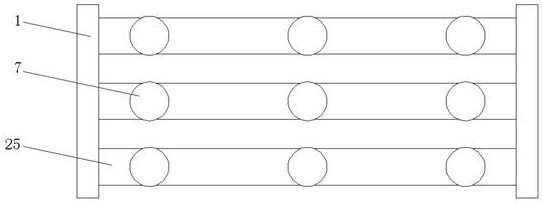

[0028] see Figure 1-5, in this embodiment: a stainless steel anti-fracture steel plate, including a steel plate 5, the bottom surface of the steel plate 5 is fixedly connected with a fixed plate 9, the bottom of the fixed plate 9 is provided with two mounting plates 10, the upper surface of each mounting plate 10 is Fixedly connected with the bottom surface of the steel plate 5, a group of slots 26 are provided on the sides of the two mounting plates 10 close to each other, and two connecting bars 12 are arranged below the fixing plate 9, and the right side of each connecting bar 12 is provided with There is a group of through grooves 18, the upper surface of each connecting bar 12 is fixedly connected with the bottom surface of the mounting plate 10, each slot 26 is provided with a board 19, and the two groups of boards 19 are connected to each other on one side respectively. Two groups of through-slots 18 extend to the outside of the through-slots 18, a group of through-hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com