Clamping device

一种夹持装置、夹持件的技术,应用在夹钳、摩擦夹紧的可卸紧固件、连接构件等方向,能够解决无法快速完成夹持与拆卸、夹持力道不平均、夹持力道小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

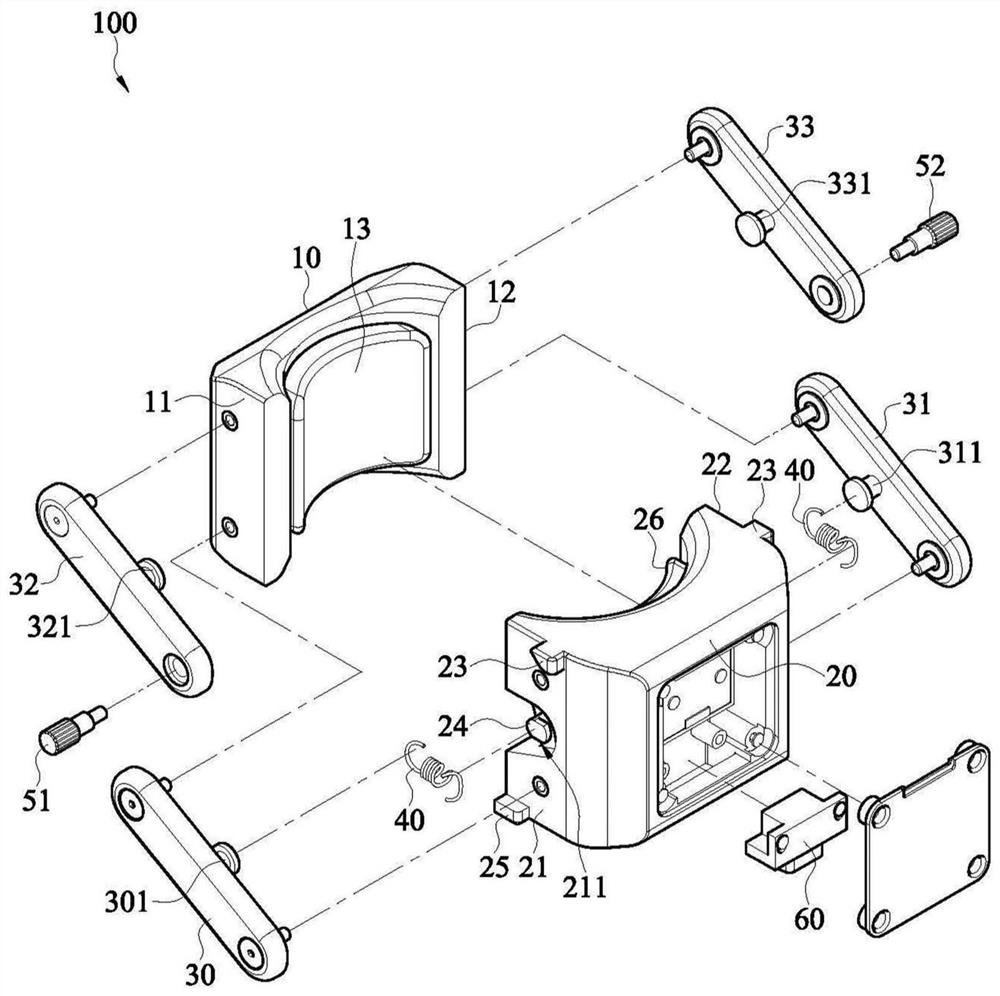

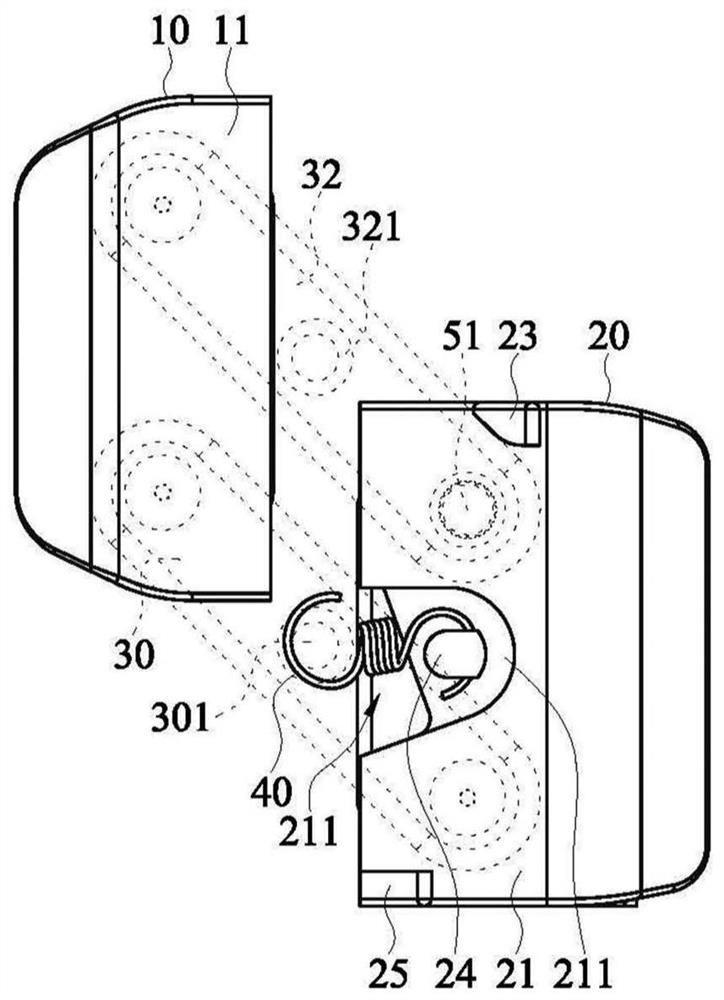

[0048] Please see first figure 1 and figure 2 , figure 1 is a perspective view of a clamping device according to an embodiment of the present disclosure, figure 2 is an exploded view of a clamping device according to an embodiment of the present disclosure, image 3 Is a side partial perspective view of a clamping device according to an embodiment of the present disclosure. The clamping device 100 of this embodiment includes a first clamping member 10 , a second clamping member 20 , a first connecting rod 30 , a second connecting rod 31 , a third connecting rod 32 , a fourth connecting rod 33 and an elastic member 40 . In other embodiments, only the first connecting rod 30 and the second connecting rod 31 may be provided, and the third connecting rod 32 and the fourth connecting rod 33 may be omitted, and the clamping effect can also be achieved, which will be described in detail later.

[0049] Depend on figure 1 and figure 2 It can be seen that the first clip 10 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com