Preparation method of antibacterial and anti-mite fabric

A technology for fabrics and mixing equipment, which is applied in chemical instruments and methods, biochemical fiber treatment, woven fabrics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

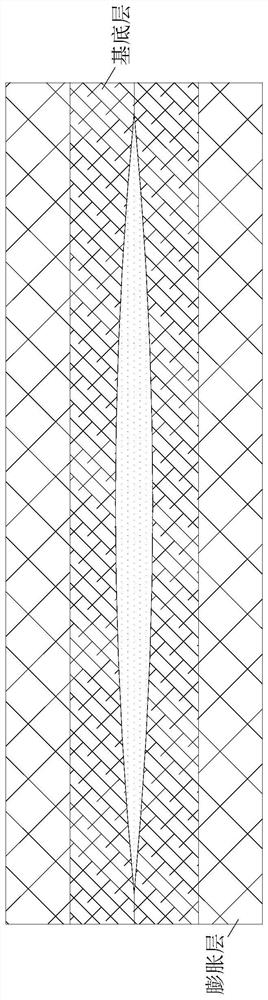

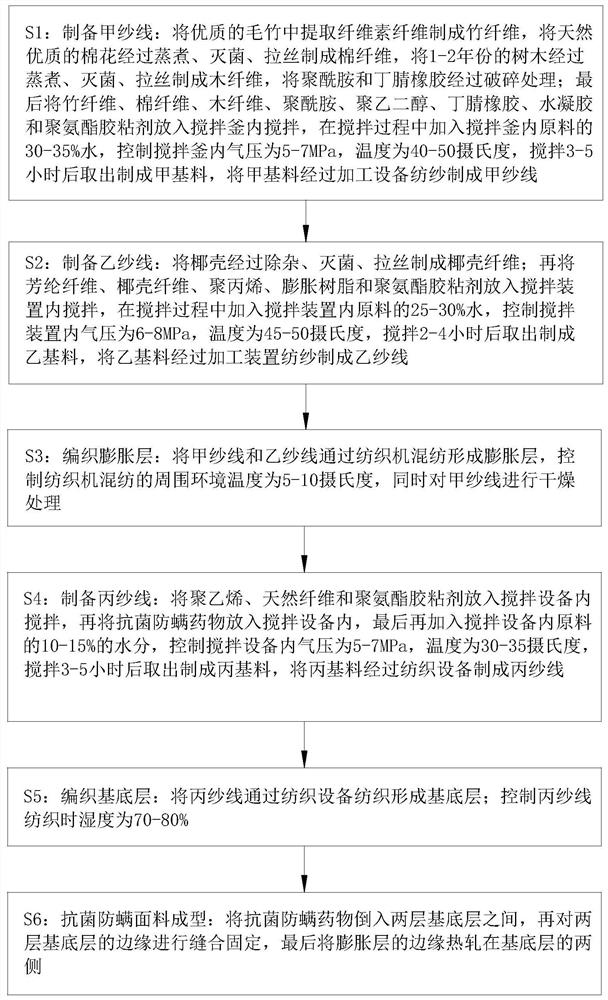

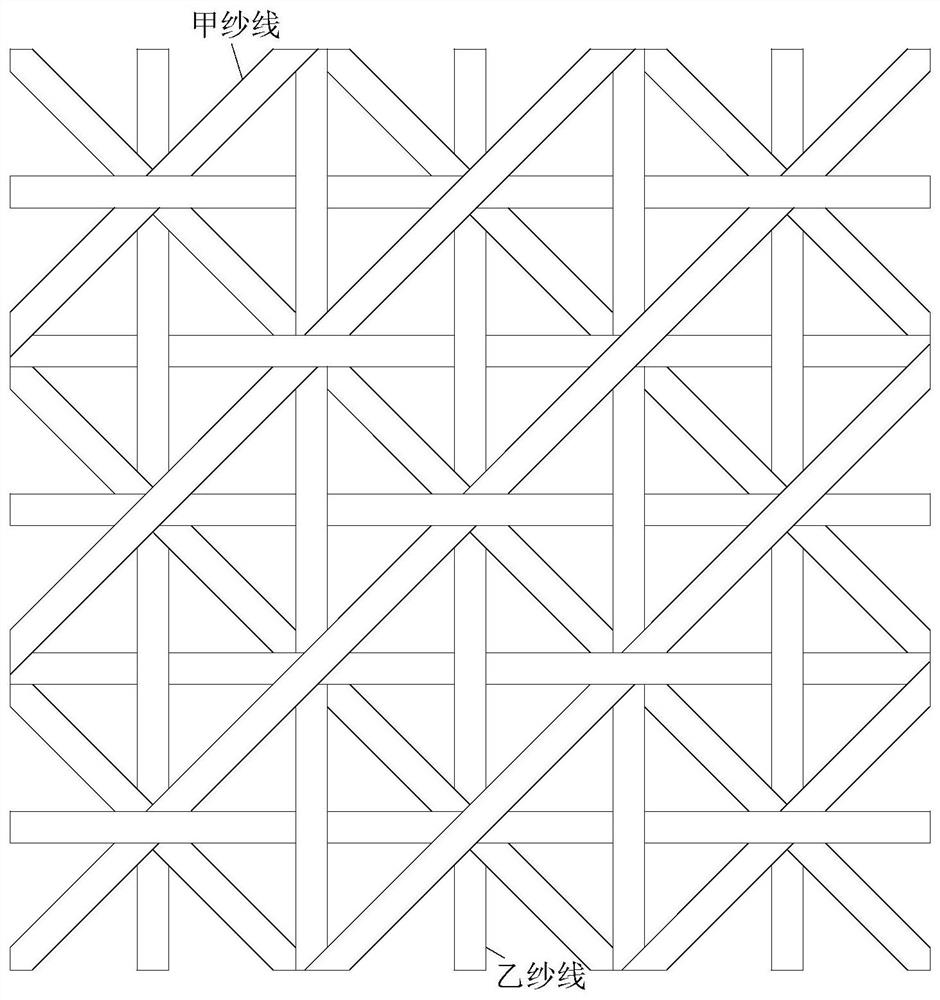

Embodiment 1

[0040] The antibacterial and anti-mite fabric includes a base layer and an expansion layer; the base layer and the expansion layer are two layers, the base layer is located between the two expansion layers, and the two base layers are filled with antibacterial and mite-removing drugs; the The antibacterial and mite-removing drug is powdery; the swelling layer is woven from the first yarn and the second yarn; the first yarn has the effect of absorbing water and swelling, and the first yarn includes the following components in parts by weight: 20 parts of bamboo fiber , 30 parts of cotton fiber, 15 parts of wood fiber, 5 parts of polyamide, 10 parts of polyethylene glycol, 3 parts of nitrile rubber, 4 parts of hydrogel, 5 parts of polyurethane adhesive; the second yarn has the effect of thermal expansion , the second yarn includes the following components in parts by weight: 30 parts of aramid fiber, 15 parts of coconut fiber, 5 parts of polypropylene, 1 part of expansion resin, ...

Embodiment 2

[0042] The antibacterial and anti-mite fabric includes a base layer and an expansion layer; the base layer and the expansion layer are two layers, the base layer is located between the two expansion layers, and the two base layers are filled with antibacterial and mite-removing drugs; the The antibacterial and mite-removing medicine is powdery; the expansion layer is woven from a yarn and a second yarn; the first yarn has the effect of absorbing water and swelling, and the first yarn includes the following components in parts by weight: 21 parts of bamboo fiber , 31 parts of cotton fiber, 16 parts of wood fiber, 6 parts of polyamide, 11 parts of polyethylene glycol, 4 parts of nitrile rubber, 5 parts of hydrogel, 6 parts of polyurethane adhesive; the second yarn has the effect of thermal expansion , the second yarn includes the following components in parts by weight: 31 parts of aramid fiber, 16 parts of coconut fiber, 6 parts of polypropylene, 1 part of expansion resin, and 6...

Embodiment 3

[0044] The antibacterial and anti-mite fabric includes a base layer and an expansion layer; the base layer and the expansion layer are two layers, the base layer is located between the two expansion layers, and the two base layers are filled with antibacterial and mite-removing drugs; the The antibacterial and mite-removing medicine is powdery; the expansion layer is woven from the first yarn and the second yarn; the first yarn has the effect of absorbing water and swelling, and the first yarn includes the following components in parts by weight: 22 parts of bamboo fiber , 32 parts of cotton fiber, 17 parts of wood fiber, 7 parts of polyamide, 12 parts of polyethylene glycol, 5 parts of nitrile rubber, 6 parts of hydrogel, 7 parts of polyurethane adhesive; the second yarn has the effect of thermal expansion , the second yarn includes the following components in parts by weight: 32 parts of aramid fiber, 17 parts of coconut fiber, 7 parts of polypropylene, 2 parts of expansion r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com