A kind of carboxyl-containing polyphenolic compound secondary doping polyaniline epoxy resin coating and preparation method thereof

A polyaniline epoxy resin, secondary doping technology, applied in the field of coatings, can solve the problems of solvent-based coating pollution, polyaniline dispersion, poor stability, etc., to improve corrosion resistance, reduce viscosity, improve dispersion sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

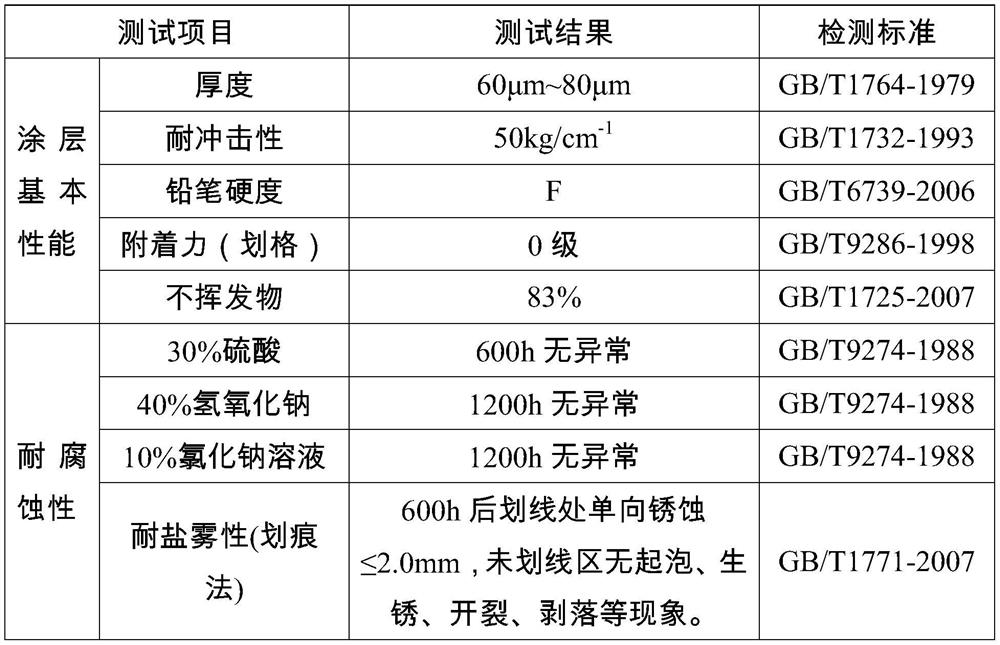

Embodiment 1

[0034] 1. Synthesis of polyaniline:

[0035] Preparation of doped polyaniline once:

[0036] Preparation of liquid C: Add 4.65g of aniline monomer into 200mL of dichloroethane, and stir evenly;

[0037]Preparation of liquid D: Dissolve 20g of p-toluenesulfonic acid in 400mL of aqueous solution, then add 11.4g of ammonium persulfate into the aqueous solution and stir evenly; carefully transfer liquid C (liquid D) into liquid D (liquid C) and keep the reaction The temperature is 0°C, stirring slowly, after 24 hours, the reaction is complete, the product obtained is washed with deionized water until neutral, then washed with ethanol to obtain the product, washed with deionized water until neutral, washed with ethanol for 3 times, suction filtered and dried Obtain a p-toluenesulfonic acid doped polyaniline product;

[0038] Preparation of intrinsic polyaniline:

[0039] Put the polyaniline obtained by one-time doping into a sufficient amount of 0.1mol / L ammonia solution, stir i...

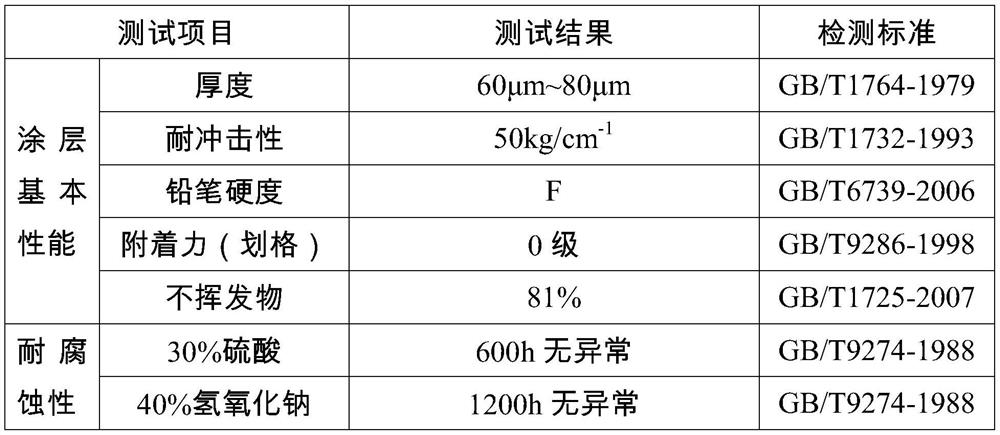

Embodiment 2

[0049] 1. Synthesis of polyaniline:

[0050] Preparation of doped polyaniline once:

[0051] Prepare liquid C: add 4.65g of aniline monomer and 5.4g of p-phenylenediamine into 250mL of toluene, and stir well;

[0052] Preparation of liquid D: Add 27.36g of ammonium persulfate into 400mL of 1M hydrochloric acid aqueous solution and stir evenly; carefully transfer liquid C (liquid D) into liquid D (liquid C), keep the reaction temperature at 0°C, and stir slowly. After 24 hours, the reaction Complete, wash the obtained product with deionized water to neutrality, then rinse with ethanol to obtain the product, wash with deionized water to neutrality, then rinse with ethanol for 3 times, filter with suction and dry to obtain a polyaniline product doped with hydrochloric acid once;

[0053] Preparation of intrinsic polyaniline:

[0054] Put a certain amount of polyaniline doped once into a sufficient amount of 0.1mol / L ammonia solution, stir evenly and let it stand for 2 hours. Af...

Embodiment 3

[0064] 1. Synthesis of polyaniline:

[0065] Preparation of doped polyaniline once:

[0066] Prepare liquid C: add 4.65g of aniline monomer into 250mL of chloroform, and stir evenly;

[0067] Preparation of liquid D: Dissolve 20g of citric acid in 400mL of aqueous solution, then add 11.4g of ammonium persulfate into the aqueous solution, and stir evenly; carefully transfer liquid C (liquid D) into liquid D (liquid C), and keep the reaction temperature at Stir slowly at 0°C. After 24 hours, the reaction is complete. Wash the obtained product with deionized water to neutrality, then rinse with ethanol to obtain the product, wash with deionized water to neutrality, then rinse with ethanol for 3 times, suction filter and dry to obtain lemon Acid doped polyaniline product once;

[0068] Preparation of intrinsic polyaniline:

[0069] Put a certain amount of polyaniline doped once into a sufficient amount of 0.1mol / L ammonia solution, stir evenly and let it stand for 2 hours. Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com