Resistance reducing agent and preparation method thereof

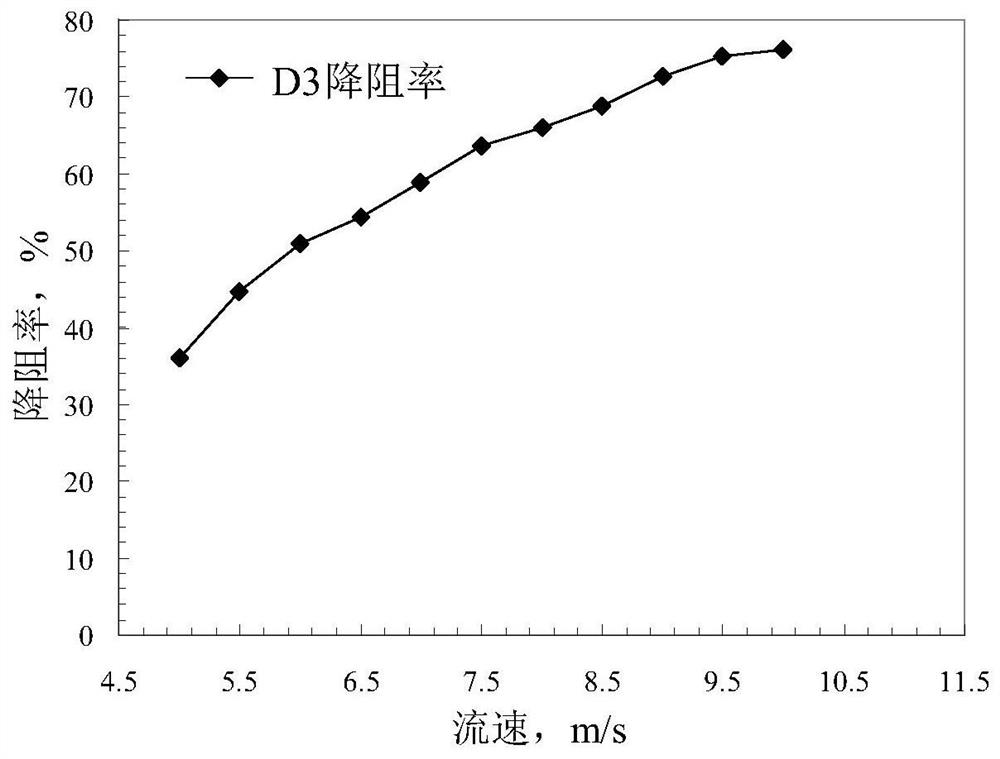

A drag-reducing agent and initiator technology, which is applied in the field of drag-reducing agent and its preparation, can solve the problems of poor water solubility, high cost, complicated synthesis operation of drag-reducing agent, achieve good stability, reduce preparation cost, and improve fracturing The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The embodiment of the present invention provides a preparation method of a drag reducing agent, the preparation method comprising:

[0057] Step 1: According to the mass parts of each component, add acrylamide and alkyl polyethylene glycol acrylate two monomers into the reactor, add acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid or p- At least one monomer in sodium styrene sulfonate is also added into the reactor to obtain a mixture solution, and the pH of the mixture solution is adjusted to 8-9.

[0058] In this step, 60-95 parts by mass of acrylamide and 1-5 parts by mass of alkyl polyethylene glycol acrylate are added into the reactor. And, at least one of acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid, or sodium p-styrenesulfonate is also added to the reactor, and then the pH of the mixture is adjusted.

[0059] Wherein, the mass fraction of acrylic acid does not exceed 10 mass fractions, the mass fraction of 2-acrylamide-2-methylpropanesulfonic a...

Embodiment 1

[0077] This embodiment provides a drag reducing agent, and its drag reducing rate is measured. Wherein, the preparation method of the drag reducing agent comprises:

[0078] According to the mass parts of each component, 85 mass parts of acrylamide, 5 mass parts of octadecyl polyethylene glycol methacrylate, and 10 mass parts of acrylic acid are added to the reactor to obtain a mixture solution. solution to adjust the pH of the mixture solution to 8-9; add water to prepare an aqueous solution with a total monomer mass concentration of 20%, and pass N 2 30min; add 0.1% of the total monomer mass of azobisisobutylamidine hydrochloride, stir evenly, place in a 55°C water bath, and react for 5h to obtain a milky white jelly product; wash the milky white jelly with ethanol , dried and pulverized to obtain the drag reducing agent. For ease of distinction, the drag reducing agent is named D1.

[0079] The assay method of this drag reducing agent D1 comprises:

[0080] Take 20L of...

Embodiment 2

[0083] This embodiment provides a drag reducing agent, and its drag reducing rate is measured. Wherein, the preparation method of the drag reducing agent comprises:

[0084] According to the mass parts of each component, 85 mass parts of acrylamide, 3 mass parts of octadecyl polyethylene glycol acrylate, 7 mass parts of acrylic acid, 5 mass parts of 2-acrylamide-2-form Propanesulfonic acid is added in the reactor, obtains the mixture solution, the pH of the mixture solution is adjusted to 8~9 by NaOH solution; 2 30min; add 0.1% of the total monomer mass of azobisisobutylamidine hydrochloride, stir evenly, place in a 55°C water bath, and react for 5h to obtain a milky white colloidal product; mix the milky white colloidal product with ethanol After washing, drying and crushing, the drag reducing agent is obtained. For ease of distinction, the drag reducing agent is named D2.

[0085] The assay method of this drag reducing agent D2 comprises:

[0086] Take 20L of clear wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com