Wire winding device for optical fiber production

A technology for coiling and optical fibers, applied in the field of coiling devices for optical fiber production, can solve the problems of reduced production efficiency, increased labor intensity of workers, looseness, etc., and achieves the effect of improving work efficiency, reducing labor intensity, and improving winding quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

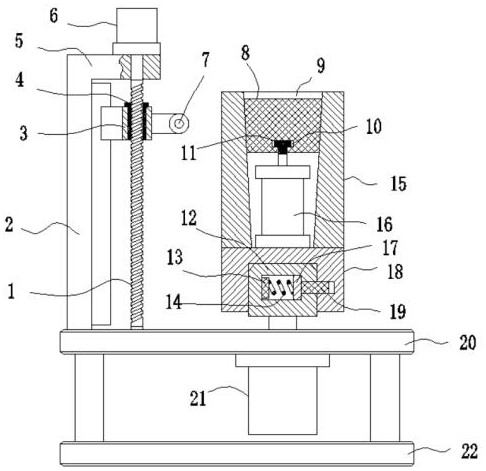

[0028] Such as Figure 1-2 As shown, a coiling device for optical fiber production includes:

[0029] bottom plate 22;

[0030] Mounting plate 20, described mounting plate 20 is horizontally arranged on the top of base plate 22 by installing a plurality of uprights;

[0031] Winding driving motor 21, described winding driving motor 21 is vertically installed on the mounting plate 20;

[0032] Turning seat 18, described turning seat 18 is driven and connected on the winding drive motor 21;

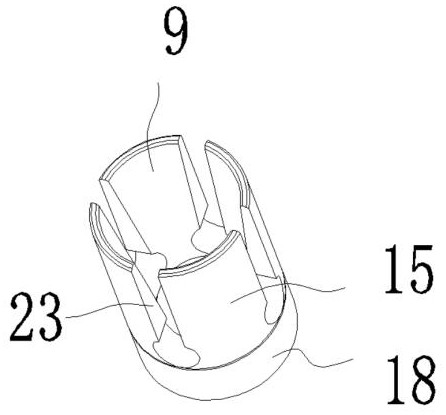

[0033] Collet 15, said collet 15 is coaxially arranged on the top of rotating seat 18, and conical groove 9 in the form of a through hole is coaxially provided on it, and the diameter of said conical groove 9 decreases successively from top to bottom, and said The circumferential surface of the collet 15 is provided with a plurality of strip-shaped notches 23 connecting the conical groove 9 along its axial array;

[0034] Wedge 8, the wedge 8 is a conical structure, and its shape is ada...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com