Method for improving poor bubbles of QFN bottom bonding pad and bonding pad

A technology of bottom pads and pads, applied in the electronic field, can solve problems affecting chip heat dissipation and PCBA reliability, and achieve the effects of improving reliability, reducing large bubbles, and ensuring conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

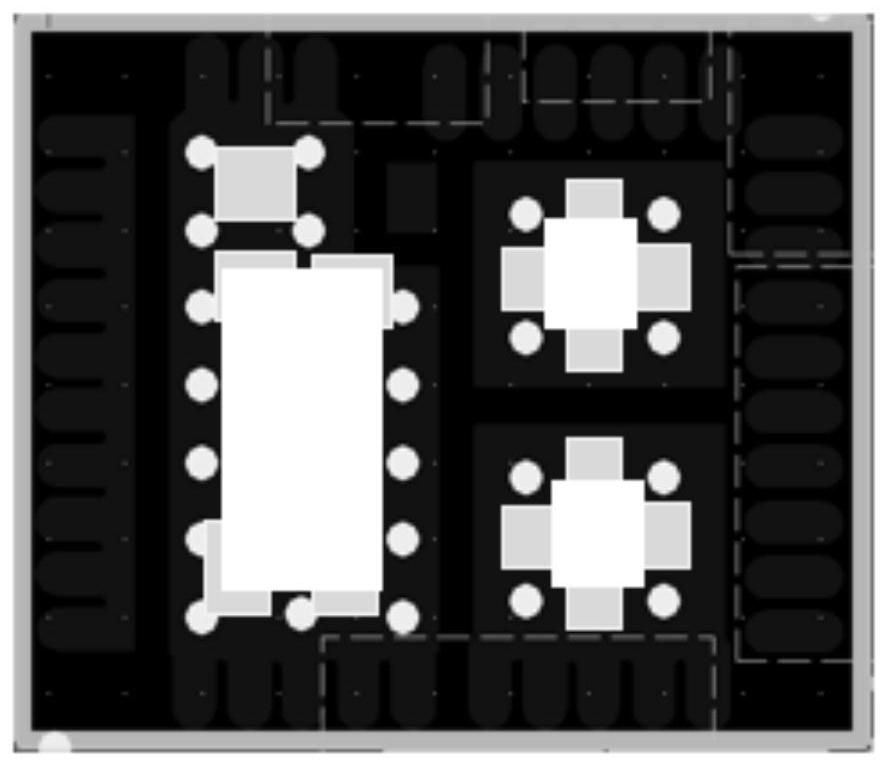

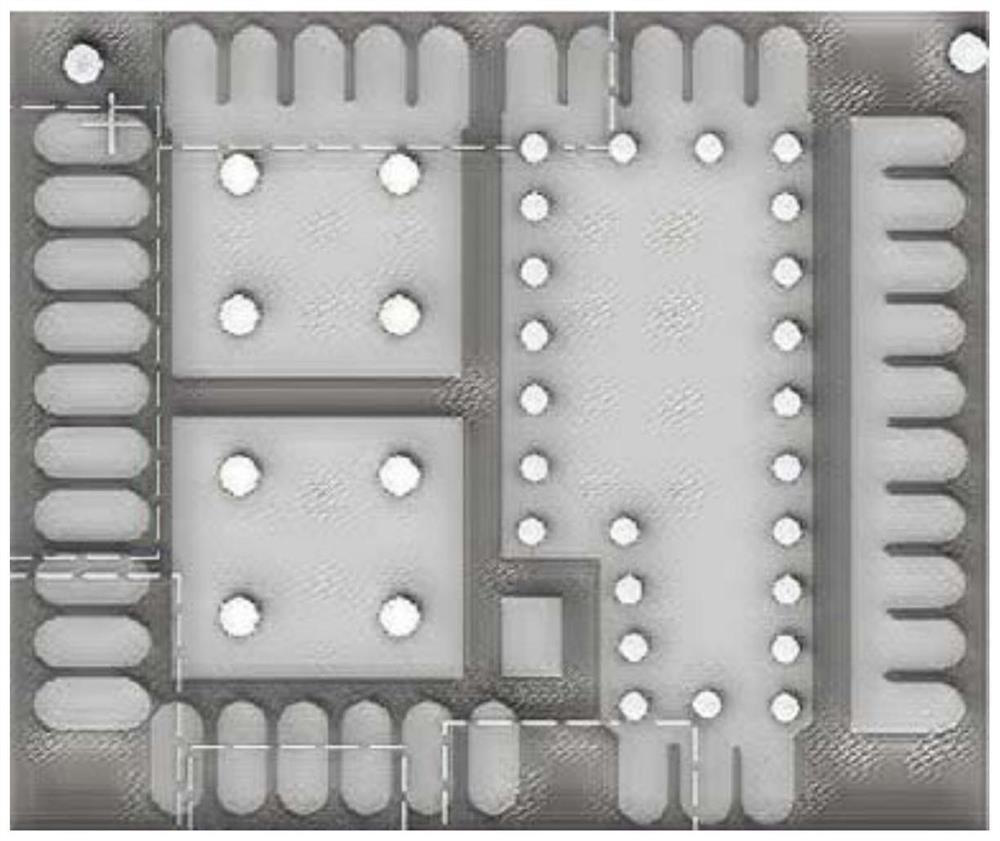

[0018] see figure 1 with figure 2 , the embodiment of the present invention includes:

[0019] See figure 1 , a method for improving the bad air bubbles of the QFN bottom pad, including: designing the position of the Via hole according to the shape of the QFN pad, canceling the Via hole in the middle of the pad, and appropriately adding some Via holes on the edge of the pad according to the actual size of the pad To meet the conductivity of PCBA. It can not only reduce the occurrence rate of air bubbles but also keep you ventilating and dissipating heat. In addition, it can better improve the poor air bubbles. According to the pad design of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com