A spray tower for oil fume treatment system

A technology for oil fume treatment and spray tower, which is applied in the direction of using tools for cleaning, cleaning methods and utensils, and the use of liquid separators, etc. Guaranteed normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

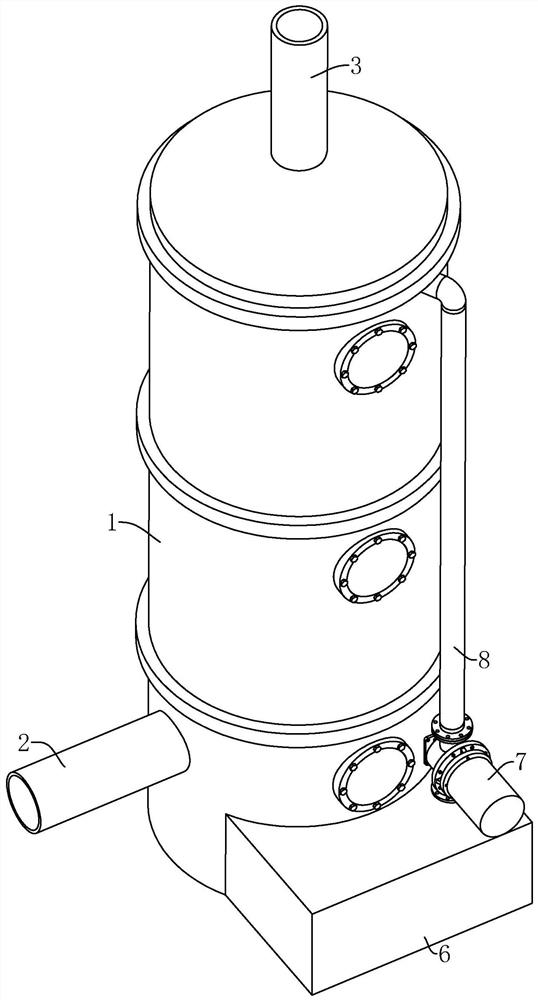

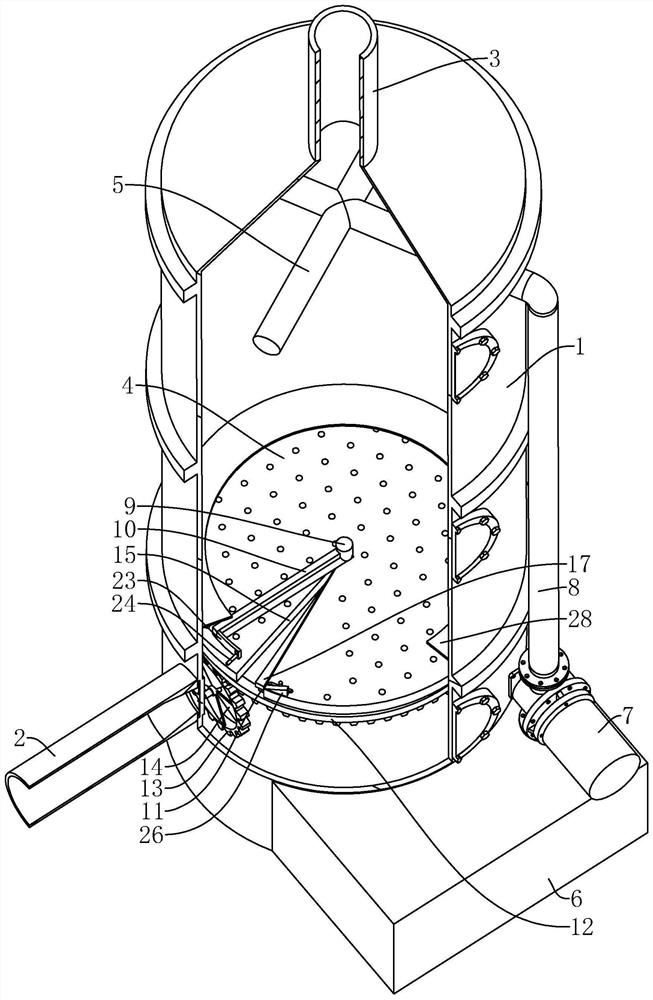

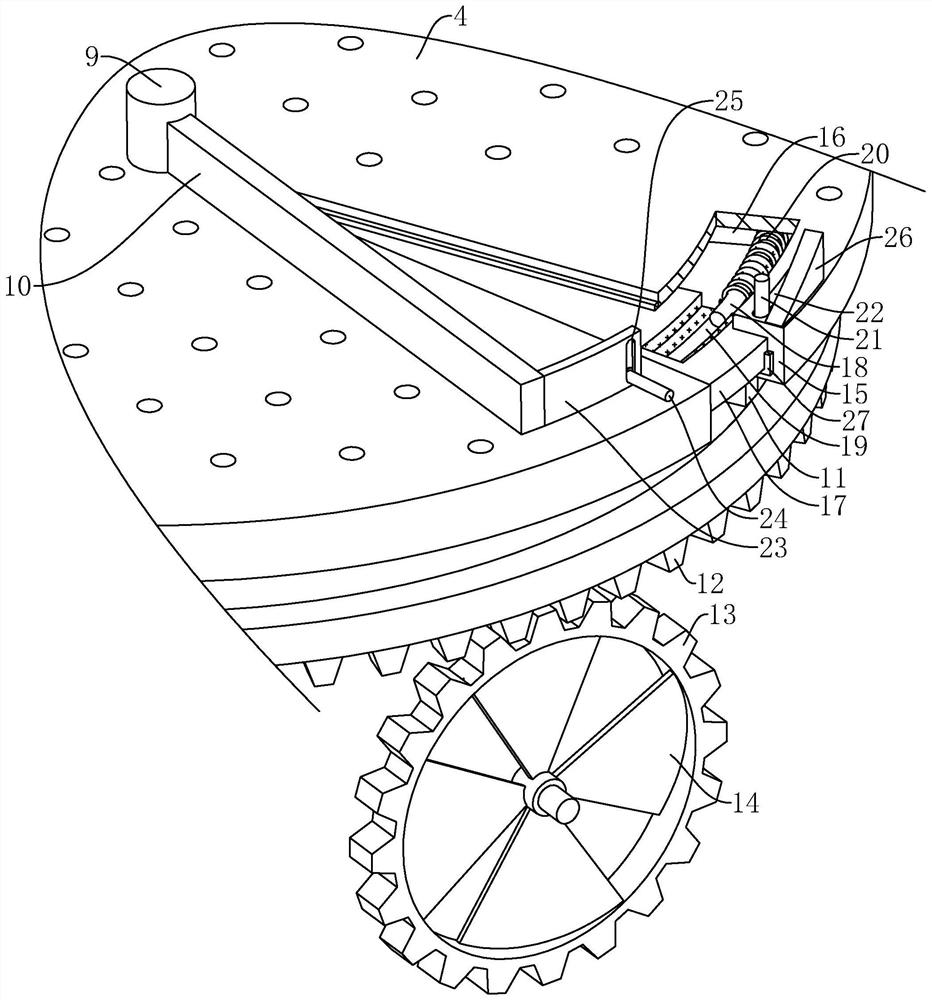

[0032] The following is attached Figure 1-3 The application is described in further detail.

[0033] refer to figure 1 and figure 2 , a spray tower for oil fume treatment system, including a hollow tower body 1, an air inlet pipe 2 and an air outlet pipe 3 that are fixedly connected to the tower body 1 and communicated with the inside of the tower body 1, and the air outlet pipe 3 is located in the air inlet pipe 2; the spray tower also includes an orifice 4 installed in the tower body 1 and between the inlet pipe 2 and the outlet pipe 3, the spray pipe 5 above the orifice 4, and the A water tank 6 , a water pump 7 placed in the water tank 6 , and a water delivery pipe 8 connected between the water pump 7 and the spray pipe 5 . The spray pipe 5, the water tank 6, the water pump 7 and the water delivery pipe 8 constitute the spray mechanism. When the spray tower is working, the water pump 7 pumps the water in the water tank 6 to the spray pipe 5 for spraying from top to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com