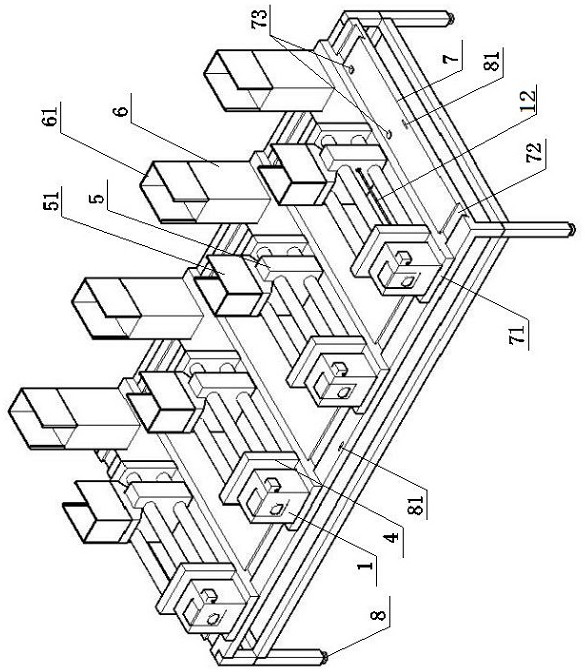

Test equipment for MB modular bridge expansion device and test method thereof

A technology of telescopic device and test equipment, which is applied in the direction of measuring device, testing of mechanical parts, testing of machine/structural parts, etc. Unreasonable relationship, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

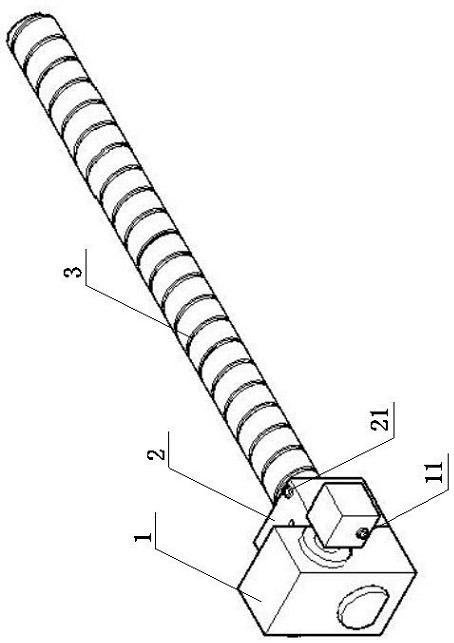

Embodiment 1

[0165] A test method for MB modulus bridge expansion device test equipment--the test method for the qualified judgment of the designed expansion and contraction, the qualified judgment of the assembly tolerance, and the qualified judgment of the load-bearing performance (the three-slot expansion device and the double-slit expansion device are only qualified for the load-carrying performance) When judging the test, it is necessary to replace the corresponding load-carrying performance test accessories, and the other test procedures are exactly the same, here we take the double-slit expansion device as an example):

[0166] Step 1. Judgment of the design expansion and contraction and the assembly tolerance in the compressed state:

[0167] 1. Sample fixation;

[0168] Place the MB modular bridge expansion device (hereinafter referred to as sample 10) in the test room at 23°C ± 5°C for no less than 24 hours. There should be no corrosive gas and vibration sources that affect the d...

Embodiment 2

[0213] A test method for the test equipment of the MB modular bridge expansion device - longitudinal dislocation test:

[0214] The difference between this embodiment and embodiment 1 lies in the following content:

[0215] In this test, by setting the controller 13, the leftmost mobile pedestal 5 of the test device of the present invention does not move freely throughout the whole process, and the middle mobile pedestal 5 is in a state of free movement. The box 104 is tested to simulate the situation of longitudinal dislocation at the expansion joints of the actual bridge.

[0216] When all step tests in embodiment 1 are qualified, change over to following test procedure:

[0217] Step A: Longitudinal misalignment test:

[0218] 1. Sample fixation;

[0219] Repeat the sample fixing link in step 1.

[0220] 2. Measure the longitudinal dislocation tension distance L 2 ;

[0221] Use a ruler to measure the distance between the leftmost and rightmost two telescopic displace...

Embodiment 3

[0242] A test method for the test equipment of the MB modular bridge expansion device--vertical dislocation test method:

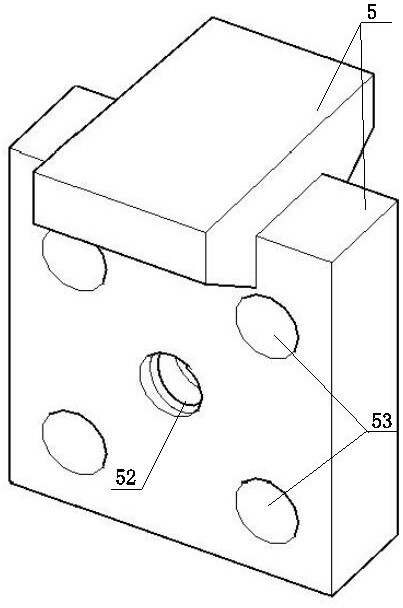

[0243] The difference between this embodiment and embodiment 1 lies in the following content:

[0244] In this test, the height of the sample telescopic displacement box 104 fixed by the second clamping part 61 of the test device of the present invention is constant, and the test is carried out after the sample telescopic displacement box 104 fixed by the first clamping part 51 is used to simulate the actual of bridges with vertical misalignment at expansion joints.

[0245] When all step tests are qualified in embodiment 1-2, change over to following test procedure:

[0246] Step B: Vertical misalignment test:

[0247] The test conditions are the same as in Example 1.

[0248] 1. Sample fixation;

[0249] Before the sample is fixed in step 1, the front part of the sample telescopic displacement box 104 (that is, the part clamped by the first clamping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com