A novel variable pressure differential load sensing system for quantitative pump and its control method

A technology of load sensitivity and control method, which is applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of large heat dissipation, large overflow loss of quantitative pump system, high set value, etc., and achieve reduction The effect of heat dissipation, reduction of overflow loss, and improvement of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

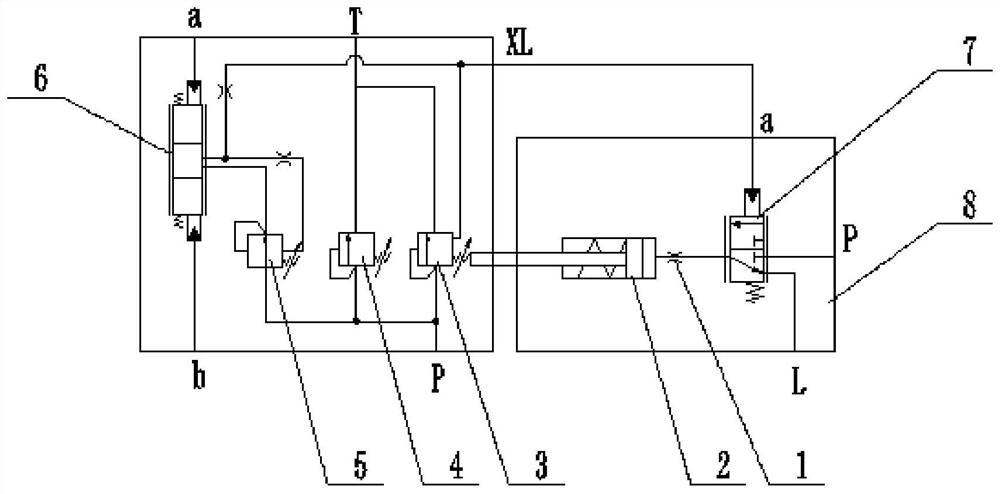

[0034] like figure 1 As shown, a new type of variable pressure differential load sensing system for quantitative pump includes load sensing valve 3, safety protection valve 4, pressure compensator 5, first reversing valve 6 and differential pressure control valve 8, load sensing valve 3, safety valve The oil inlet ends of the protection valve 4 and the pressure compensator 5 are both connected to the oil inlet, the load sensitive valve 3 is respectively connected to the differential pressure control mechanism 2 and the safety protection valve 4, and the pressure compensator 5 is connected to the first reversing valve 6;

[0035] The differential pressure control valve 8 includes a damping hole 1 , a differential pressure control mechanism 2 and a second reversing valve 7 . The differential pressure control mechanism 2 is connected to the second reversing valve 7 , and the differential pressure control mechanism 2 is connected to the second reversing valve 7 . There is a dampin...

Embodiment 2

[0045] like figure 1 As shown, a new type of variable pressure differential load sensing system for quantitative pump includes load sensing valve 3, safety protection valve 4, pressure compensator 5, first reversing valve 6 and differential pressure control valve 8, load sensing valve 3, safety valve The oil inlet ends of the protection valve 4 and the pressure compensator 5 are both connected to the oil inlet, the load sensitive valve 3 is respectively connected to the differential pressure control mechanism 2 and the safety protection valve 4, and the pressure compensator 5 is connected to the first reversing valve 6;

[0046] The differential pressure control valve 8 includes a damping hole 1 , a differential pressure control mechanism 2 and a second reversing valve 7 . The differential pressure control mechanism 2 is connected to the second reversing valve 7 , and the differential pressure control mechanism 2 is connected to the second reversing valve 7 . There is a dampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com