Novel lateral connector leachate inspection well

A leachate and inspection well technology, applied in the field of pipeline testing equipment, can solve the problems of poor acid and alkali corrosion resistance, long construction period, leakage, etc., and achieve the effects of strong acid and alkali corrosion resistance, simple construction and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]The specific embodiments of the present invention will be further described below in conjunction with the drawings. The same parts are indicated by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer" "Respectively refers to the direction toward or away from the geometric center of a particular component.

[0014]In order to make the content of the present invention easier to understand clearly, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

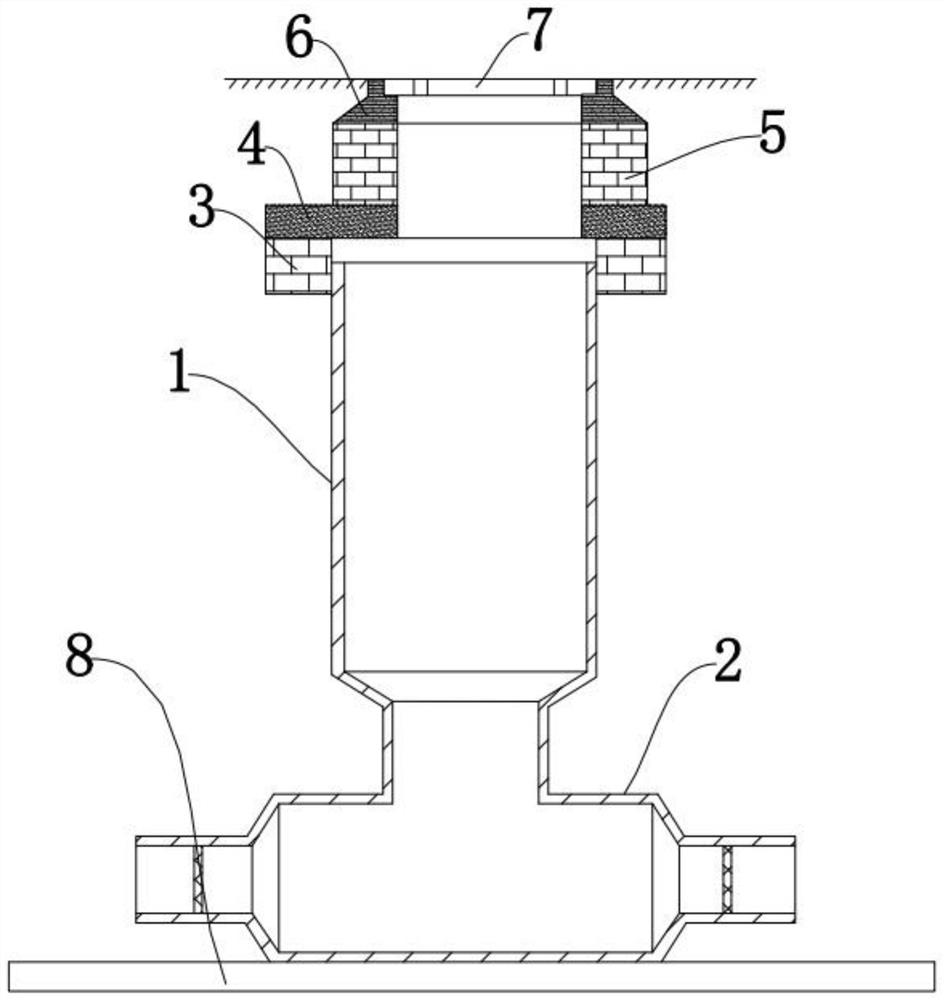

[0015]Such asfigure 1As shown, a new type of lateral interface leachate inspection well includes an HDPE pipe body 1, one end of the HDPE pipe body 1 is connected with a branch pipe 2 and the branch pipe 2 is buried undergr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com