Chemical production gas transfer drying device

A drying device, chemical production technology, applied in gas treatment, chemical instruments and methods, separation of dispersed particles, etc., can solve problems such as single drying method, poor drying effect, affecting the quality of gas drying, etc., to achieve good drying effect, Effect of improving drying quality and drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

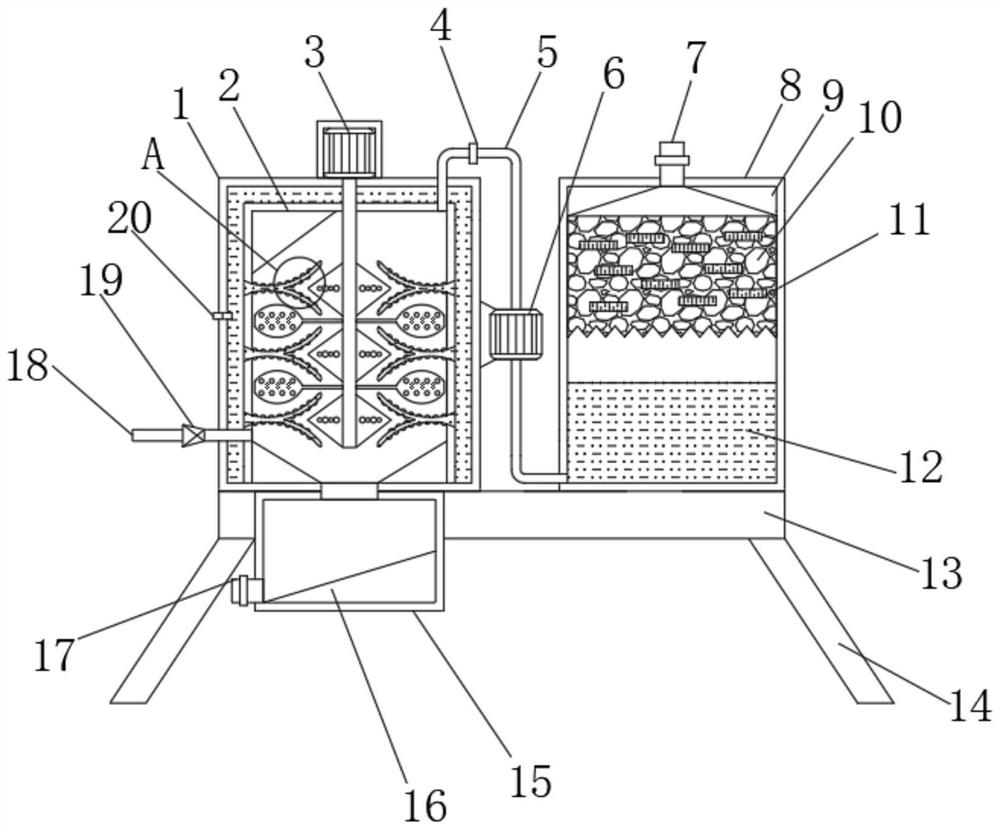

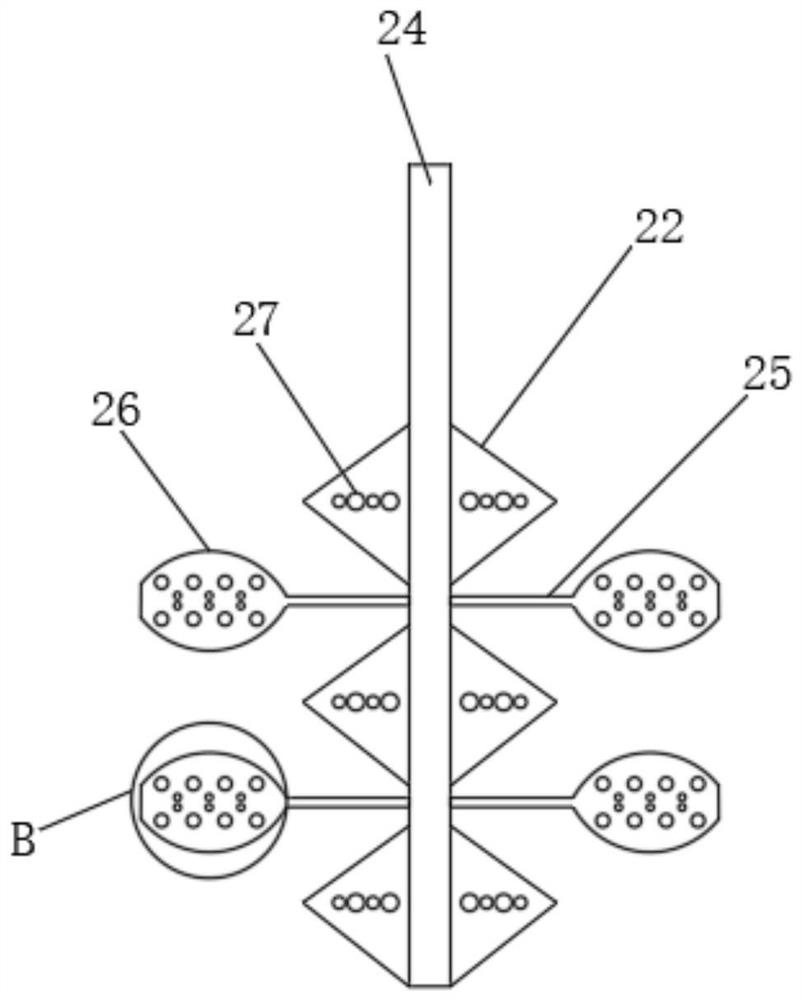

[0027] refer to Figure 1-5 , a chemical production gas transfer drying device, comprising a base 13, one side of the top outer wall of the base 13 is fixed with a first drying box 1 by screws, and the bottom inner wall of the first drying box 1 is provided with an inner cylinder 2, the first The gap between the drying box 1 and the inner cylinder 2 is provided with condensate, and the inner wall around the inner cylinder 2 is provided with through holes distributed equidistantly, and the inner wall of the through hole is inserted with a herringbone heat pipe 23, and the outer wall of the herringbone heat pipe 23 A heat conduction protrusion 21 is provided, and the top outer wall of the first drying box 1 is fixed with a motor 3 by screws, and the output shaft of the motor 3 is connected with a stirring mechanism through a coupling, and the other side of the top outer wall of the base 13 is fixed with a screw. The second drying box 8, and the bottom inner wall of the second dr...

Embodiment 2

[0036] refer to figure 1 , a gas transfer drying device for chemical production. Compared with Embodiment 1, this embodiment also includes an installation hole on the other side of the outer wall of the first drying box 1, and a semiconductor refrigeration chip 20 is inserted into the inner wall of the installation hole.

[0037] The hot gas conducts continuous heat exchange through the herringbone heat pipe 23. During the heat exchange, the temperature of the condensate will gradually rise. Can affect the drying process of the gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com