Wet dust collector for food processing workshop

A wet dust collector and food processing technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as hidden dangers, impact on workers' health and safety, rapid growth and reproduction of bacteria and microorganisms, etc., to ensure synchronization, work better

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

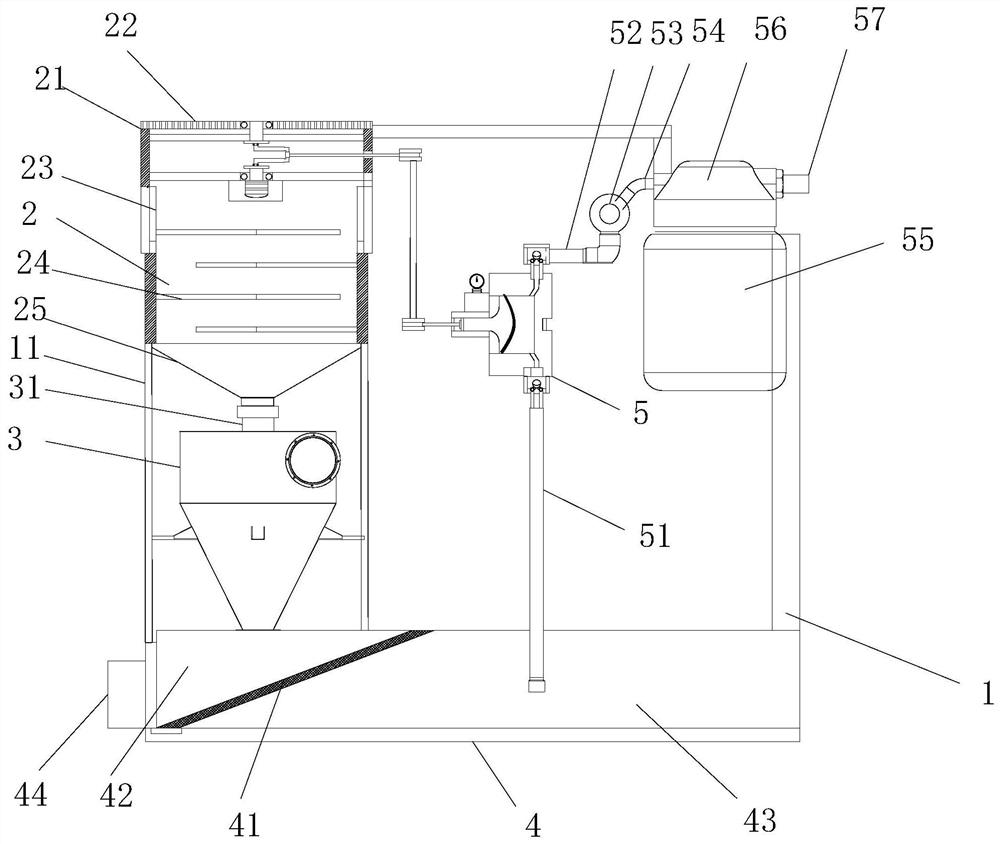

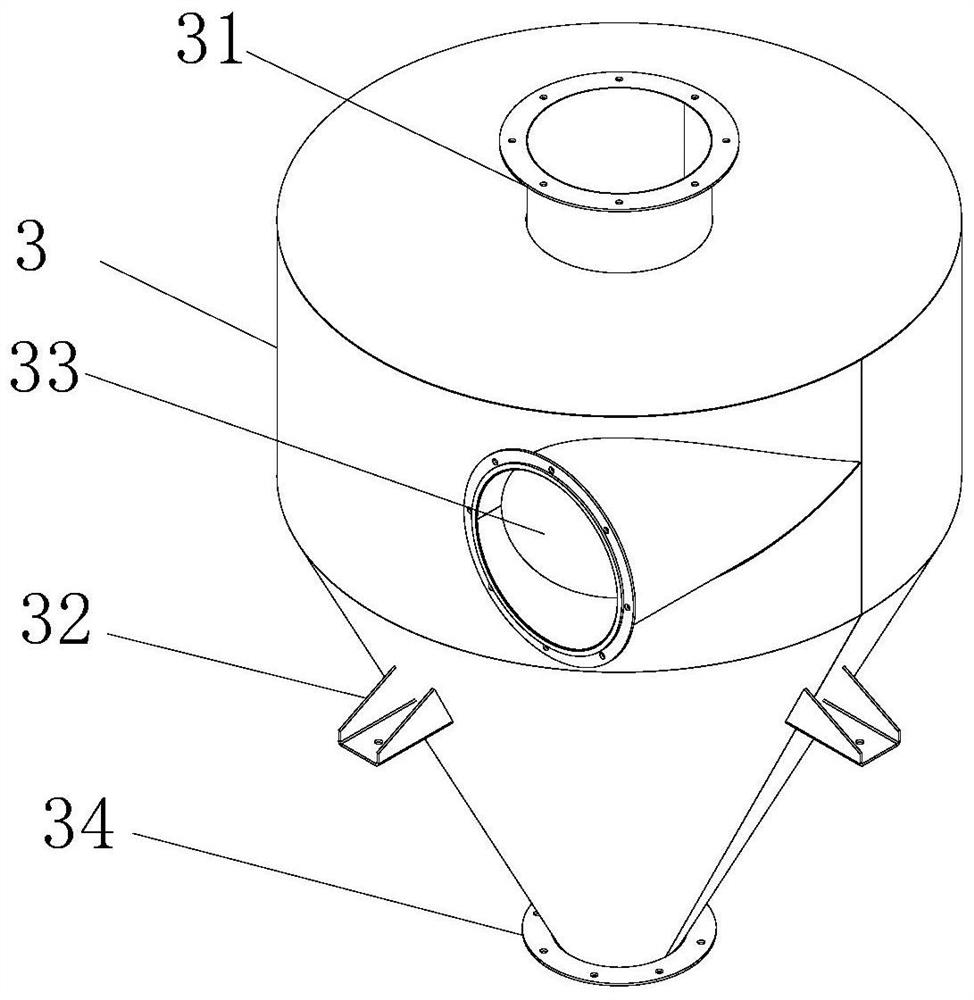

[0028] see figure 1 and figure 2 , a wet dust collector used in a food processing workshop, including a frame 1, a support frame 11 is arranged on the frame 1, and a dust suction tube 2 and a cyclone dust collector are respectively arranged on the upper and lower sides of the support frame 11 3. The bottom of the frame 1 is provided with a water tank 4 , and the other side of the frame 1 is also provided with a humidifier 55 .

[0029] The top of the dust suction tube 2 is provided with a dust suction cavity 21, and the top plate of the dust suction cavity 21 is provided with an air intake net cover 22, which will isolate the equipment from the external environment to a certain extent, so as to avoid external air pollution. Other non-dust objects fall into the vacuum tube 2 .

[0030] The bottom of the dust suction chamber 21 is provided with a dust-blocking cylinder 23, and several dust-blocking plates 24 are installed in the dust-blocking tube 23. Arranged, the bottom of...

Embodiment 2

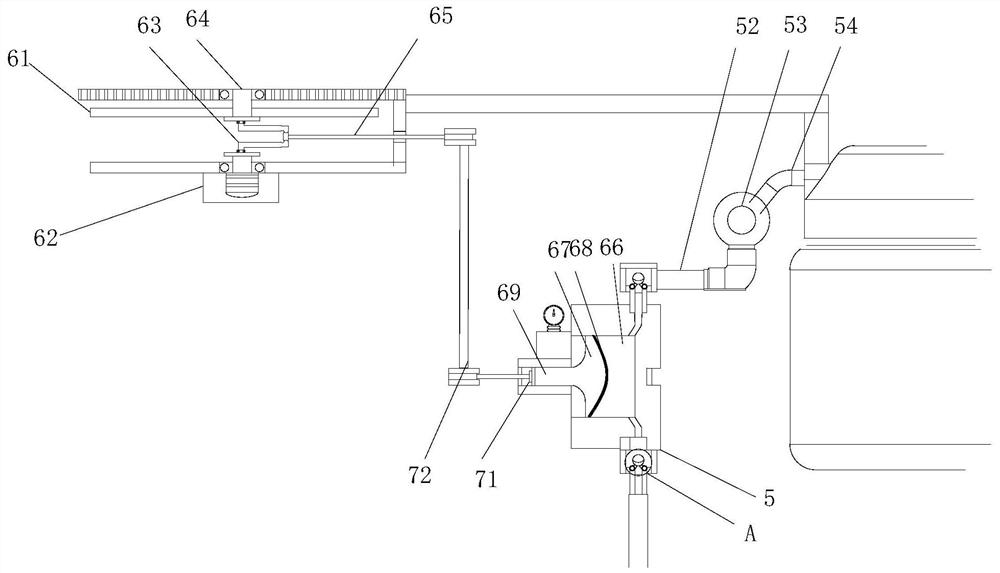

[0039] see figure 1 and image 3 , this embodiment is a further optimization of Embodiment 1. On the basis of it, the suction fan 61 is installed in the suction cavity 21, and the suction fan 61 is installed in the suction cavity 21 through a positioning bearing 64. The suction cavity The driving end of the fan 61 is provided with an initial fan 62 , and a crank rod 63 is arranged between the driving end of the initial fan 62 and the drainage fan 61 .

[0040] The water delivery chamber 5 is equipped with a built-in polymer membrane material 58, and the inside of the water delivery chamber 5 is divided into an air drum chamber 67 and a water delivery medium chamber 66 by the polymer membrane material 58, and the air drum chamber 67 is externally installed There is an air delivery cylinder 69, the said air delivery cylinder 69 has a built-in piston piece 71, said piston piece 71 is externally connected with an L-shaped piston rod 72, and said crank rod 63 is externally connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com