Synergistic spray charging and electrostatic dust collecting method and device

A charging device and electrostatic precipitator technology, which is applied in the field of electrostatic precipitator method and device for water mist charging and efficiency enhancement, can solve the problems of economic loss, large emission of soot concentration, and decrease in removal efficiency, so as to promote the growth of agglomeration and investment Low cost, enhanced viscous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

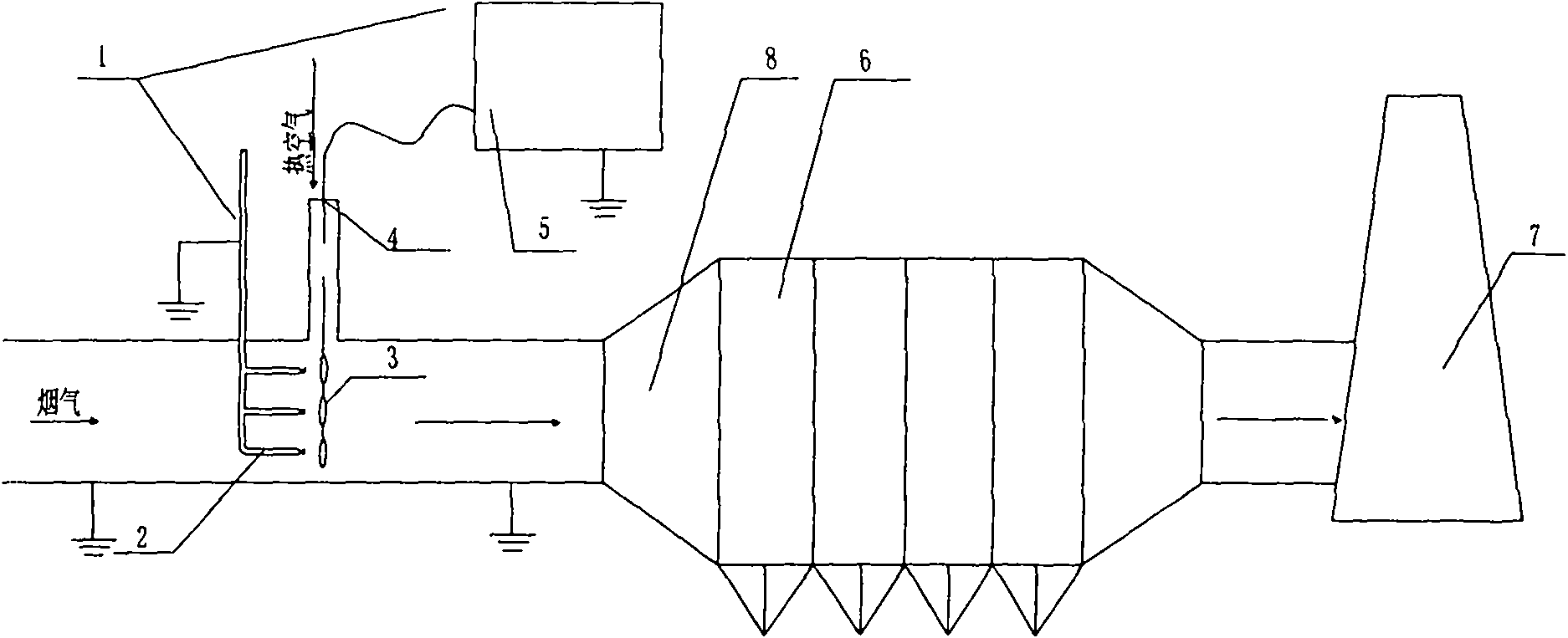

[0025] Embodiment 1: as figure 1 As shown, the water mist charging device 1 is installed on the flue in front of the entrance of the electrostatic precipitator 6, the flue gas discharged from the boiler first passes through the water mist charging device 1, and the droplets atomized by the two-fluid atomizing nozzle 2 pass through After the corona ring 3 powered by the high-voltage power supply 5, the charge is rapidly induced, and the charged liquid droplets containing the agglomerating agent are sprayed into the flue gas; the charged liquid droplets are fully in contact with the flue gas: on the one hand, the charged liquid droplets can The flue gas is humidified, cooled and tempered, wherein the relative humidity is between 50%-80%, and the temperature is between 70-80°C; on the other hand, the charged liquid droplets containing agglomerating agents collide with the dust particles to form After wetting the particles, the viscous force and Coulomb force between the particles...

Embodiment 2

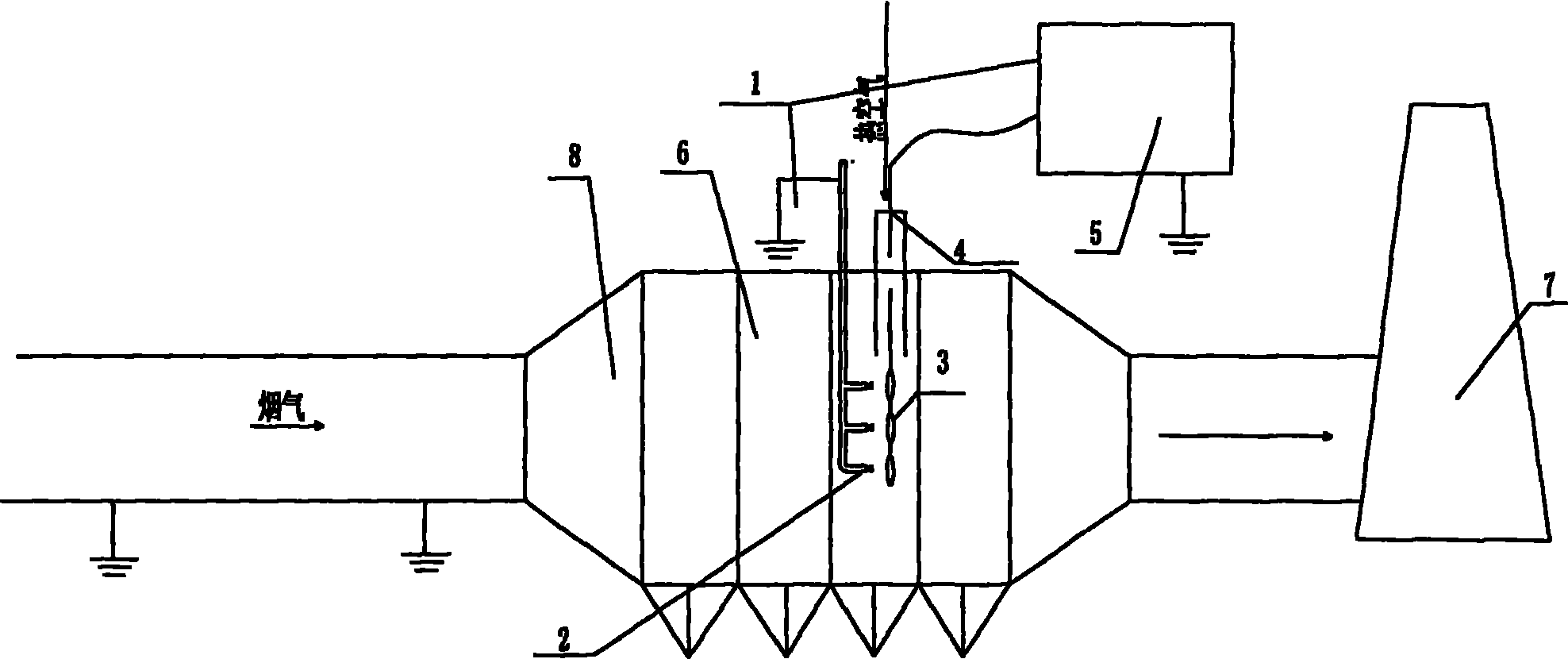

[0030] Embodiment 2: The difference from Embodiment 1 is that the water mist charging device 1 is installed in the inlet diverging section 8 of the electrostatic precipitator, and the rest are the same and will not be repeated here.

Embodiment 3

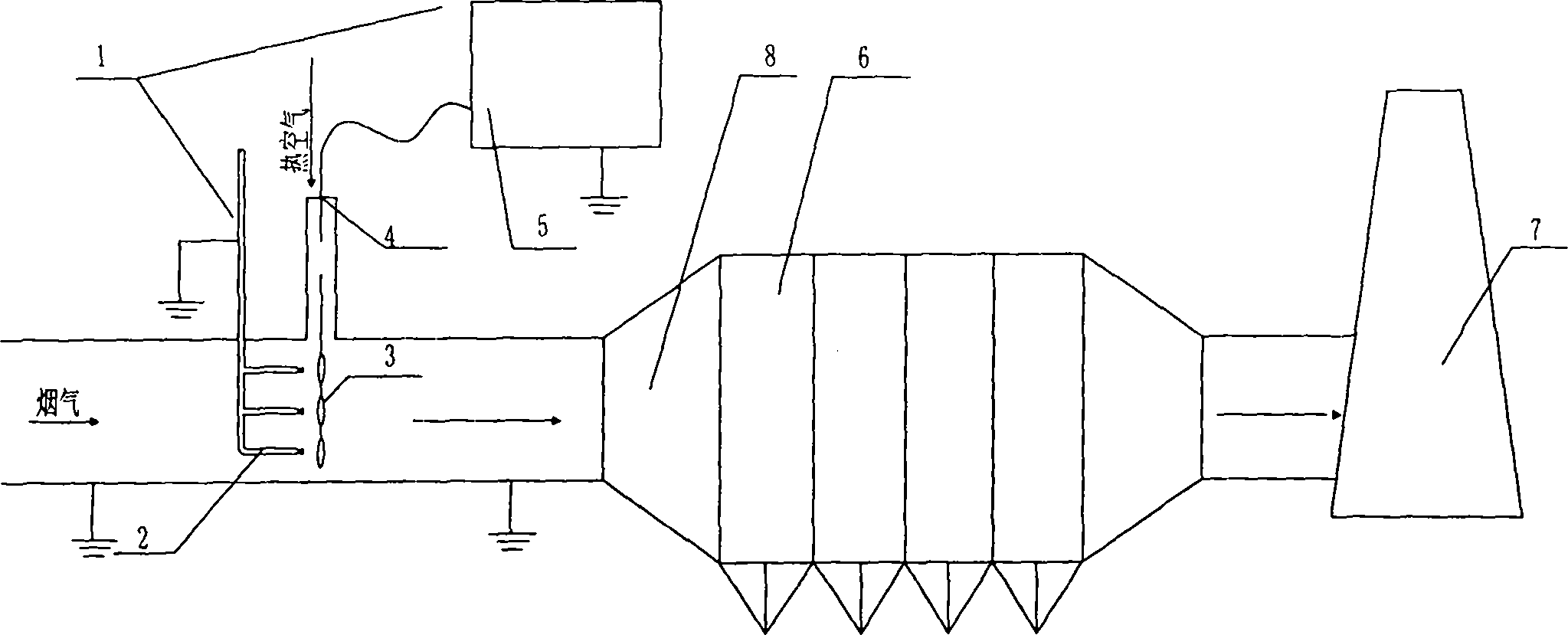

[0031] Embodiment 3: As shown in Figure 3, the electrostatic precipitator has four levels of electric fields, remove the penultimate electric field in the electrostatic precipitator, and install the water mist charging device at the position of this level of electric field; the flue gas discharged from the boiler is first Through the first and second electric fields of the electrostatic precipitator 6, large dust particles in the flue gas are removed;

[0032] The remaining fine dust particles pass through the water mist charging device 1 installed in the third-level electric field, and the water mist charging device 1 sprays charged droplets containing agglomerating agents into the flue gas, and the charged droplets fully contact with the flue gas : On the one hand, the charged liquid droplets can humidify, cool and temper the flue gas, wherein the relative humidity is between 50%-80%, and the temperature is between 70-80°C; on the other hand, the After the charged liquid dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com