Method and device for fume purification treatment in waste incineration

A flue gas purification and treatment method technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve problems such as substandard flue gas emissions, and achieve the effects of low operating cost, convenient operation and management, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

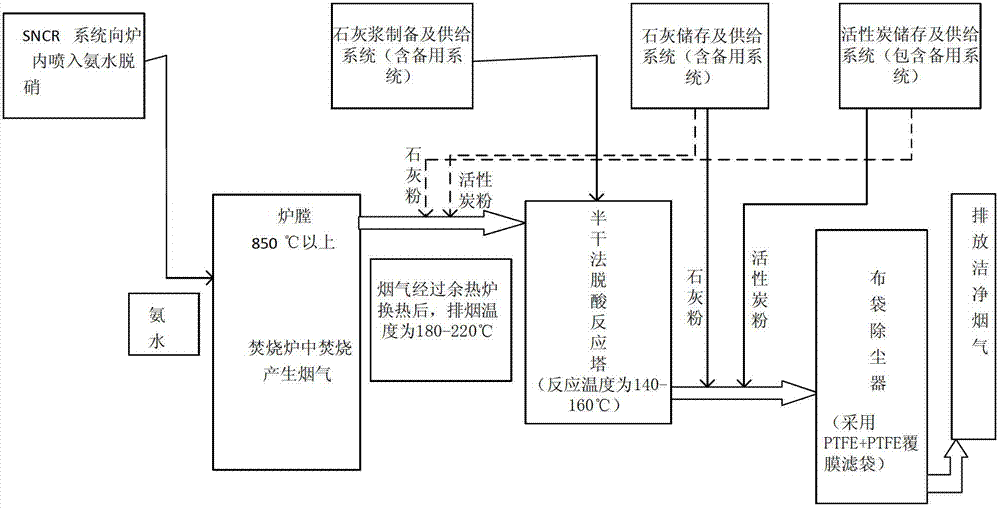

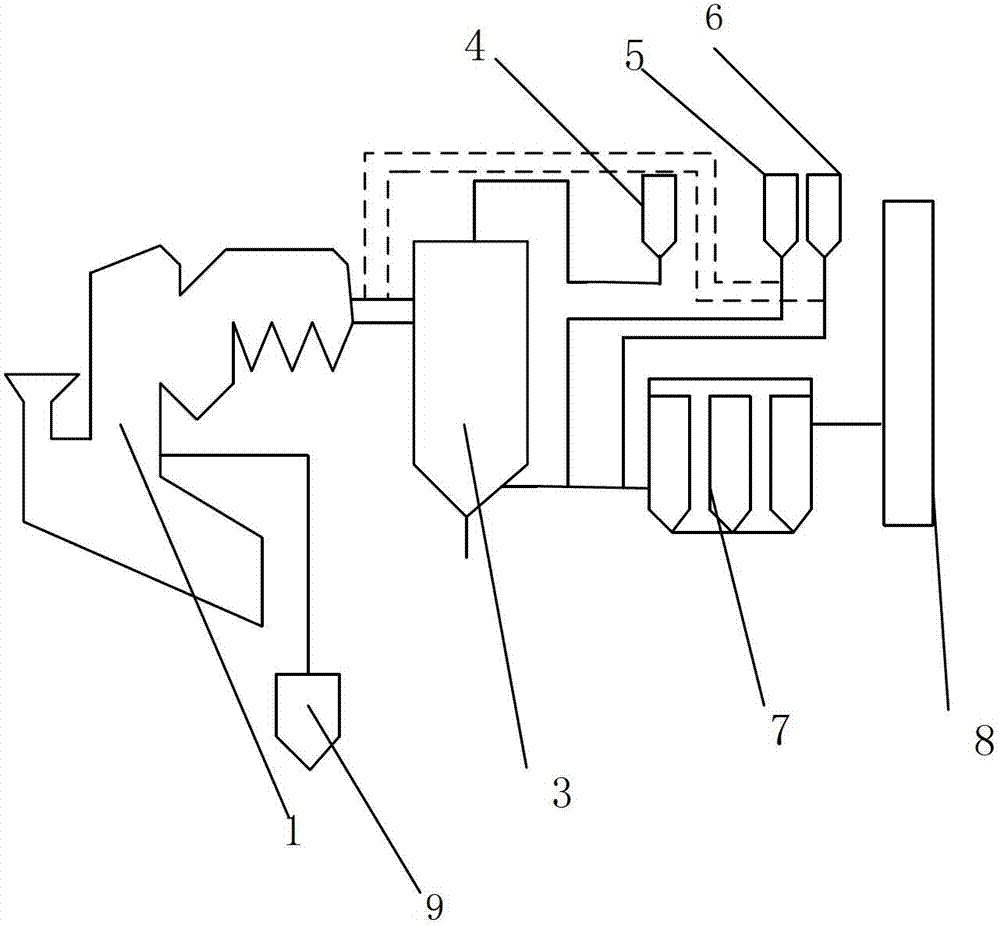

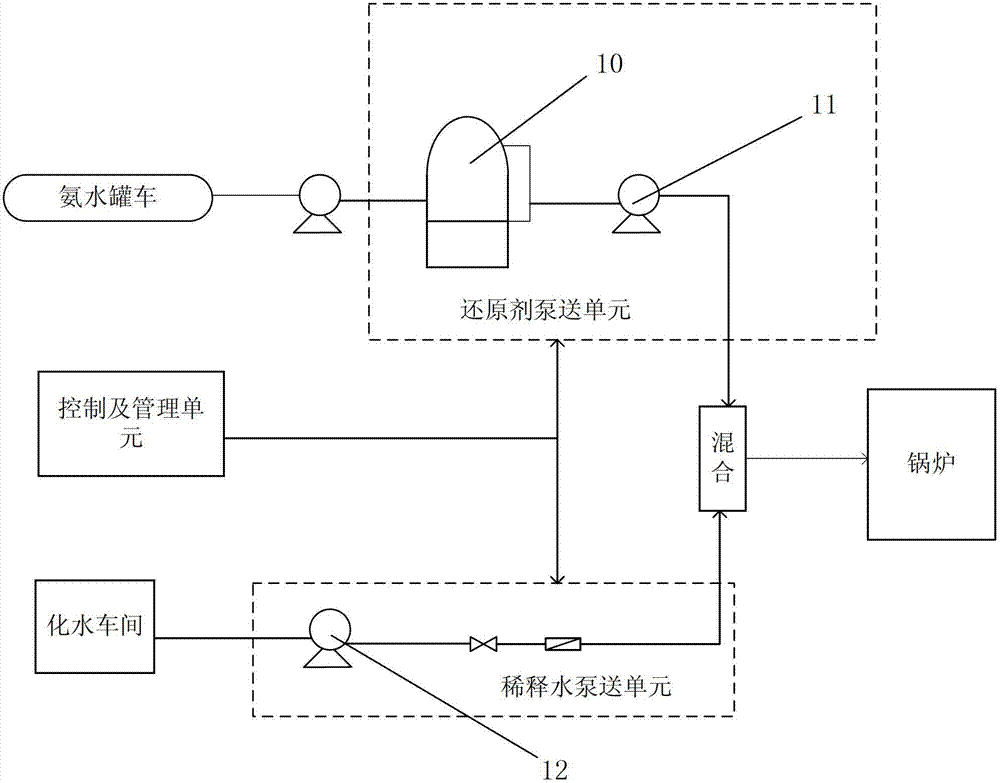

[0030] During the normal operation of the waste incinerator, it produces toxic and harmful substances such as acidic substances, dioxins, dust, etc., and the flue gas needs to be purified before it can be discharged into the atmosphere. The method of the present invention comprises 5 steps of denitrification, semi-dry deacidification, dry deacidification, activated carbon adsorption and bag dust removal, and the treatment process is as follows:

[0031] During the design and operation of the boiler, the temperature of the furnace is guaranteed to be above 850°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com