Manufacturing process of FF touch screen

A production process and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of high product cost, low yield, cumbersome printing and processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

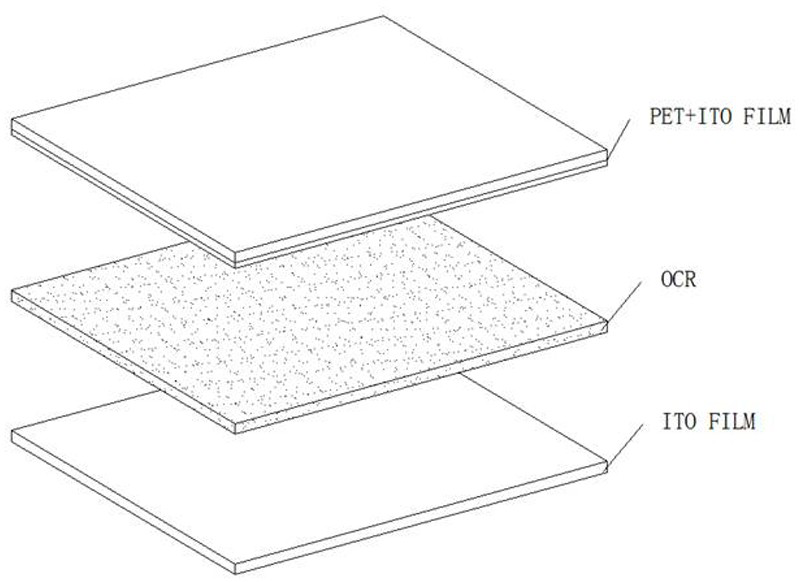

[0027] A manufacturing process of an FF touch screen, comprising the following steps:

[0028] (1) First, electroplate or coat a layer of ITO conductive layer on the back of the PET material as the upper conductive material of the touch screen;

[0029] (2) The ITO conductive layer on the back of the PET material is etched with a preset conductive pattern and circuit by a laser etching machine;

[0030] (3) Then surface treatment is carried out on the front of the PET material, so that the surface hardness of the PET material reaches above 3H, and can support human finger touch writing;

[0031] (4) Finally, the conductive surface of the ITO film on the middle and lower layers of the touch screen is facing upwards, and the middle is bonded with transparent optical adhesive OCA, so that an FF touch screen with a cover effect can be formed.

[0032] The raw materials of the PET material in the step (1) include the following components by weight: 70 parts of PET, 6 parts of glas...

Embodiment 2

[0037] A manufacturing process of an FF touch screen, comprising the following steps:

[0038] (1) First, electroplate or coat a layer of ITO conductive layer on the back of the PET material as the upper conductive material of the touch screen;

[0039] (2) The ITO conductive layer on the back of the PET material is etched with a preset conductive pattern and circuit by a laser etching machine;

[0040] (3) Then surface treatment is carried out on the front of the PET material, so that the surface hardness of the PET material reaches above 3H, and can support human finger touch writing;

[0041] (4) Finally, the conductive surface of the ITO film on the middle and lower layers of the touch screen is facing upwards, and the middle is bonded with transparent optical adhesive OCA, so that an FF touch screen with a cover effect can be formed.

[0042] The raw material of PET material in the step (1) comprises the following components by weight: 80 parts of PET, 70 parts of glass fi...

Embodiment 3

[0047] A manufacturing process of an FF touch screen, comprising the following steps:

[0048] (1) First, electroplate or coat a layer of ITO conductive layer on the back of the PET material as the upper conductive material of the touch screen;

[0049] (2) The ITO conductive layer on the back of the PET material is etched with a preset conductive pattern and circuit by a laser etching machine;

[0050] (3) Then surface treatment is carried out on the front of the PET material, so that the surface hardness of the PET material reaches above 3H, and can support human finger touch writing;

[0051] (4) Finally, the conductive surface of the ITO film on the middle and lower layers of the touch screen is facing upwards, and the middle is bonded with transparent optical adhesive OCA, so that an FF touch screen with a cover effect can be formed.

[0052] The raw materials of the PET material in step (1) include the following components by weight: 90 parts of PET, 10 parts of glass f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com