Laser quenching light-absorbing coating and preparation method thereof

A light-absorbing coating and laser quenching technology, which is applied to radiation-absorbing coatings, shellac coatings, coatings, etc., can solve the problems of complex preparation process, high price, environmental pollution, etc., and achieve simple preparation process, high absorption rate, and reduced The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

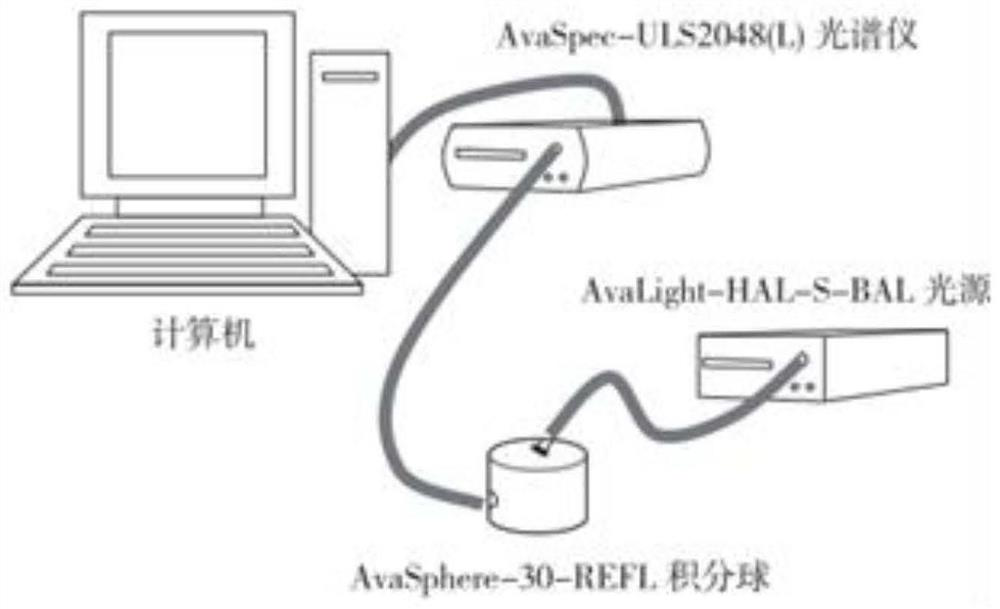

Image

Examples

Embodiment 1

[0050] The preparation method of the light-absorbing coating for laser surface heat treatment comprises the following steps:

[0051] Step 1: Put the binder: 10.0g into an ordinary beaker, add anhydrous alcohol: 20mL, and stir by hand until the binder is completely dissolved;

[0052] Step 2: Add wetting agent: 0.5g; leveling aid: 1.2g to the solution in Step 1, stir while adding, and stir by hand until it is completely dissolved;

[0053] Step 3: Add anti-settling agent: 0.4g; thickener: 0.2g; diluent: 6.0mL; dispersant: 0.02g into the solution of step 2 in turn, and stir it evenly by hand;

[0054] Step 4: Add 100 mL of distilled water into the solution of Step 3, stir with a magnetic stirrer, the rotor speed is 12r / s, the stirring time is 60min, and the stirring is uniform;

[0055] Step 5: Add 4.0g of nano-alumina and nano-silicon dioxide into the solution of step 4, the nano-alumina is 3.0g, the nano-silica is 1.0g, stir with a magnetic stirrer, the rotor speed is 12r / s, a...

Embodiment 2

[0059] The preparation method of the light-absorbing coating for laser surface heat treatment comprises the following steps:

[0060] Step 1: Put the binder: 10.0g into an ordinary beaker, add anhydrous alcohol: 20mL, and stir by hand until the binder is completely dissolved;

[0061] Step 2: Add wetting agent: 0.5g; leveling aid: 1.2g to the solution in step 1, stir while adding, and stir manually until completely dissolved;

[0062] Step 3: Add anti-settling agent: 0.4g; thickener: 0.2g; diluent: 6.0mL; dispersant: 0.02g into the solution of step 2 in turn, and stir evenly by hand;

[0063] Step 4: Add 100 mL of distilled water into the solution of Step 3, stir with a magnetic stirrer, the rotor speed is 12r / s, the stirring time is 60min, and the stirring is uniform;

[0064] Step 5: Add 4.0g of nano-alumina and nano-silica into the solution of step 4, the nano-alumina is 2.0g, and the nano-silica is 2.0g, stir with a magnetic stirrer, the rotor speed is 12r / s, and the stir...

Embodiment 3

[0068] The preparation method of the light-absorbing coating for laser surface heat treatment comprises the following steps:

[0069] Step 1: Put the binder: 10.0g into an ordinary beaker, add anhydrous alcohol: 20mL, and stir by hand until the binder is completely dissolved;

[0070] Step 2: Add wetting agent: 0.5g; leveling aid: 1.2g to the solution in step 1, stir while adding, and stir manually until completely dissolved;

[0071] Step 3: Add anti-settling agent: 0.4g; thickener: 0.2g; diluent: 6.0mL; dispersant: 0.02g into the solution of step 2 in turn, and stir evenly by hand;

[0072] Step 4: Add 100 mL of distilled water to the solution mixed in step 3, stir with a magnetic stirrer, the rotor speed is 12r / s, the stirring time is 60min, and the stirring is uniform;

[0073] Step 5: Add 4.0g of nano-alumina and nano-silica into the solution of step 4, the nano-alumina is 1.0g, and the nano-silica is 3.0g, stir with a magnetic stirrer, the rotor speed is 12r / s, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com