Height-adjustable air dryer bushing press-fitting device

A technology of air dryer and press-fitting device, which is applied in the field of press-fitting devices, can solve the problems such as the inability to adjust the press-fitting depth, and achieve the effect of simple and reliable structure, high assembly efficiency, and guaranteed consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

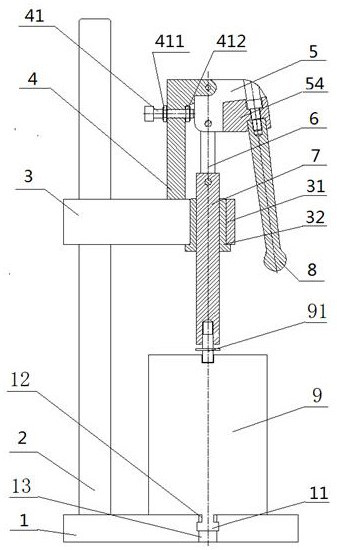

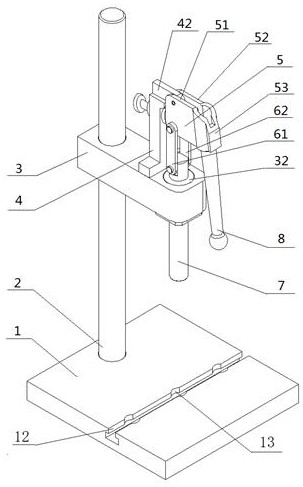

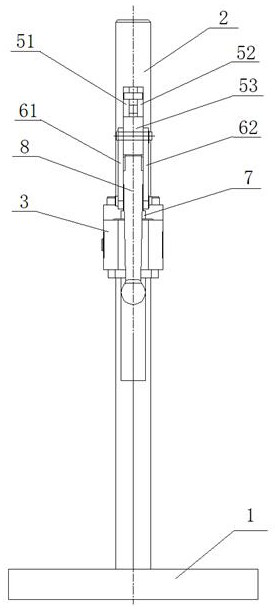

[0064] see Figure 1 to Figure 5 , a height-adjustable air dryer liner press-fitting device includes a base plate base 1, a height support 2 and a hand pressing device, the height support 2 is vertically connected to the base plate base 1, and the hand pressing device is fixed Connected to the middle part of the height support 2; the hand pressing device includes a guide connecting plate 3, a support base 4, a flip pressing plate 5, a pressing connecting rod 6, a moving pressing rod 7 and a handle 8, and the guide connecting plate 3 One end is vertically connected with the middle part of the height bearing 2, the other end of the guide connecting plate 3 is slidingly matched with the moving pressure bar 7, and the top of the guide connecting plate 3 is vertically connected with the bottom of the support support 4, and the support support 4 is located at the height Between the bearing 2 and the moving pressure bar 7, the side of the supporting base 4 close to the moving pressur...

Embodiment 2

[0066] Embodiment 2 basic content is the same as embodiment 1, and its difference is:

[0067] The screw rod of the limit bolt 41 passes through the limit nut 411, the support base 4 and the self-locking nut 412 successively, and cooperates with the overturning pressure plate 5 in a limited position. threaded fit; the overturning platen 5 includes a connecting plate 53 and a symmetrically arranged first side plate 51 and a second side plate 52, the two sides of the connecting plate 53 are respectively connected to the first side plate 51 and the second side plate 52 The side part is fixedly connected; the support base 4 is provided with a connecting frame 42, one end of the connecting frame 42 is fixedly connected with the top of the supporting base 4, and the other end of the connecting frame 42 is located between the first side plate 51 and the second side plate. Between the side plates 52; the press-down link 6 includes a first press-down link 61 and a second press-down lin...

Embodiment 3

[0069] Embodiment 3 basic content is the same as embodiment 2, and its difference is:

[0070]The bush installation position 71 matches one end of the air dryer exhaust pipe bush 91 to be press-fitted, and the top of the air dryer main body 9 is provided with the other end of the air dryer exhaust pipe bush 91. The matching air outlet hole 92, the bottom of the air dryer main body 9 is provided with a circular bump 93, the bump 93 is inserted into the through hole 13, and the bottom of the bump 93 is provided with a lag bolt 94, square Head bolt 94 comprises square screw head 95 and threaded rod of integral structure, and described square screw head 95 is located in guide groove 11, and the width of square screw head 95 matches the width of guide groove 11, and the upper surface of square screw head 95 Cooperate with the stopper 12 in a limited position, the square screw head 95 slides with the guide groove 11 , the threaded rod of the lag bolt 94 passes through the protrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com