Microwave plasma torch ignition method

A microwave plasma, microwave technology, applied in the direction of plasma, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

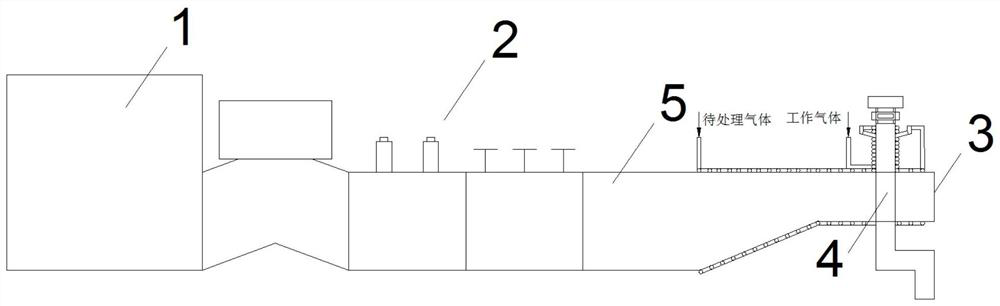

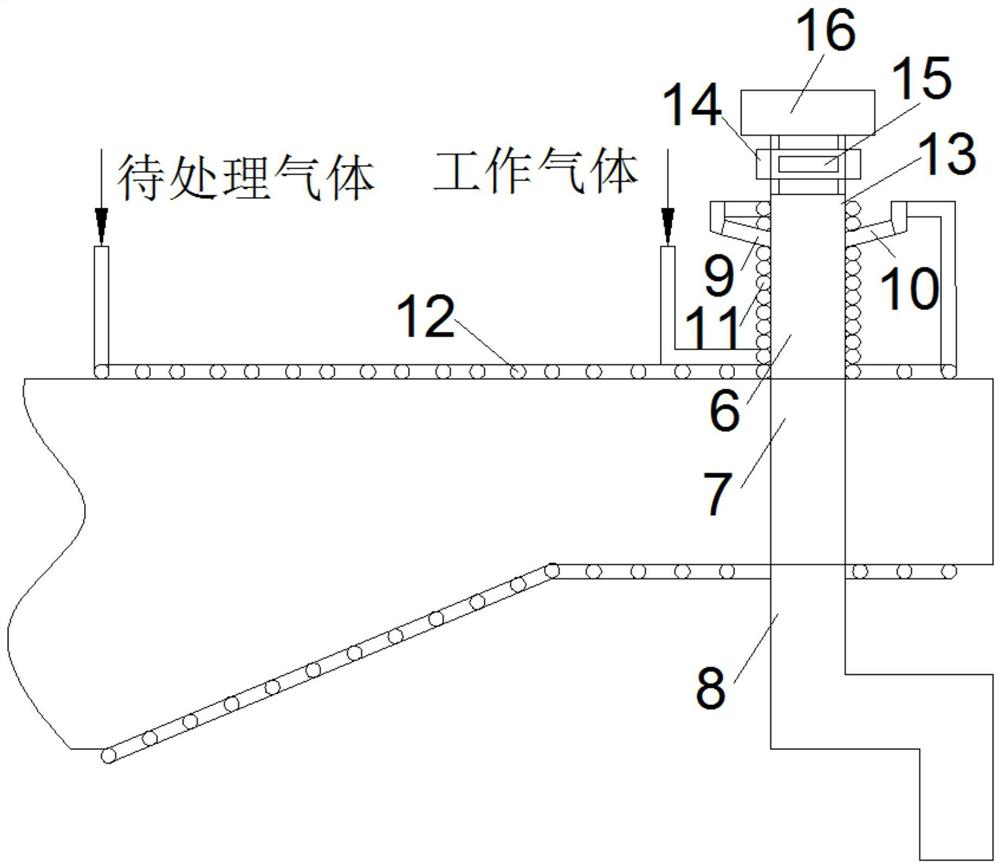

[0021] See attached Figure 1~2 . A microwave plasma torch ignition method, using a microwave plasma torch; the microwave plasma torch includes a microwave generator 1, a microwave delivery device 2, a shielding shell 3 and a discharge tube 4; the discharge tube 4 runs through the shielding shell 3; The shielding shell 3 is provided with a feed port; the feed port is used to receive the microwave input from the microwave generator 1 through the microwave delivery device 2; the discharge tube 4 is used to input the working gas and receive the microwave input from the feed port; The microwave generator 1 has at least a pulse wave mode of operation and a continuous wave mode of operation; comprising the following steps:

[0022] Step S10, inputting working gas into the discharge tube 4;

[0023] Step S20, the microwave generator 1 is turned on, and the working mode is set to the pulse wave working mode, and the microwave generator 1 inputs pulse waves to the working gas in the ...

Embodiment 2

[0027] See attached Figure 1~2 . A microwave plasma torch ignition method, using a microwave plasma torch; the microwave plasma torch includes a microwave generator 1, a microwave delivery device 2, a shielding shell 3 and a discharge tube 4; the discharge tube 4 runs through the shielding shell 3; The shielding shell 3 is provided with a feed port; the feed port is used to receive the microwave input from the microwave generator 1 through the microwave delivery device 2; the discharge tube 4 is used to input the working gas and receive the microwave input from the feed port; The microwave generator 1 has at least a pulse wave mode of operation and a continuous wave mode of operation; comprising the following steps:

[0028] Step S10, inputting working gas into the discharge tube 4;

[0029] Step S20, the microwave generator 1 is turned on, and the working mode is set to the pulse wave working mode, and the microwave generator 1 inputs pulse waves to the working gas in the ...

Embodiment 3

[0034] See attached Figure 1~2 . A microwave plasma torch ignition method, using a microwave plasma torch; the microwave plasma torch includes a microwave generator 1, a microwave delivery device 2, a shielding shell 3 and a discharge tube 4; the discharge tube 4 runs through the shielding shell 3; The shielding shell 3 is provided with a feed port; the feed port is used to receive the microwave input from the microwave generator 1 through the microwave delivery device 2; the discharge tube 4 is used to input the working gas and receive the microwave input from the feed port; The microwave generator 1 has at least a pulse wave mode of operation and a continuous wave mode of operation; comprising the following steps:

[0035] Step S10, inputting working gas into the discharge tube 4;

[0036] Step S20, the microwave generator 1 is turned on, and the working mode is set to the pulse wave working mode, and the microwave generator 1 inputs pulse waves to the working gas in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com