Method for detecting swelling capacity of starch particles in gelatinization process based on computer vision

A technology of computer vision and starch granules, applied in computing, image data processing, instruments, etc., can solve the problems of long detection time, poor threshold range effect, time-consuming cost, etc., to reduce the cost of selection time and shorten the time-consuming , Improve the filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Such as Figure 7 Shown, a kind of starch granule swelling ability detection method based on computer vision process, comprises the following steps:

[0076] (1) Preparation of glass slides: 0.07 g of lentil starch was weighed and mixed with 10 ml of water to prepare a lentil starch suspension with a mass ratio of starch to water of 7%. Mix well, use a pipette, and on the basis of mixing, absorb the starch suspension and add it dropwise to the center of the circular glass slide. After the starch suspension is dispersed, seal it with a cover glass and glass glue. Wherein after sealing, the starch suspension should be uniformly dispersed and there should be intervals between starch granules.

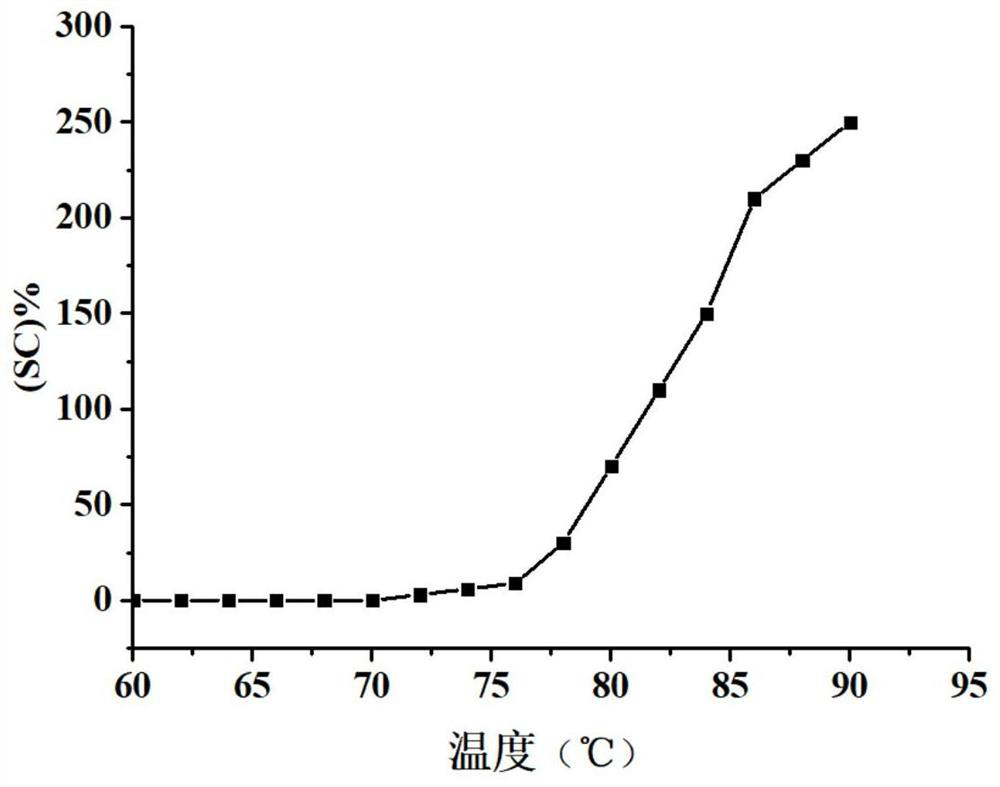

[0077] (2) Photo recording: Place the glass slide of the lentil starch suspension that has been sealed on the hot stage equipment (THMS600, Linkam, UK), heat up, adjust the starch granule image to an appropriate position, adjust the microscope so that the eyepiece is 10 times, The...

Embodiment 2

[0111] A method for detecting swelling capacity of starch granules in gelatinization process based on computer vision, comprising the steps of:

[0112] (1) Preparation of glass slides: 0.10 g of potato starch was weighed and mixed with 10 ml of water to prepare a potato starch suspension with a mass ratio of starch to water of 1%. Mix well, use a pipette, and on the basis of mixing, absorb the starch suspension and add it dropwise to the center of the circular glass slide. After the starch suspension is dispersed, seal it with a cover glass and glass glue. Wherein after sealing, the starch suspension should be uniformly dispersed and there should be a certain interval between the starch granules.

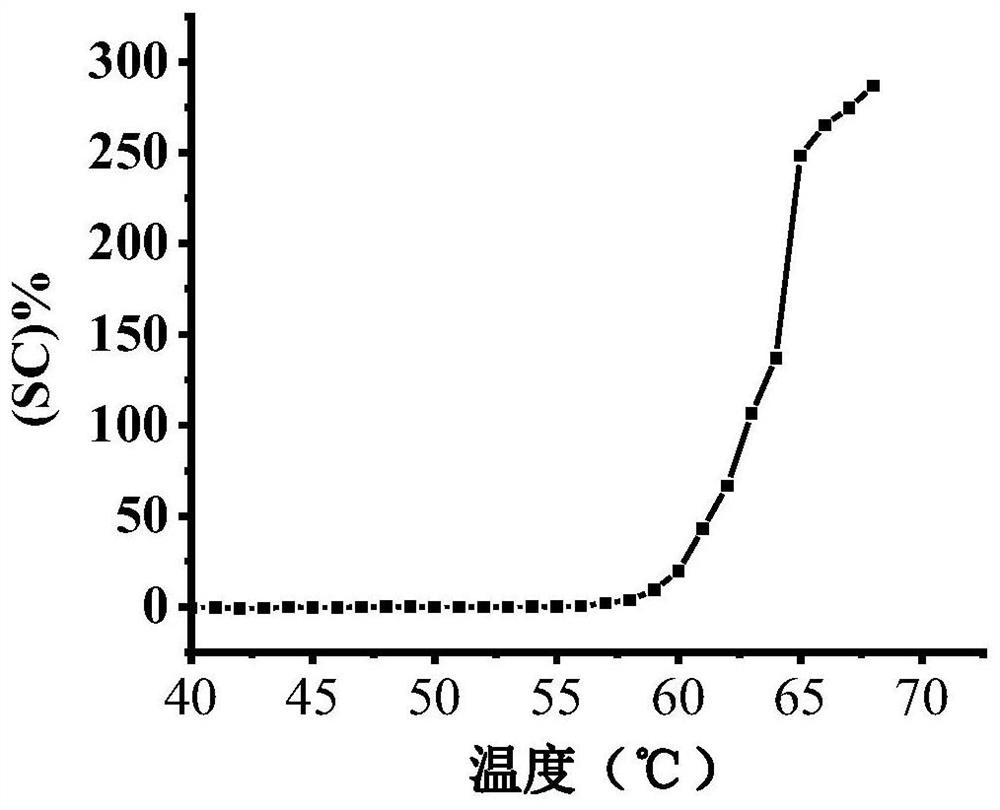

[0113] (2) Photo recording: Place the glass slide of the sealed potato starch suspension on the hot stage equipment (THMS600, Linkam, UK), heat up, adjust the starch granule image to an appropriate position, adjust the microscope so that the eyepiece is 10 times, The objective len...

Embodiment 3

[0143] A method for detecting swelling capacity of starch granules in gelatinization process based on computer vision, comprising the steps of:

[0144] (1) Preparation of glass slides: Weigh 0.05 g of cornstarch, mix it with 10 ml of water, and prepare a cornstarch suspension with a mass ratio of cornstarch to water of 0.5%. Mix well, use a pipette, and on the basis of mixing, absorb the cornstarch suspension and add it dropwise to the center of the circular glass slide. After the cornstarch suspension is dispersed, seal it with a cover glass and glass glue. Wherein after sealing, the starch suspension should be uniformly dispersed and there should be a certain interval between the starch granules.

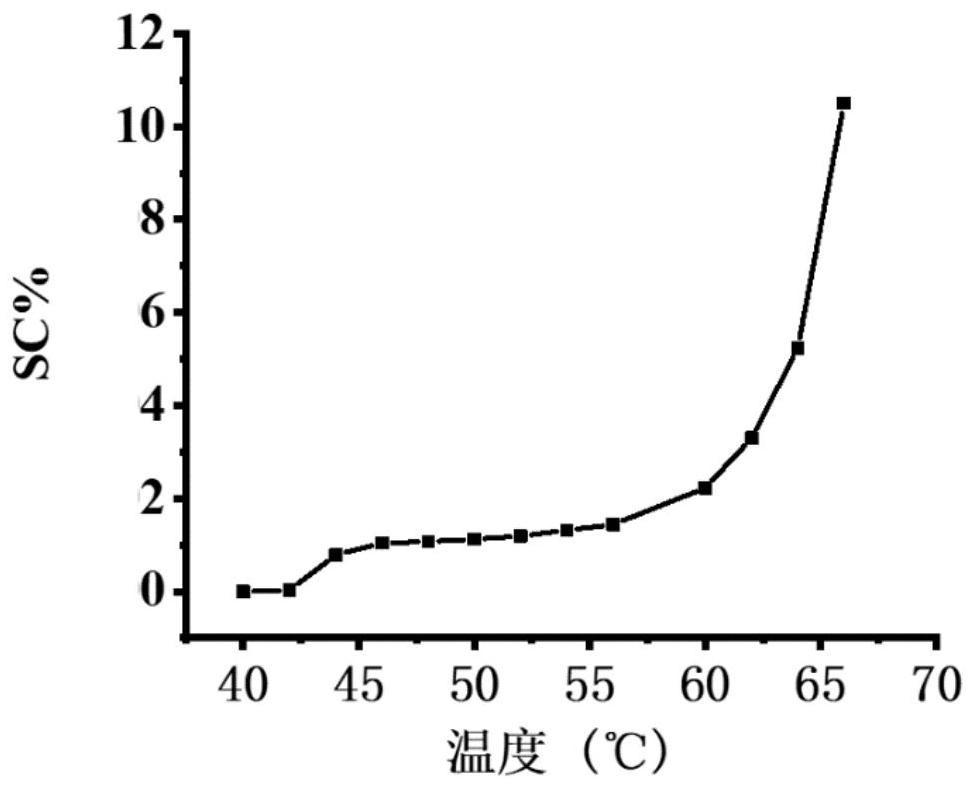

[0145] (2) Photo recording: Place the glass slide of the sealed corn starch suspension on the hot stage equipment (THMS600, Linkam, UK), heat up, adjust the starch granule image to an appropriate position, adjust the microscope so that the eyepiece is 10 times, The objective len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com