Fault tracing method in lithium ion battery production process

A lithium-ion battery, production process technology, applied in program control, electrical testing/monitoring, instruments, etc., can solve the problem of difficult to guarantee the stability of diagnostic performance, the interpretability of complex models, and the inability to obtain fault causality and influencing variables, etc. problems to achieve good interpretability and acceptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention are described below with reference to the accompanying drawings. Those skilled in the art should understand that these embodiments are only used to explain the technical principles of the present invention, and are not intended to limit the protection scope of the present invention.

[0037] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

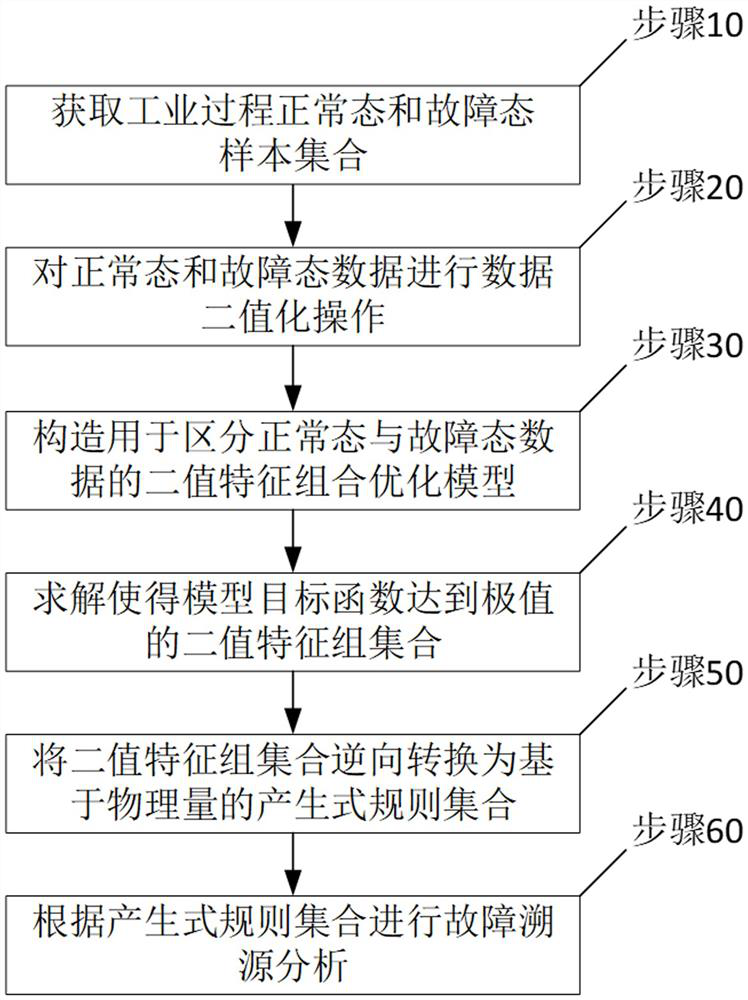

[0038] The invention provides an industrial process fault tracing method based on binarized feature combination optimization. Such as figure 1 As shown, the method includes the following steps:

[0039] Step 10: Obtain a sample set of normal state and fault state of the industrial process;

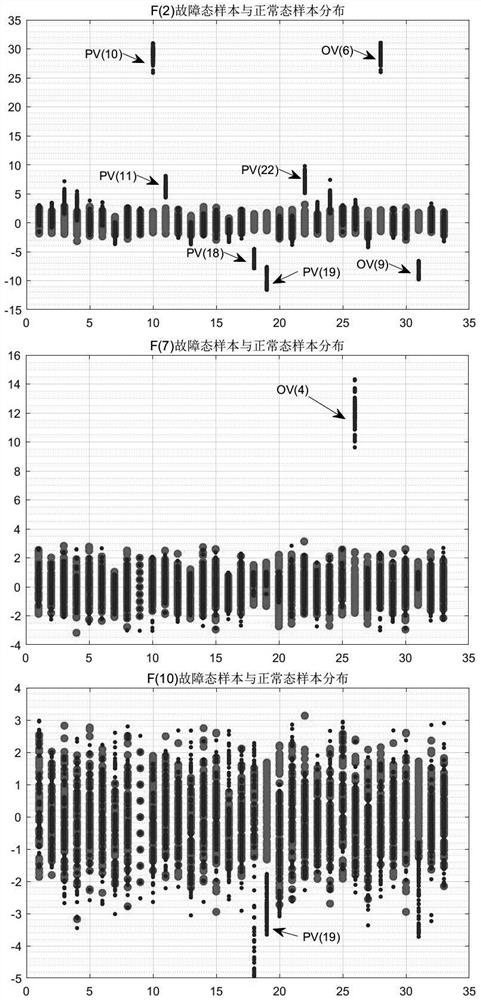

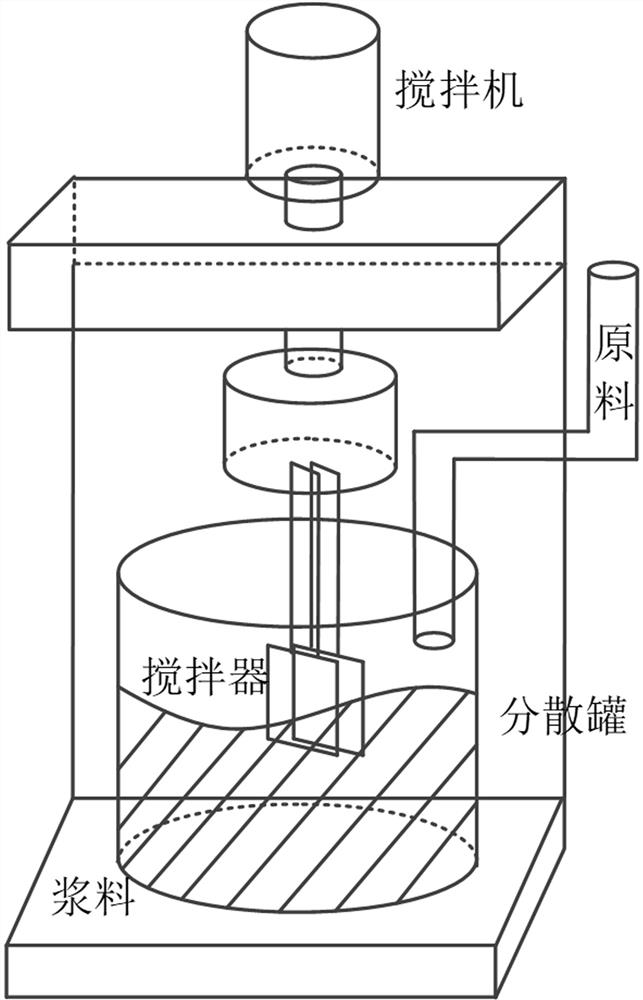

[0040] The normal state and fault state samples in the step 10 include main physical quantities that can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com