Combined gearbox

A gearbox and combined technology, applied in the field of transmission, can solve the problems of large space occupation, bulky overall structure, inability to use feeders, etc., and achieve the effect of convenient and reliable speed change, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the specific embodiments and drawings, but the specific embodiments do not limit the present invention in any way.

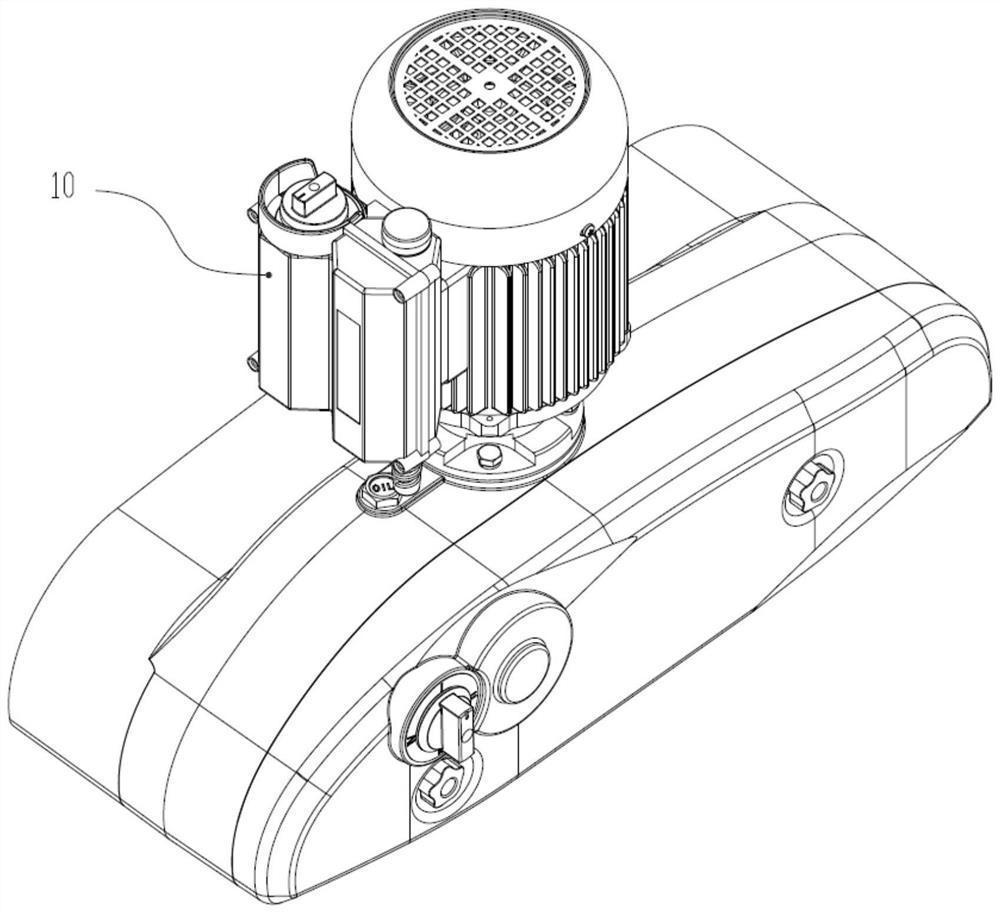

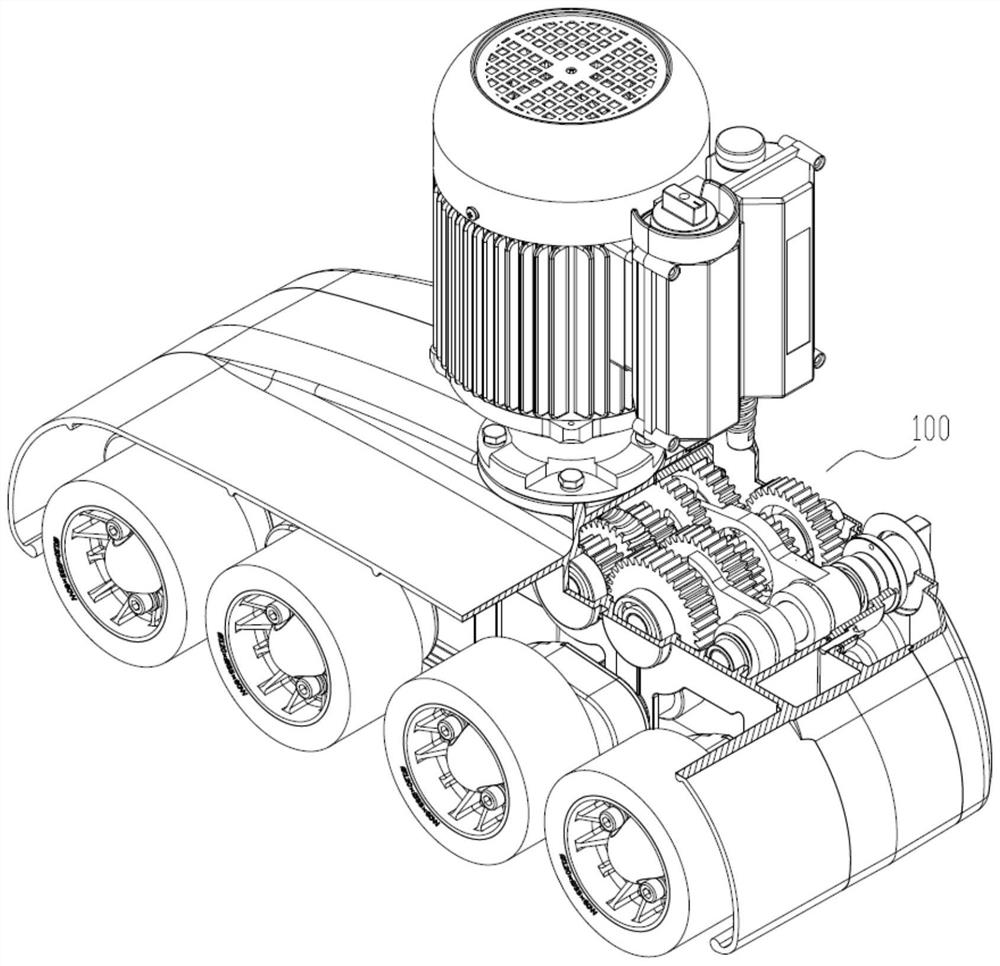

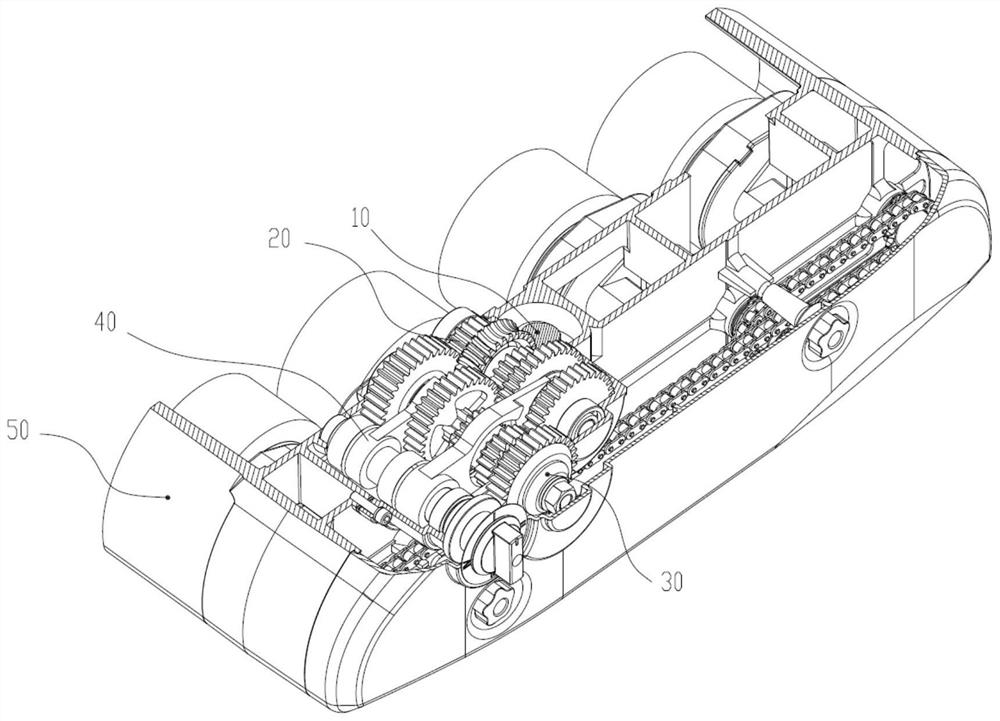

[0028] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the combined gearbox 100 includes an input module 10 (a motor in this embodiment), a transmission module 20 , an output module 30 and a casing 50 . Such as Figure 4 As shown, the box body 50 is composed of a casing 510 and a box cover 530 , and a sealing gasket 520 is provided at the joining plane of the casing 510 and the box cover 530 . The housing 510 and the case cover 530 are provided with positioning pin holes 532, the case cover 530 is provided with fixing holes 533, and the corresponding positions of the housing 510 are provided with threaded holes; positioning screws (such as shoulder screws) 550 with positioning pin rods Pass through the positioning pin hole 532 and the screw 540 pass through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com