Antibacterial anti-static silk fabric and production process thereof

An anti-static and anti-static fiber technology, applied in the field of silk fabrics, can solve the problems of easy dust absorption, unfavorable use, poor anti-bacterial effect, etc., and achieve the effect of strong anti-static effect, good anti-static effect, and good anti-bacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An antibacterial and antistatic silk fabric, comprising the following raw materials in parts by weight: 500 parts of raw silk, 100 parts of detergent solution, 100 parts of sodium carbonate solution, 200 parts of antistatic fiber, 100 parts of cotton fiber, 80 parts of bamboo fiber, and 80 parts of chitin fiber 60 parts of nano antibacterial biological protein fiber, 50 parts of silver fiber, 100 parts of organic silicon quaternary ammonium antibacterial agent, 200 parts of PU resin, and 100 parts of antistatic coating.

Embodiment 2

[0027] An antibacterial and antistatic silk fabric, comprising the following raw materials in parts by weight: 800 parts of raw silk, 200 parts of detergent solution, 150 parts of sodium carbonate solution, 300 parts of antistatic fiber, 130 parts of cotton fiber, 100 parts of bamboo fiber, and 100 parts of chitin fiber 80 parts of nano antibacterial biological protein fiber, 80 parts of silver fiber, 200 parts of organic silicon quaternary ammonium antibacterial agent, 300 parts of PU resin, and 200 parts of antistatic coating.

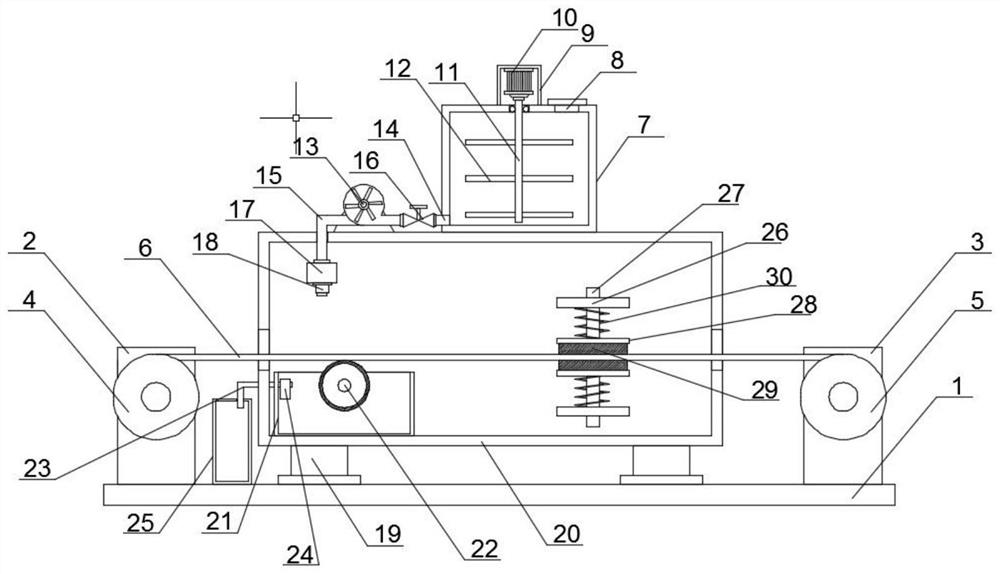

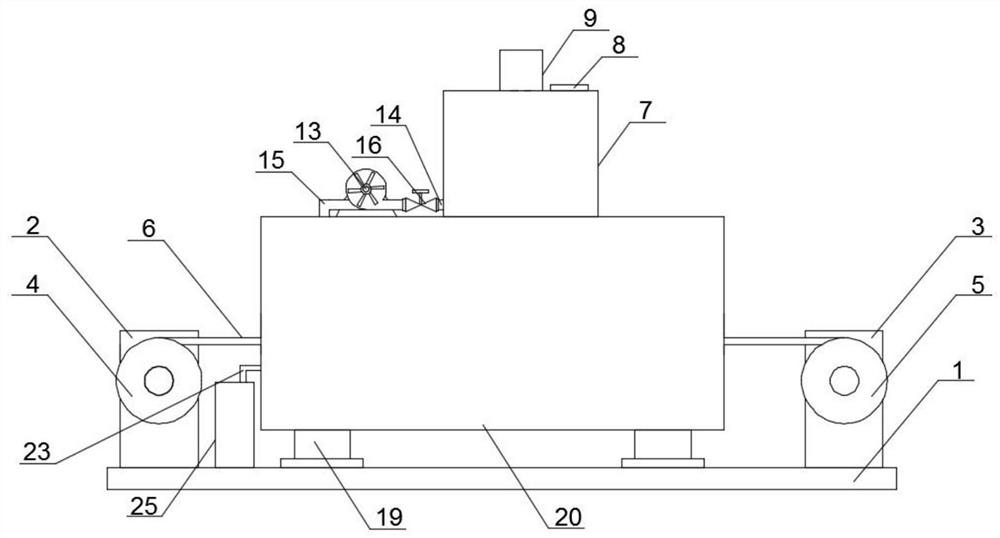

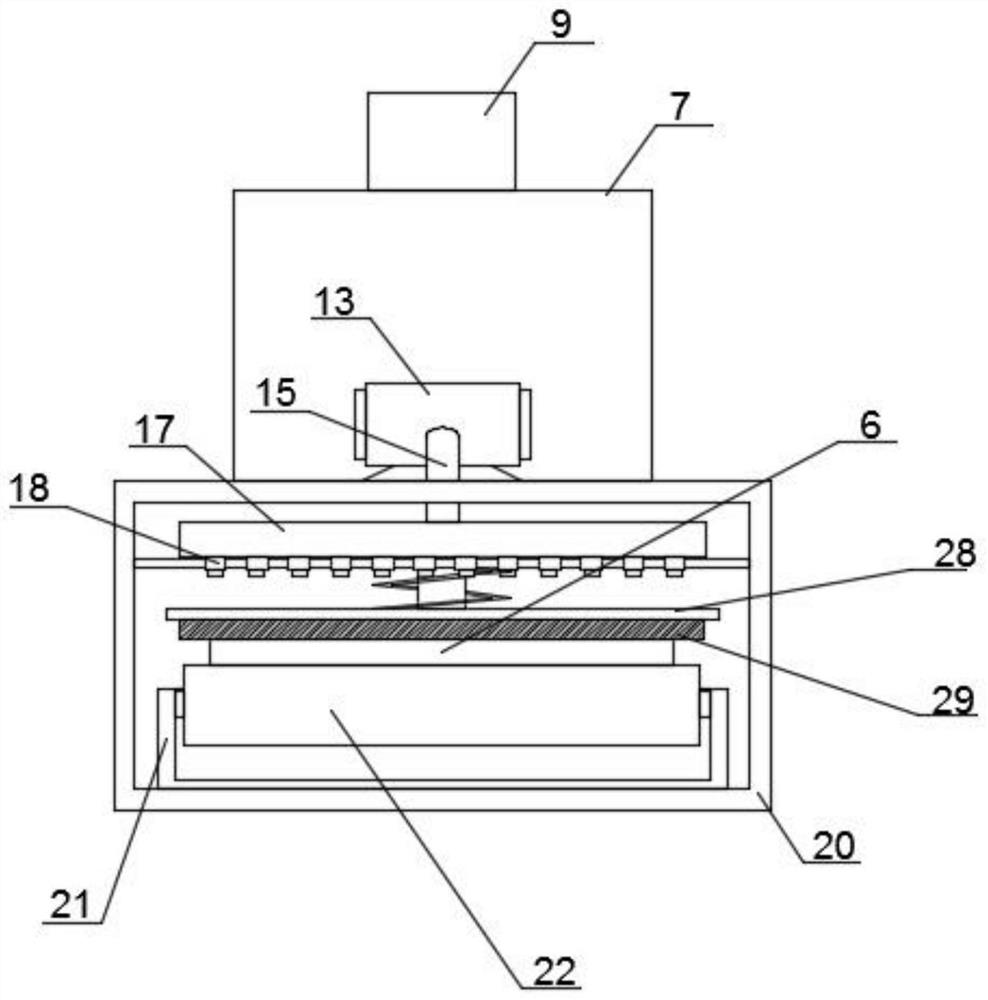

[0028] refer to Figure 1-3 , a kind of production technology of antibacterial antistatic silk fabric, comprises the following steps:

[0029] S1. Put the raw silk in the above parts by weight into the refining tank, then stir and mix the detergent solution in the above parts by weight with the sodium carbonate solution evenly for 5-10 minutes, and add the stirred mixed solution to the inside of the refining tank, Then control the heating of the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com