Titanium dioxide-coated ferric oxide hollow microsphere composite material and its preparation method and application

A technology of triiron tetroxide and titanium dioxide, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high density and poor impedance matching characteristics, and achieves a simple preparation process, good electromagnetic wave absorption performance, and easy-to-obtain raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In a second aspect, the present invention provides a method for preparing the titanium dioxide-coated ferric oxide hollow microsphere composite material, comprising the following steps:

[0033] Disperse the hollow microspheres of iron ferric oxide nanometer in absolute ethanol, and disperse evenly to obtain a dispersion liquid;

[0034] Add tetrabutyl titanate dropwise to the dispersion, and mix evenly to obtain a mixed solution;

[0035] Add deionized water to the second container, place the first container containing the mixed solution in the deionized water, separate the mixed solution and the deionized water by the side wall of the first container, and separate the second container as a whole Transfer to the reaction kettle, heat treatment at high temperature, and carry out the reaction to obtain titanium dioxide-coated hollow ferric oxide microsphere composite material.

[0036] In some embodiments, the preparation method of nano ferric oxide comprises the follow...

Embodiment 1

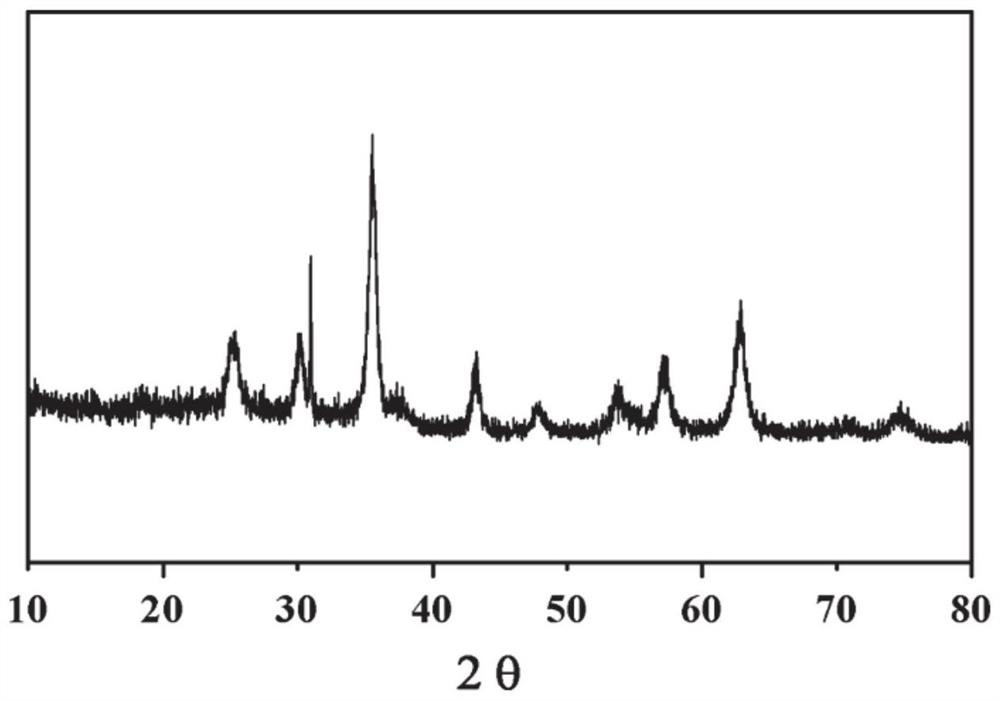

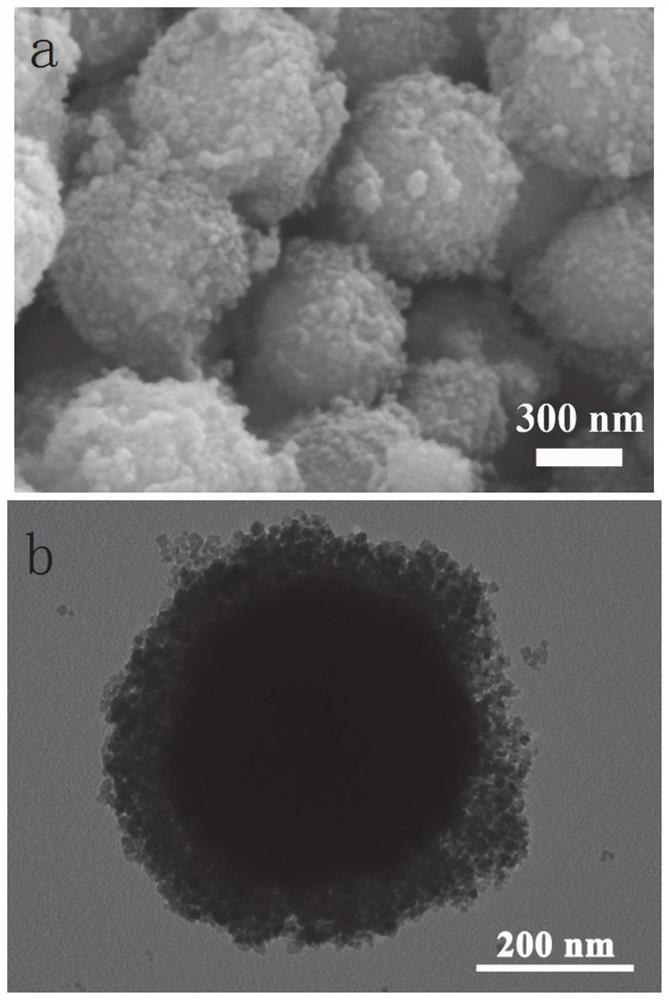

[0056] A preparation method of an electromagnetic wave absorber filled with ferric oxide coated with titanium dioxide, comprising the steps of:

[0057] (1) Dissolve 0.64g of sodium dodecylbenzenesulfonate (SDBS) in 64mL of ethylene glycol, and stir continuously for 30min until a clear and transparent homogeneous solution is obtained.

[0058] (2) 2.16g of ferric chloride hexahydrate and 3.72g of sodium acetate were successively dissolved into the solution in step (1), and stirred continuously for 2 hours until a uniform solution was obtained.

[0059] (3) Transfer all the solution in step (2) to a polytetrafluoroethylene-lined steel reaction kettle, and heat to 180° C. for 24 h. The obtained solid product was centrifuged, washed several times with ethanol / water mixture, and then dried under vacuum at 60° C. for 8 h.

[0060] (4) Take 0.1 g of the sample obtained in step (3), add it into 25 mL of absolute ethanol, ultrasonicate for 5 min, and continuously stir for 30 min unti...

Embodiment 2

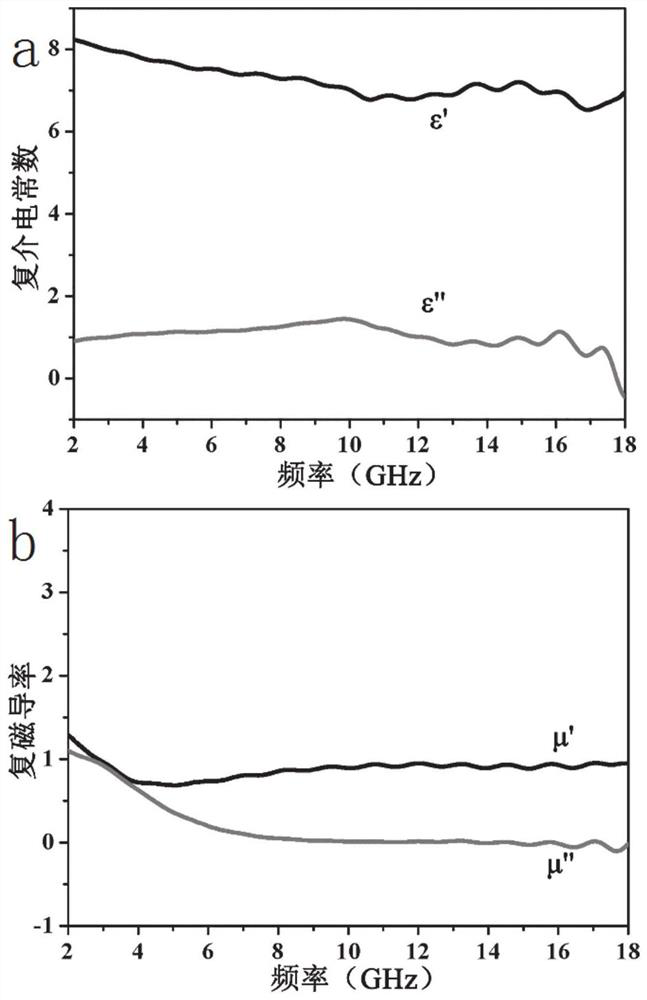

[0069] Compared with Example 1, the product obtained in step (7) is mixed with paraffin at a mass ratio of 1:2, and other conditions remain unchanged. After the solid paraffin is melted at a temperature above 75°C, it is stirred quickly and evenly After cooling to room temperature, it is compressed into an absorbent body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com