Method for removing tetracycline in wastewater

A technology for tetracycline and waste water, which is applied in chemical instruments and methods, water pollutants, special compound water treatment, etc., can solve the problems of complicated preparation process, high preparation cost, and low use efficiency, and achieve good effect, low cost, and reduced Effects of pollution and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

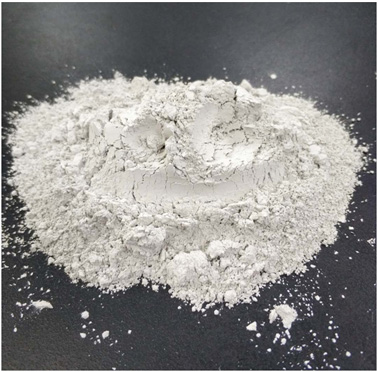

[0023] (1) Wash the discarded egg shells with clean water, then soak them in 0.1 M NaOH solution at 30 °C for 20 h, take them out, wash and dry them, grind them into powder, and sieve them through a 50-mesh sieve for later use;

[0024] (2) Take 10 mg of prepared egg shell powder, add it to 50 mL of wastewater containing 10 mg / L tetracycline, and stir to mix evenly;

[0025] (3) The mixed solution in step (2) was first reacted for 30 min under dark reaction conditions, and then treated with sunlight for 120 min.

[0026] After testing, the degradation rate of tetracycline in wastewater is 94%, which proves that it can effectively reduce the content of tetracycline in wastewater.

Embodiment 2

[0028] (1) Wash the discarded egg shells with clean water, then soak them in 0.5 M NaOH solution at 40 °C for 15 hours, take them out, wash and dry them, grind them into powder, and sieve them through a 100-mesh sieve for later use;

[0029] (2) Take 20 mg of prepared egg shell powder, add it to 50 mL of wastewater containing 20 mg / L tetracycline, and stir with a magnetic force;

[0030] (3) The mixed solution in step (2) was first reacted for 30 min under dark reaction conditions, and then treated with sunlight for 120 min.

[0031] After testing, the degradation rate of tetracycline in wastewater is 95%, which proves that it can effectively reduce the content of tetracycline in wastewater.

Embodiment 3

[0033] (1) Wash the discarded egg shells with clean water, then soak them in 1.0 M NaOH solution at 60 °C for 12 hours, take them out, wash them, dry them, grind them into powder, and sieve them through a 200-mesh sieve for later use;

[0034] (2) Take 30 mg of prepared egg shell powder, add it to 50 mL of wastewater containing 30 mg / L tetracycline, and stir to mix evenly;

[0035] (3) The mixed solution in step (2) was first reacted for 30 min under dark reaction conditions, and then treated with sunlight for 120 min.

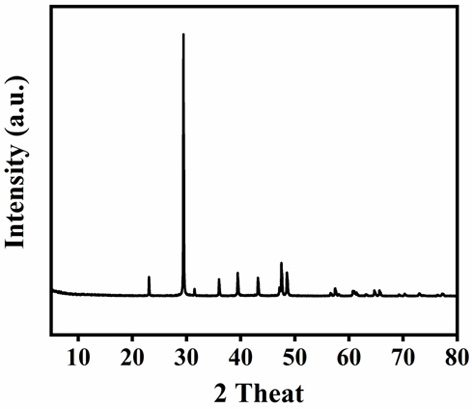

[0036] figure 2 It is the X-ray diffraction pattern of the prepared egg shell powder. As can be seen from the figure, its main component is CaCO 3 .

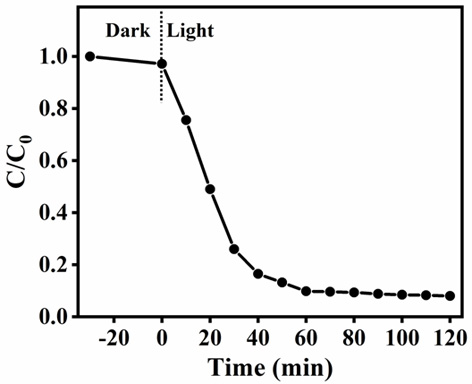

[0037] Step (3) During the treatment process, measure the content of tetracycline in the solution every 10 minutes, and draw the curve of the content changing with time, the results are as follows image 3 . From image 3 It can be seen that with the prolongation of the light time, the content of tetracyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com