A distribution conveying system for sauce production

A conveying system and sauce technology, which is applied in the direction of liquid materials, transportation and packaging, packaging, etc., can solve the problems of waste conveying pressure of sauce, increased maintenance cost, low work efficiency, etc., to reduce pressure accumulation, protect equipment, and continuously The effect of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

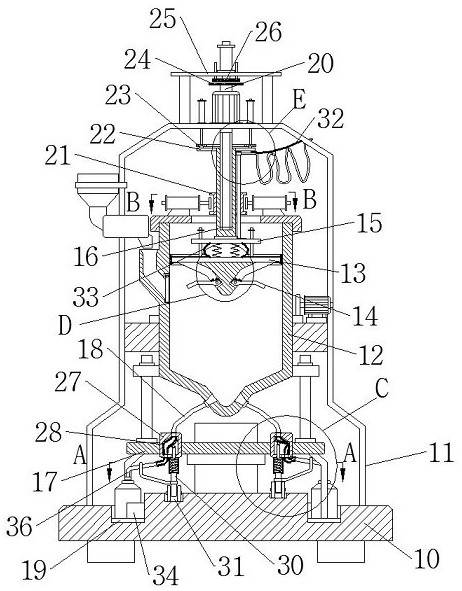

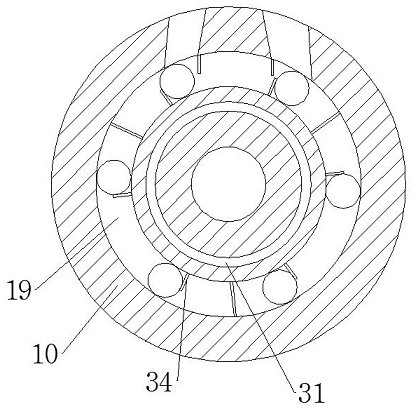

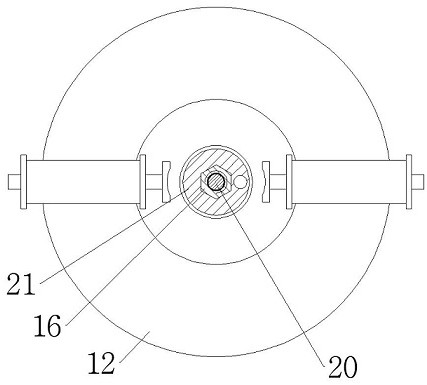

[0022] Such as Figure 1-Figure 7 As shown, the specific structure of the present invention is: a distribution and conveying system for sauce production, including a base 10, the top of the base 10 is fixedly provided with a support rod 11, and the top surface of the base 10 is provided with a vertical The storage cylinder 12 that stores the sauce that rotates on a straight axis, the storage cylinder 12 and the support rod 11 rotate with each other, the storage cylinder 12 is provided with an entrance for inputting the sauce into the storage cylinder 12, the The storage tube 12 is connected with a dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com