Coal pressurized gasification equipment

A pressurized gasification of crushed coal, pressurized gasification technology, applied in the direction of gasification process, gasification device feeding tools, electrical program control, etc., can solve problems such as inappropriateness, improve the degree of automation, save manpower, The effect of reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

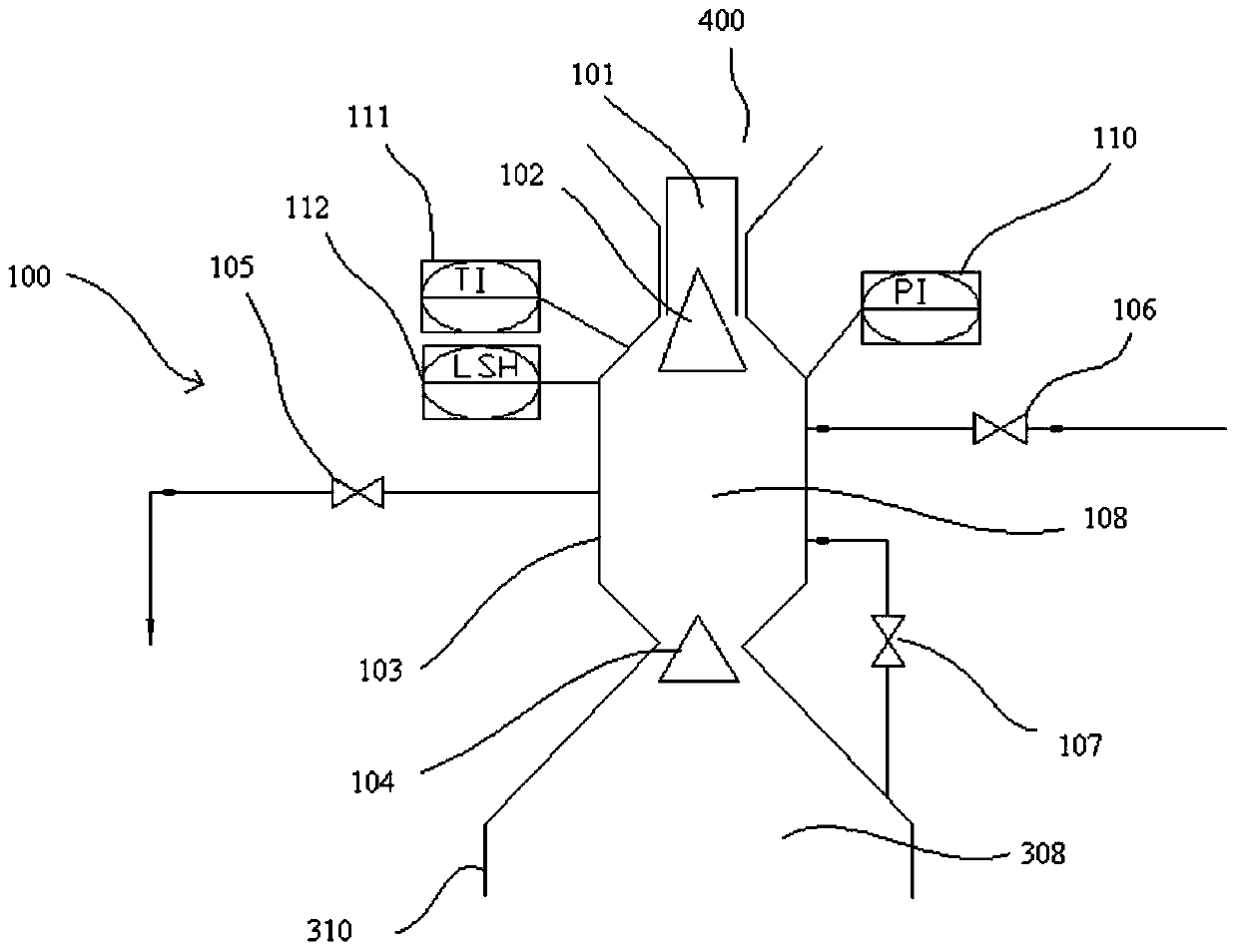

[0105] figure 1 A schematic structural view of a coal lock mechanism 100 of a 4.0 MPa pulverized coal pressurized gasification device according to an embodiment of the present invention is shown.

[0106] In actual operation, as figure 1 The shown coal lock mechanism 100 can realize the automatic control of the system through the following steps:

[0107] Nesting process

[0108] 1. Nesting

[0109] Permissible conditions: the pressure is completed, the coal lock pressure relief valve 105, the coal lock primary pressure valve 106, the coal lock upper valve 102, the coal lock secondary pressure valve 107, and the coal lock cylinder valve 101 are closed.

[0110] Action: open the lower valve 104 of the lower coal lock, and start the timer at the same time.

[0111] Result: The coal lock lower valve 104 is fully opened within 10 seconds of the timing time, and the coal lock pressure is greater than 3800KPa. After the conditions are met, enter the first step of automatic co...

Embodiment 2

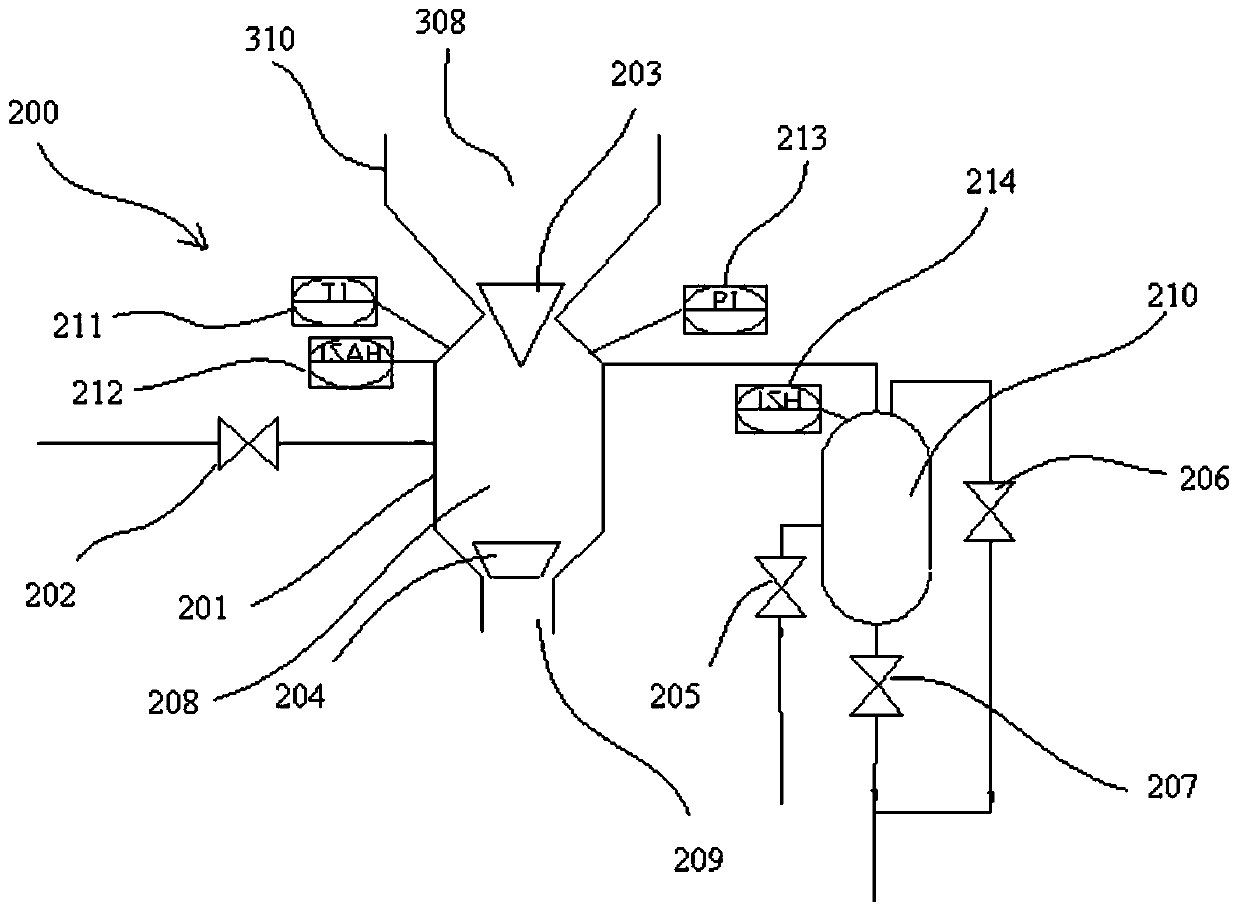

[0151] figure 2 A schematic diagram of an ash lock mechanism 200 of a 4.0 MPa pulverized coal pressurized gasification device according to an embodiment of the present invention is shown.

[0152] in, figure 2 The control method of the ash lock mechanism 200 is as follows: when the ash lock is high, close the ash lock upper valve 203, open the ash lock primary pressure relief valve 206, and open the ash lock secondary pressure relief valve 207 when the pressure is less than or equal to 200KPa; When the ash lock is released to normal pressure, open the ash lock lower valve 204, the ash slag is discharged into the slag ditch, and open the ash steam expansion cooler water filling valve 205; when the ash lock empties the ash slag and the ash steam expansion cooler 210 flush After the liquid level is normal, close the ash lock lower valve 204 and open the ash lock pressure filling valve 202; The ash in the inner cavity 308 is discharged into the ash lock mechanism 200 by its ow...

Embodiment 3

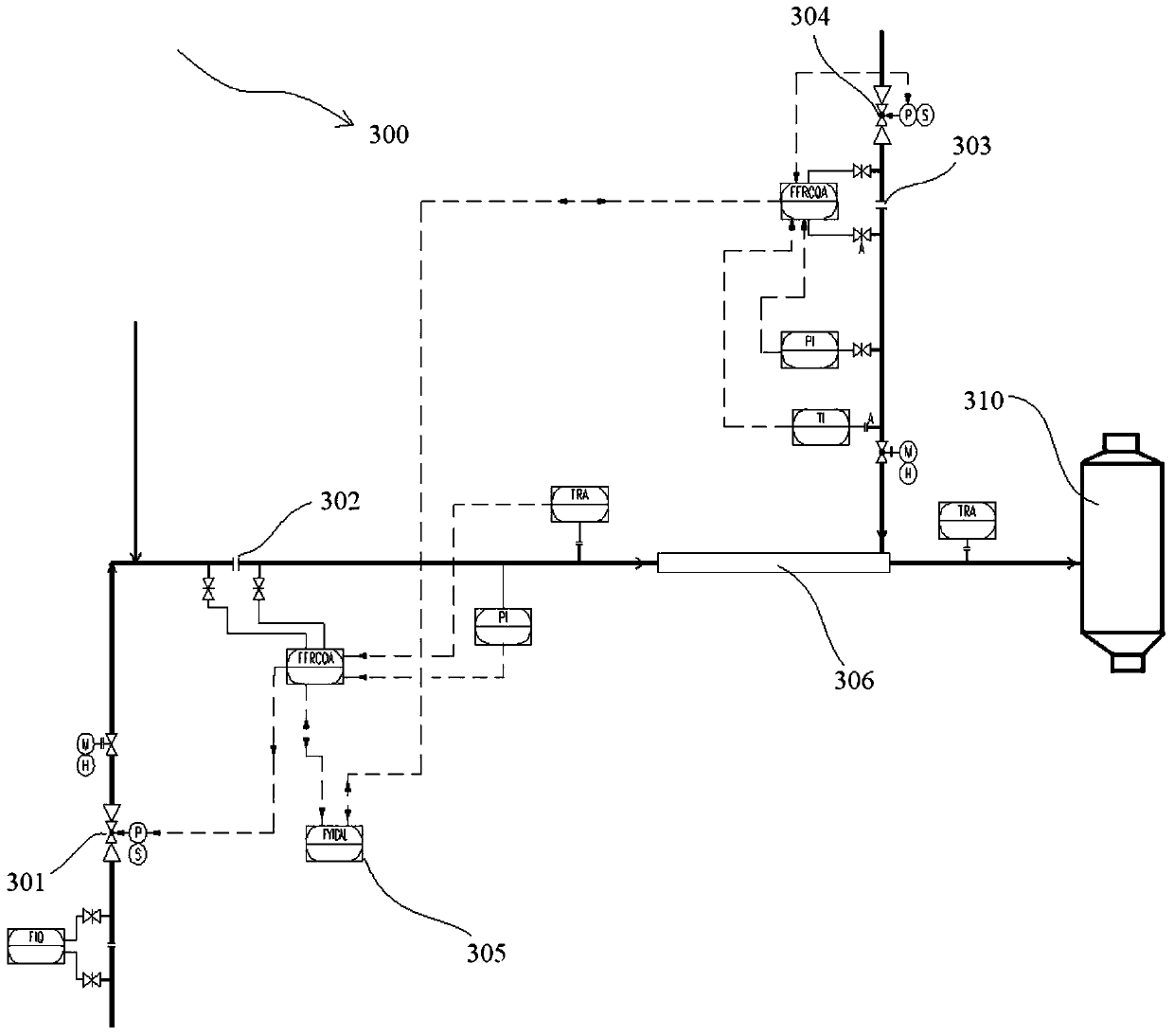

[0195] image 3 A schematic diagram of a gasifier mechanism 300 of a 4.0 MPa pulverized coal pressurized gasification plant is shown.

[0196] image 3 The gasifier mechanism 300 shown in is used for automatic control of the load up and down of the gasifier mechanism 300 . The control method of the gasifier mechanism 300 is as follows: a) When the gasifier mechanism 300 operates stably, the oxygen flow rate is greater than 2000Nm 3 / h, manually input a certain steam-oxygen ratio value on the steam-oxygen ratio regulator 305; b) when the gasifier mechanism 300 is lifting or lowering the load, manually input the gasifier load target value on the gasification agent oxygen flowmeter 303 , the gasifying agent oxygen flow meter 303 automatically adjusts the gasifying agent oxygen regulating valve 304 to automatically switch to achieve the gasification furnace load target value; c) at the same time, the gasifying agent steam flow meter 302 will The required steam flow is automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com